Production method of cast-state low-temperature ball iron

A production method and low-temperature technology are applied in the production field of as-cast low-temperature ductile iron, which can solve the problems of reducing toughness, increasing casting cost, and high production cost, and achieving the effects of high safety, production safety and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

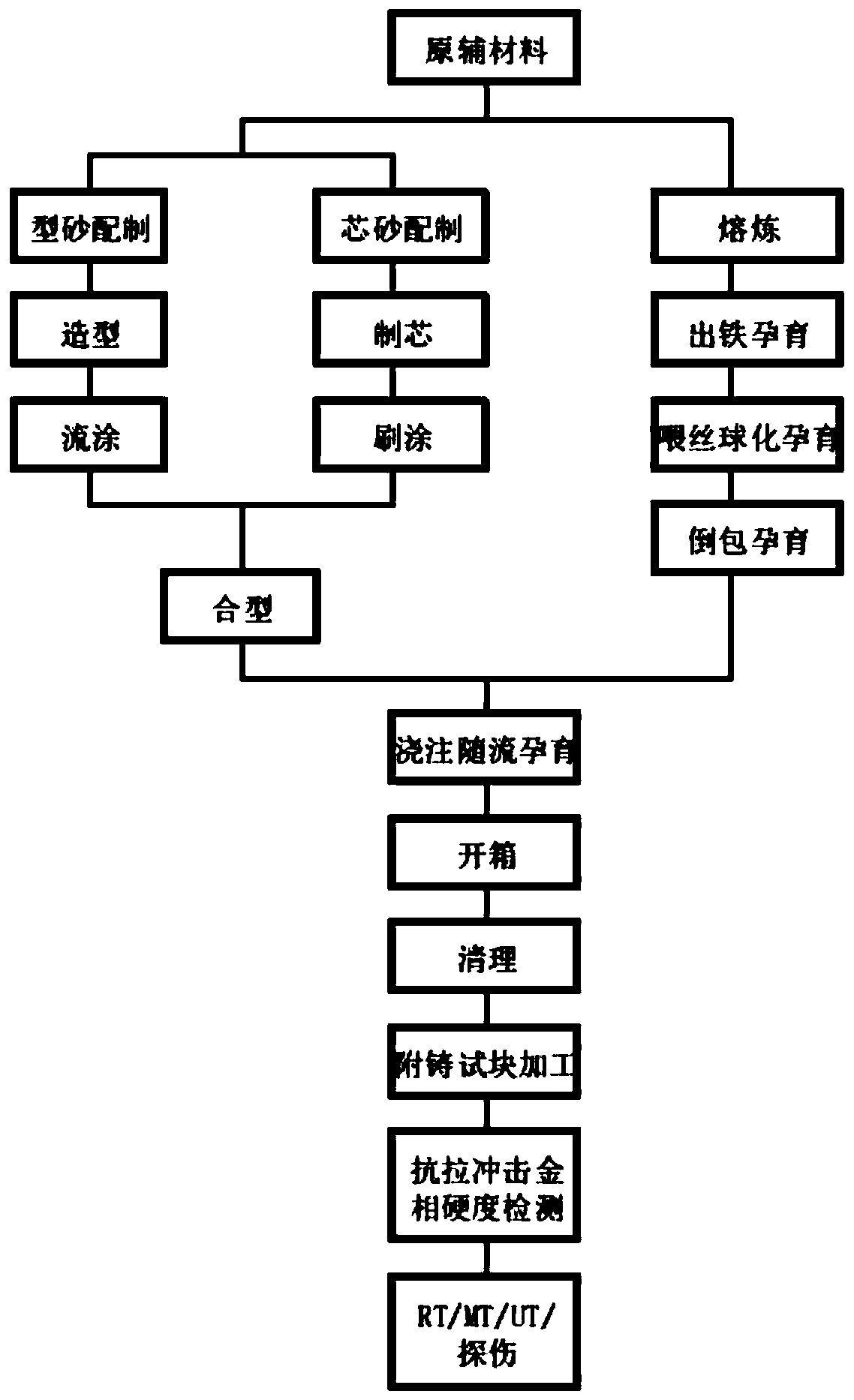

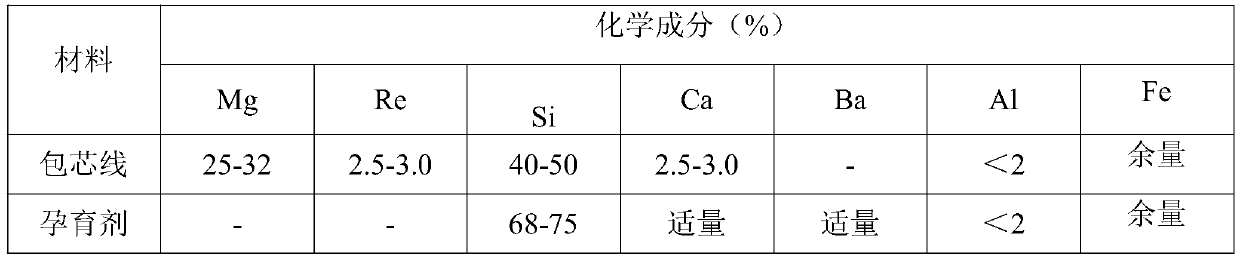

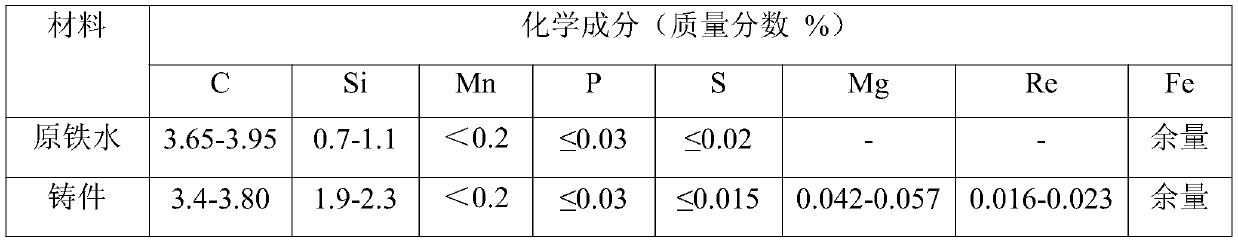

[0043] The production method of as-cast low-temperature ductile iron according to the present invention adopts raw and auxiliary materials selection → molding, core making → flow coating → box closing → electric furnace smelting → furnace inoculation → silk feeding spheroidal inoculation → pouring inoculation → pouring with flow Breeding→unpacking→cleaning→attached casting sample processing and inspection process preparation.

[0044] The raw and auxiliary materials include pig iron, steel scrap, furnace charge, recarburizer, cored wire, inoculant, new sand, resin, curing agent and heating and heat preservation riser.

[0045] The chemical composition of the pig iron is selected according to the mass fraction of high-quality Q10 pig iron with Si<1%, Mn<0.2%, P<0.03%, and S≤0.02%.

[0046] The steel scrap is high-quality carbon steel scrap with low manganese (Mn<0.10wt%) and low sulfur and phosphorus, such as leftover briquettes for stamping.

[0047] Raw materials must be pur...

Embodiment 2

[0067] The production method of as-cast low-temperature ductile iron according to the present invention adopts raw and auxiliary materials selection → molding, core making → flow coating → box closing → electric furnace smelting → furnace inoculation → silk feeding spheroidal inoculation → pouring inoculation → pouring with flow Breeding→unpacking→cleaning→attached casting sample processing and inspection process preparation.

