Wear-resistant coating and preparation method thereof, cutter ring of shield hob, shield hob and shield machine

A wear-resistant coating, shield hob technology, applied in the direction of coating, metal material coating process, mining equipment, etc., can solve the problems of high coating cost, large thermal stress, large heat output of surfacing welding, etc. Inhibits germination and expansion, enhances binding strength, and effects of fast heating rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of wear-resistant coating provided by the present invention comprises the following steps:

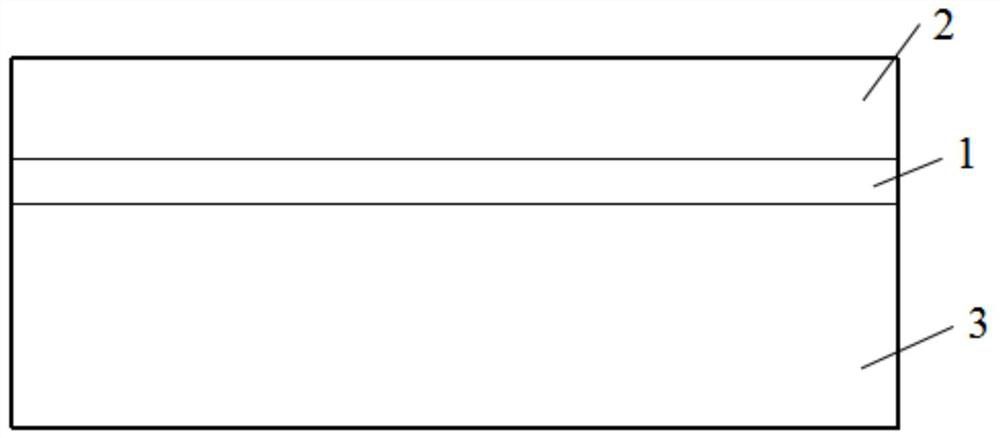

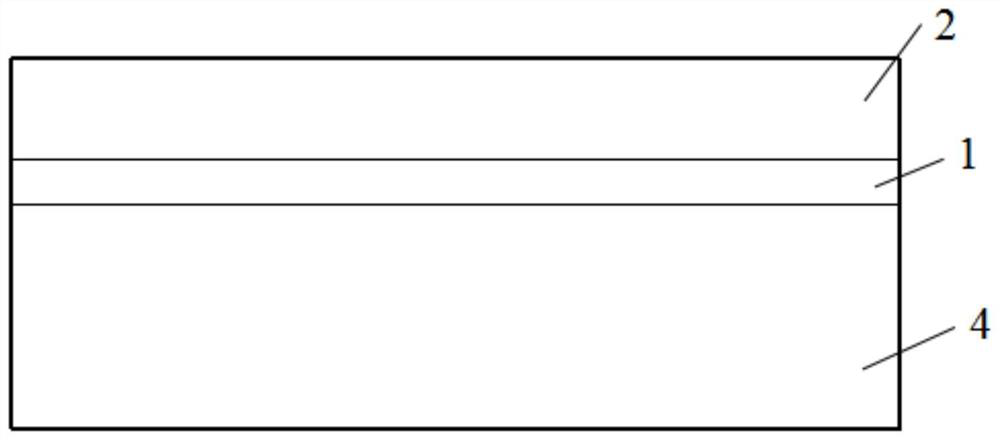

[0055] (a), coating the raw material mixture of the first coating 1 on the surface of the substrate 3, and after drying, obtain the first coating 1 by induction brazing;

[0056] (b), coating the raw material mixture of the second coating 2 on the surface of the first coating 1, obtaining a single-layer solder coating after induction brazing, and drying the solder coating;

[0057] (c), optionally repeating step (b) until a second coating 2 of desired thickness is obtained.

[0058] In the preparation method of the wear-resistant coating provided by the present invention, the method first mixes the coating raw material and the adhesive to form a paste, coats it on the surface of the substrate 3, and then adopts the induction brazing method to prepare the coating. The preparation method It has the advantages of low cost, fast heating rate, small heat-affec...

