Novel polyimide high polymer material based on 2,5-diallyloxy p-phenylenediamine monomer and preparation method of novel polyimide high polymer material

A technology of diallyloxy-p-phenylenediamine and diallyloxydiamino, which is applied in the field of new polyimide polymer materials and its preparation, and can solve the problem of gas permeability and gas selectivity. Long, reduce performance, plasticization and other issues, to achieve the effect of improving separation performance and plasticization resistance, improving anti-plasticization performance, and improving separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

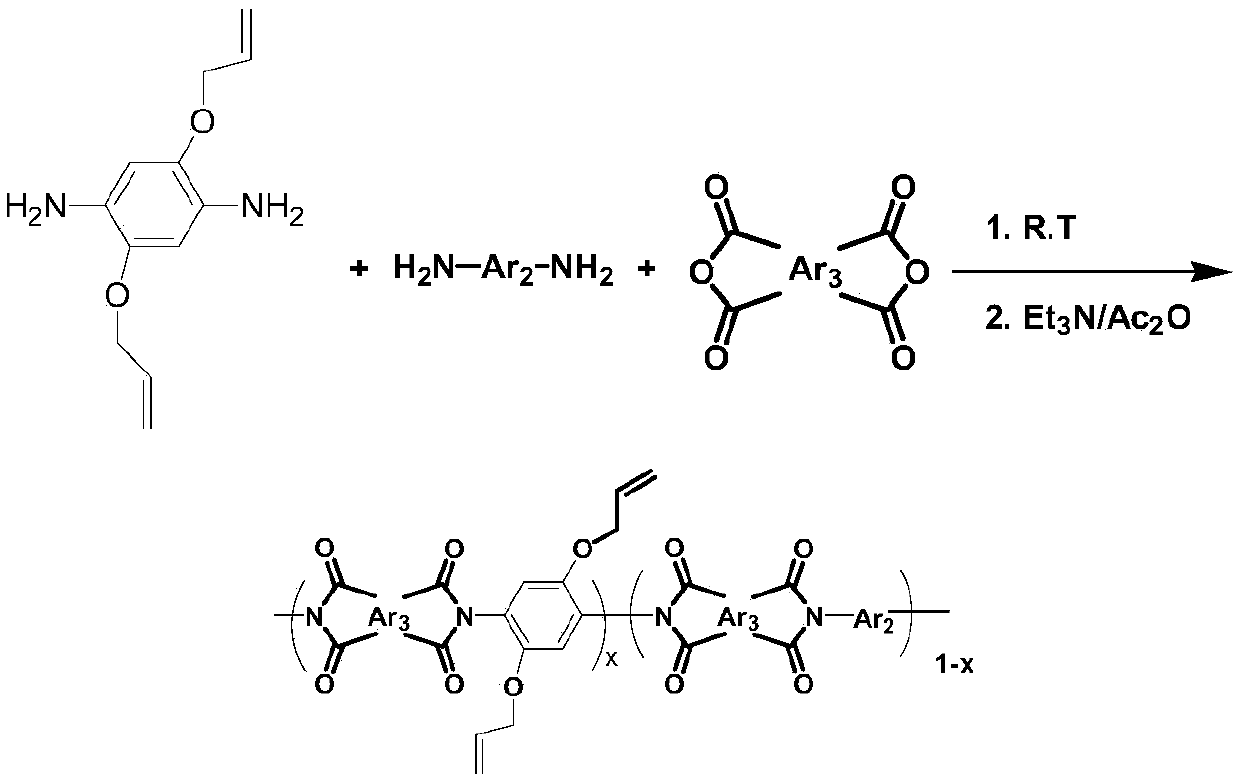

[0059] In this embodiment, the novel polyarylimide resin material of allyloxy group has the following repeating structural unit:

[0060]

[0061] The specific preparation method is as follows: when equipped with stirring paddle, drying tube and N 2 Add 50ml of solvent N-methylpyrrolidone and 12.50mmol (2.7500g) of 2,5-diallyloxy-p-phenylenediamine to the three-necked flask at the inlet, stir to dissolve them all, and add 12.50mmol of 6FDA anhydride under ice bath (5.5500g), the mixture was stirred under ice bath for 1h, removed the ice bath, stirred at room temperature for 12h, added Et 3 N and Ac 2 O (1.25ml and 2.50ml), stirred at room temperature for 24h and at 80°C for 3h. The mixture was poured into 700ml of methanol for precipitation, washed three times with methanol and then vacuum-dried at 80° C. for 24 hours to obtain 6.72 g of yellow-white polymer ANPI-6FDA with a yield of 86%.