[0068] The raw and auxiliary materials include pig iron, steel scrap, furnace charge, recarburizer, cored wire, inoculant, new sand, resin, curing agent and heating and heat preservation riser.

[0069] The chemical composition of the pig iron is selected according to the mass fraction of high-quality Q10 pig iron with Si<1%, Mn<0.2%, P<0.03%, and S≤0.02%.

[0070] The steel scrap is high-quality carbon steel scrap with low manganese (Mn<0.10wt%) and low sulfur and phosphorus, such as leftover briquettes for stamping.

[0071] Raw materials must be pur...

Embodiment 3

[0091] The production method of as-cast low-temperature ductile iron according to the present invention adopts raw and auxiliary materials selection → molding, core making → flow coating → box closing → electric furnace smelting → furnace inoculation → silk feeding spheroidal inoculation → pouring inoculation → pouring with flow Breeding→unpacking→cleaning→attached casting sample processing and inspection process preparation.

[0092] The raw and auxiliary materials include pig iron, steel scrap, furnace charge, recarburizer, cored wire, inoculant, new sand, resin, curing agent and heating and heat preservation riser.

[0093] The chemical composition of the pig iron is selected according to the mass fraction of high-quality Q10 pig iron with Si<1%, Mn<0.2%, P<0.03%, and S≤0.02%.

[0094] The steel scrap is high-quality carbon steel scrap with low manganese (Mn<0.10wt%) and low sulfur and phosphorus, such as leftover briquettes for stamping.

[0095] Raw materials must be pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com