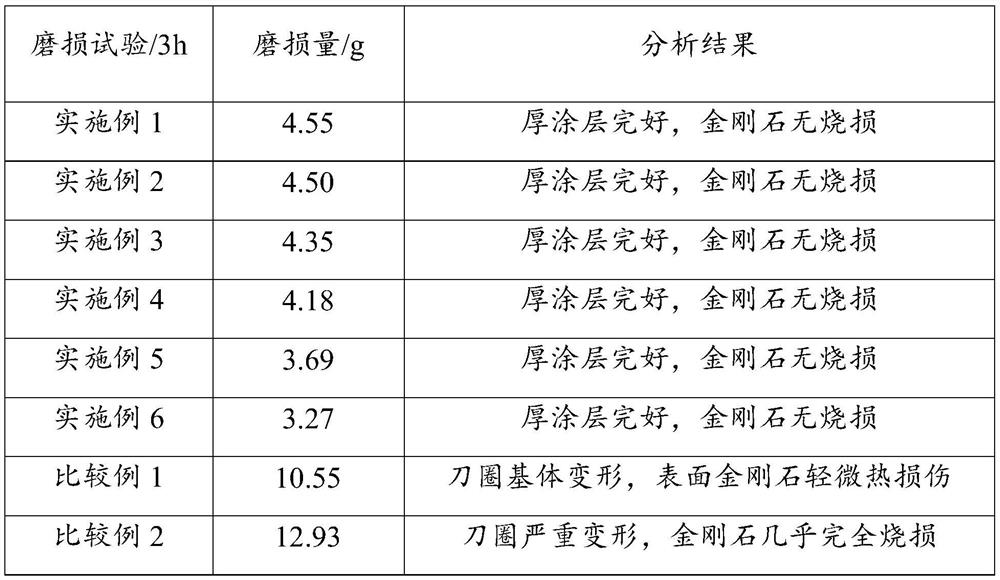

Embodiment 1

[0075] The wear-resistant coating provided in this embodiment is prepared from the following raw materials and methods:

[0076] combine figure 1 As shown, the wear-resistant coating is composed of multiple, different, and thinner coatings. The hard phase in the coating is diamond powder, and the total thickness of the coating is controlled to be 5-6mm;

[0077] The raw material of the first coating 1 is 100% Inconel718 alloy powder, and the particle size ranges are 200-280 mesh respectively;

[0078] The raw materials of the second coating 2 are 5 parts of diamond micropowder (with a particle size range of 50-150 mesh), 1 part of calcium fluoride, and 94 parts of Ni60 alloy powder (with a particle size range of 200-300 mesh).

[0079] Concrete preparation method comprises the following steps:

[0080] (a) Coating the mixture of Nichrome powder and binder on the surface of the substrate 3 with a thickness of 0.3mm, drying at 110°C for 0.5h, and obtaining the first coating 1...

Embodiment 2

[0084] The wear-resistant coating provided in this embodiment is prepared from the following raw materials and methods:

[0085] combine figure 1 As shown, the wear-resistant coating is composed of multiple, different, and thinner coatings. The hard phase in the coating is diamond powder, and the total thickness of the coating is controlled to be 5-6mm;

[0086] The raw material of the first coating 1 is 100% Inconel718 alloy powder, and the particle size ranges are 200-280 mesh respectively;

[0087] The raw materials of the second coating 2 are 6 parts of diamond micropowder (with a particle size range of 50-150 mesh), 2 parts of calcium fluoride, and 92 parts of Ni60 alloy powder (with a particle size range of 200-300 mesh).

[0088] Concrete preparation method comprises the following steps:

[0089] (a) Coating the mixture of nichrome powder and binder on the surface of the substrate 3 with a thickness of 0.5 mm, drying at 120° C. for 1 hour, and heating with an ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com