Micronano zirconia fiber and preparation method thereof

A zirconia fiber, micro-nano technology, applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of high cost, cumbersome operation steps, and many types of raw materials for the obtained fibers and their products, and achieve easy large-scale production and process. Simple routes and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A method for preparing micro-nano zirconia fibers, the steps are as follows:

[0079] (1) Preparation of zirconia fiber precursor sol

[0080] Under the condition that the temperature of the water bath is 28°C, add 1000g of basic zirconium carbonate and 300g of glacial acetic acid, the adding time is 6h, and the stirring speed is 200r / min. Sol, after that, add 10gPEO, continue to stir for 6h to form a transparent sol, filter to remove insoluble impurities, let it stand for 2h, the obtained colorless and transparent filtrate is the zirconia fiber precursor sol;

[0081] (2) Preparation of zirconia fibers

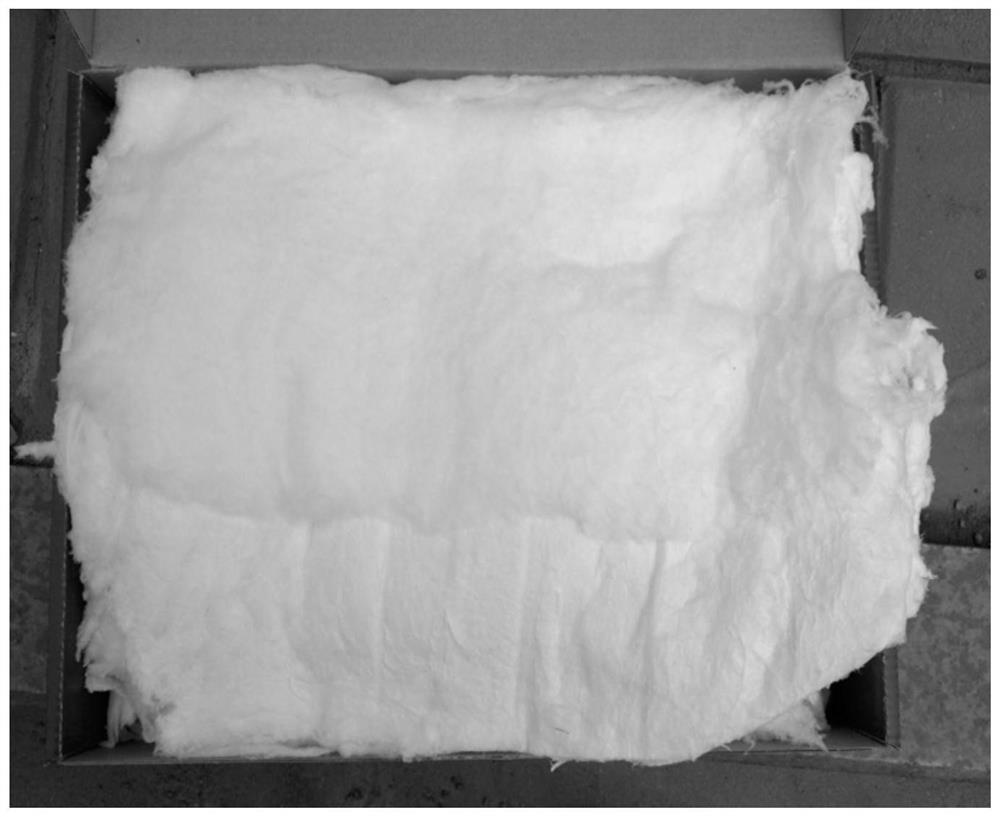

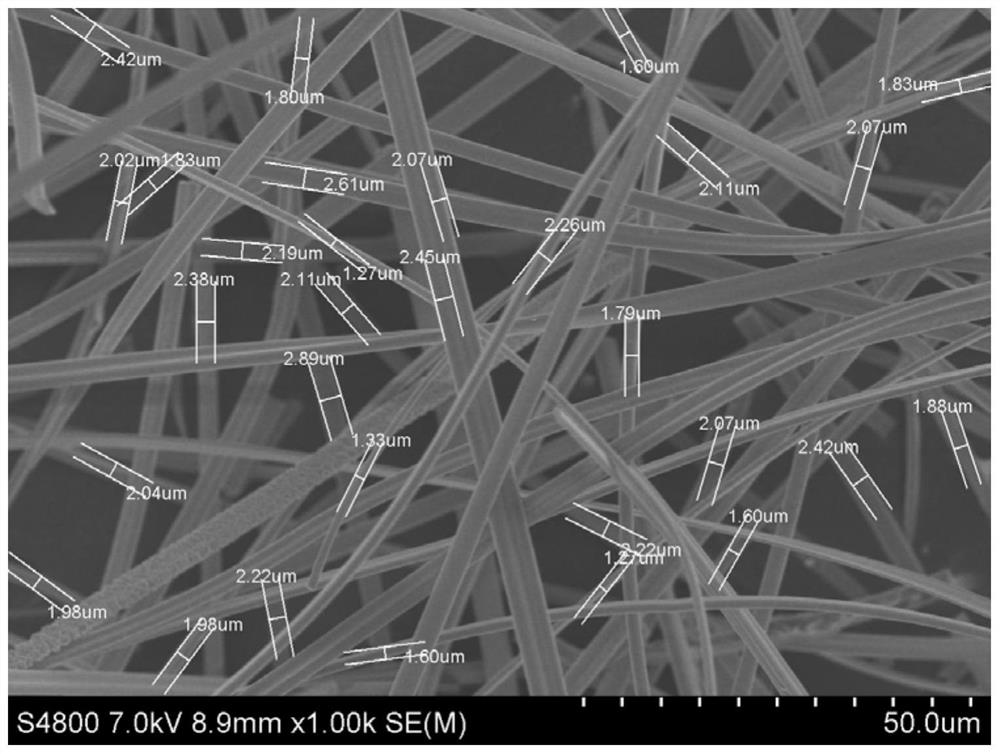

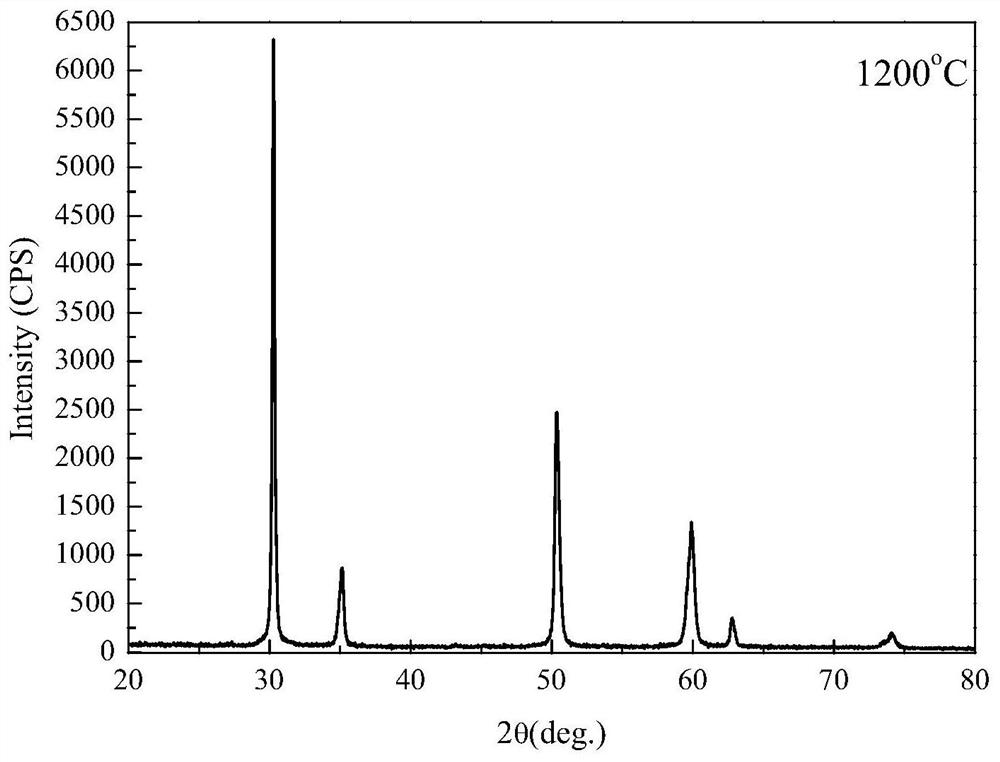

[0082] Using centrifugal spinning technology, the speed of the centrifuge is 11000r / min, the diameter of the spinning hole is 0.04, the ambient temperature is 35°C, and the relative humidity is 29%. Uniform drafting by centrifugal force to obtain zirconia precursor fibers; zirconia precursor fibers are heat-treated at high temperature, heated up to 1200°C, kept at 12...

Embodiment 2

[0084] As described in Example 1, the difference is that the standing time in step (1) is adjusted to 4h. Zirconia fibers similar to those in Example 1 were obtained.

Embodiment 3

[0086] As described in Example 1, the difference is that the diameter of the spinning hole in step (2) is 0.05 mm, and the obtained zirconia fiber has a diameter of 2 to 4 μm, an average diameter of 3.65 μm, and a length of 1 to 40 cm (such as Figure 5 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com