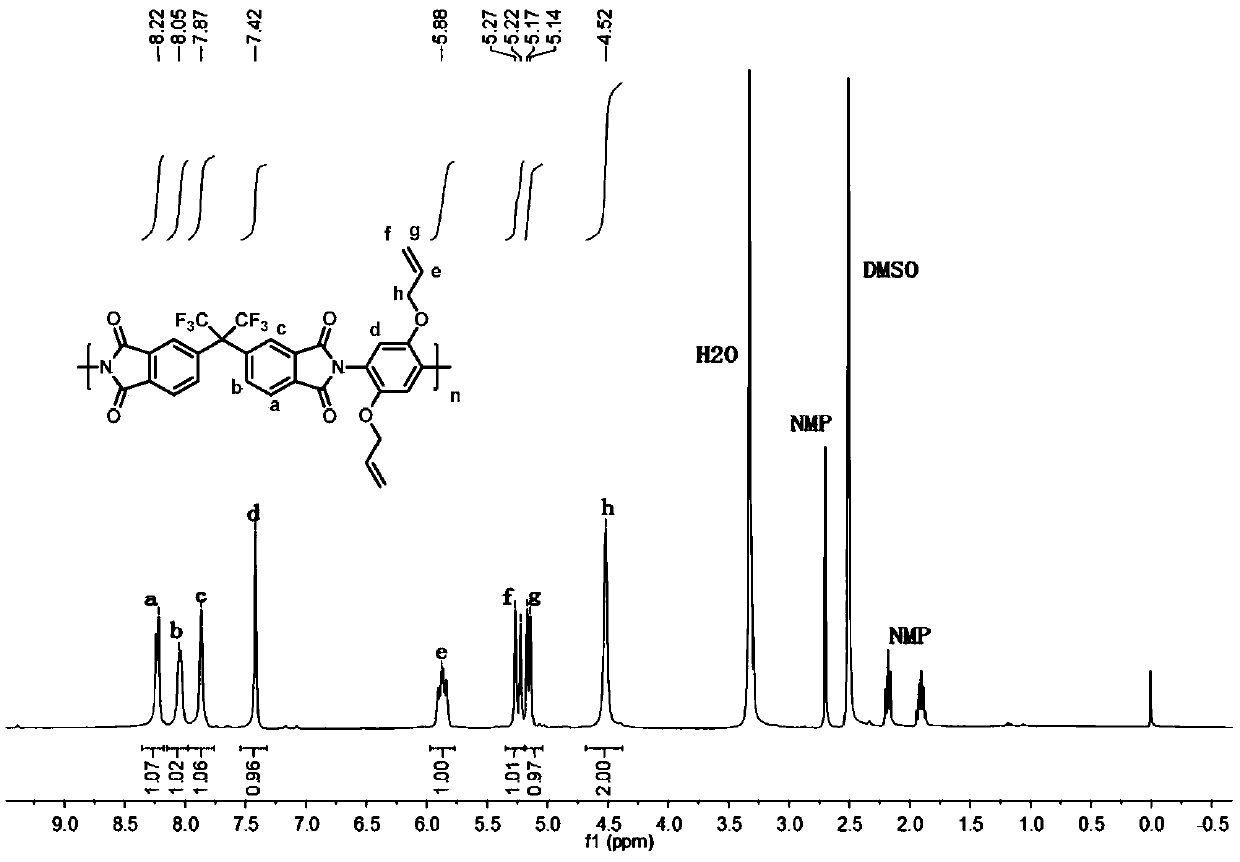

[0062] image 3 The proton nuclear magnetic resonance spectrum of the novel arom...

Embodiment 2

[0065] In this example, the novel polyarylimide resin material containing hydroxyl and allyl groups has the following repeating structural units:

[0066]

[0067] The specific preparation method is as follows: add 500 mg of the polymer ANPI-6FDA prepared in Example 1 to the polymerization tube, vacuum three times with nitrogen, seal the tube under vacuum conditions, and place it in a 250° C. sand bath for 6-8 hours of reaction. After the reaction was completed, the polymerization tube was broken to obtain 500 mg of the polymer CRNPI-6FDA, with a yield of nearly 100%.

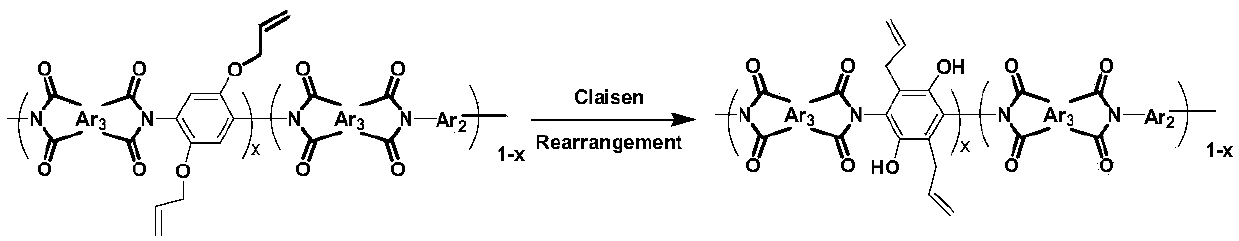

[0068] Figure 4 The proton nuclear magnetic resonance spectrum of the novel aromatic polyimide (CRNPI-6FDA) containing hydroxyl and allyl group prepared in embodiment 2;

[0069] Figure 4 Among them, the peaks in the spectrum can be well assigned to the molecular structure, and the integral area and the peak position correspond reasonably. After the Claisen rearrangement, the OH peak appears at 9.0ppm; ...

Embodiment 3

[0071] In this embodiment, the novel polyarylimide film of allyloxy group has the following repeating structural units:

[0072]

[0073] The specific preparation method is as follows: 1.00 g of ANPI-6FDA polymer is dissolved in 20 ml of dichloromethane, and filtered through a 20 μm polytetrafluoroethylene filter membrane to obtain a clear orange solution. Add the solution dropwise on a clean flat glass to make the solution cover evenly, and slowly evaporate the solvent. After the film is formed, put it in a vacuum oven for heat treatment at 80°C-200°C in stages, take it out, put it in water, and peel it off to obtain a film.

[0074] Figure 5 The ATR-IR spectrum of the allyloxy-containing novel aromatic polyimide film (ANPI-6FDA) prepared in Example 3.

[0075] at 1789 and 1724cm -1 The stretching vibration peak attributed to imide C=O appears at 1625cm -1 The peak is the vibration peak of the benzene ring skeleton. Show above, polymkeric substance has typical polyim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com