Preparation method of super absorbent composite resin with functions of preventing soil skin shrinkage and reducing water evaporation

A super absorbent, composite resin technology, applied in the preparation of super absorbent resin, in the field of super absorbent resin, can solve the problems of high use price, environmental pollution, and refractory degradation of mulch film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

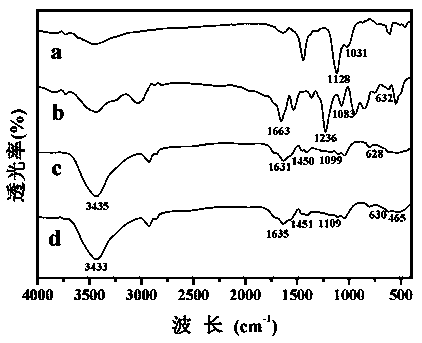

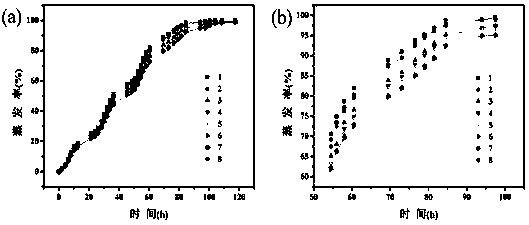

[0035] Embodiment 1, preparation of methylcellulose-graft-poly(acrylic acid-copolymerization-diacetone acrylamide) / attapulgite superabsorbent resin composite material

[0036] (1) Add 30 mL of distilled water and 0.576 g of methylcellulose into a four-necked flask equipped with mechanical stirring, and stir evenly to obtain a dispersion. Under continuous stirring, 0.72 g of attapulgite was added, and the solution was heated to 60 °C for 60 min. Cool the reactant to 50 °C, add 0.0432 g of potassium persulfate (dissolved in 4 mL of water), and stir for 10 min, the reaction will contain 7.2 g of acrylic acid (neutralization degree is 60%), 1.08 g of diacetone acrylamide and 0.0072 g The mixed solution of N,N-methylenebisacrylamide was dropped into the above system, and then the temperature was slowly raised to 80 °C, and the reaction was carried out at constant temperature for 3 h. Nitrogen was used throughout the experiment. After the reaction, the obtained product was dried a...

Embodiment 2

[0040] Embodiment 2, preparation of hydroxyethyl cellulose-graft-poly(acrylic acid-copolymerization-N-methylolacrylamide) / montmorillonite superabsorbent resin composite material

[0041] (1) Add 40 mL of distilled water and 0.864 g of hydroxyethyl cellulose into a four-neck flask equipped with mechanical stirring, and stir evenly to obtain a dispersion. With continuous stirring, 0.144 g of montmorillonite was added, and the solution was heated to 80 °C for 30 min. Cool the reactant to 50 °C, add 0.072 g of potassium persulfate (dissolved in 7 mL of water), and stir for 10 min, 7.2 g of acrylic acid (neutralization degree is 80%), 1.44 g of N-methylolacrylamide and 0.0108 g N,N-methylenebisacrylamide mixed solution was dropped into the above system, then slowly heated to 60°C, and reacted at constant temperature for 5 h. Nitrogen was used throughout the experiment. After the reaction, the obtained product was dried at 80°C to constant weight, pulverized, and passed through a ...

Embodiment 3

[0045] Embodiment 3, preparation of hydroxypropyl methylcellulose-graft-poly(acrylic acid-copolymerization-N-isopropylacrylamide) / kaolin superabsorbent composite resin

[0046] (1) Add 35 mL of distilled water and 0.72 g of hydroxypropyl methylcellulose into a four-necked flask equipped with mechanical stirring, and stir evenly to obtain a dispersion. With continuous stirring, 0.576 g of kaolin was added, and the solution was heated to 80 °C for 30 min. Cool the reactant to 50 °C, add 0.0576 g of potassium persulfate (dissolved in 6 mL of water), and stir for 10 min, 7.2 g of acrylic acid (neutralization degree is 70%), 1.8 g of N-isopropylacrylamide A mixed solution of 0.0087 g N,N-methylenebisacrylamide was dropped into the above system, then the temperature was raised slowly to 60°C, and the reaction was carried out at a constant temperature for 5 h. Nitrogen was used throughout the experiment. After the reaction, the obtained product was dried at 60°C to constant weight,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com