Nested 3D Trench Electrode Silicon Detector

A trench electrode, nested technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of inconvenient adjustment of the detector unit structure, limited sensitivity, limited practicability, etc., and achieve particle absorption performance. and sensitivity enhancement, reduction of dead zone area, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

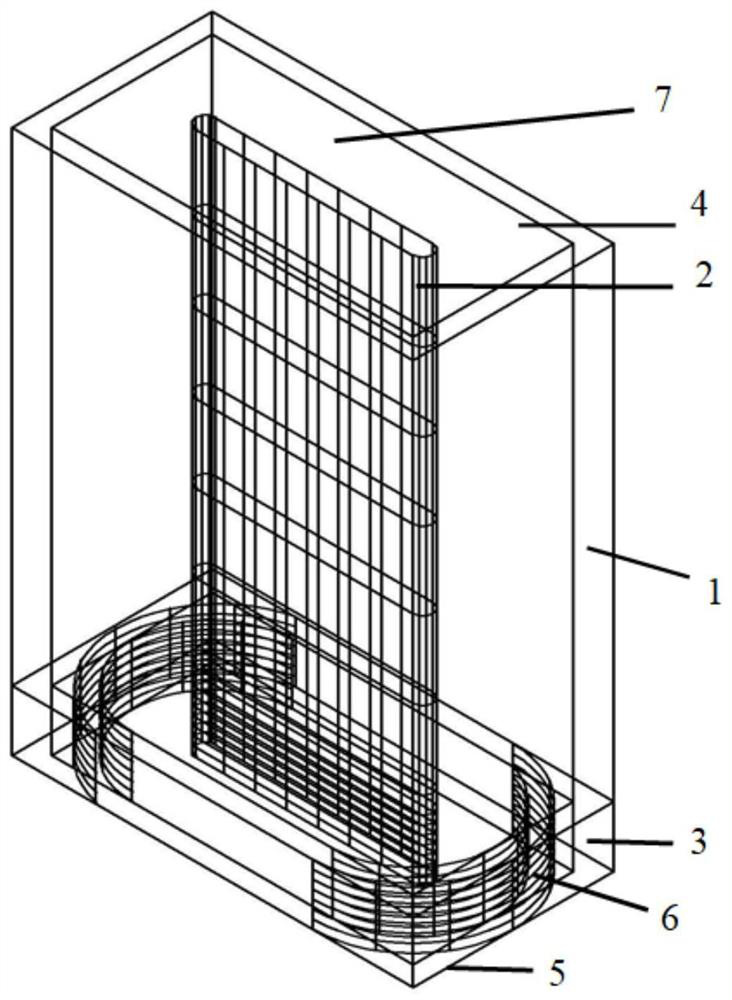

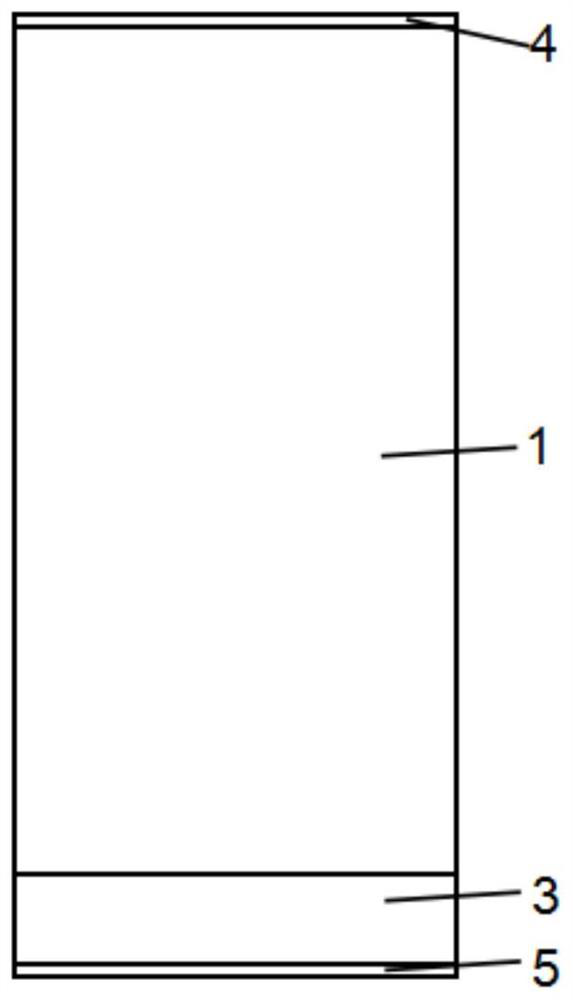

[0025] Nested 3D trench electrode silicon detectors, such as Figure 2~4 As shown, the bottom layer is a silicon dioxide protective layer 5, and the thickness of the silicon dioxide protective layer 5 is 1 μm; a peripheral electrode 1 is arranged on the silicon dioxide protective layer 5, and a height of 30 μm is embedded in the peripheral electrode 1. The nested part 3, the nested part 3 is composed of a p-type silicon substrate 6 located on the upper surface of the silicon dioxide protective layer 5 and an n-type heavily doped phosphorus silicon layer and a p-type lightly doped boron layer located on the upper surface of the p-type silicon substrate 6 Silicon layer; the height of the p-type silicon substrate 6 is 10 μm, the length and width of the p-type silicon substrate 6 are equal to the outer length and outer width of the peripheral electrode 1, the n-type heavily doped phosphorus silicon layer and the p-type lightly doped borosilicate layer The height is 20 μm; the nest...

Embodiment 2

[0027] Nested 3D trench electrode silicon detectors, such as Figure 2~4As shown, the bottom layer is a silicon dioxide protective layer 5, and the thickness of the silicon dioxide protective layer 5 is 1 μm; a peripheral electrode 1 is arranged on the silicon dioxide protective layer 5, and a height of 30 μm is embedded in the peripheral electrode 1. The nested part 3, the nested part 3 is composed of a p-type silicon substrate 6 located on the upper surface of the silicon dioxide protective layer 5 and an n-type heavily doped phosphorus silicon layer and a p-type lightly doped boron layer located on the upper surface of the p-type silicon substrate 6 Silicon layer; the height of the p-type silicon substrate 6 is 20 μm, the length and width of the p-type silicon substrate 6 are equal to the outer length and outer width of the peripheral electrode 1, the n-type heavily doped phosphorus silicon layer and the p-type lightly doped borosilicate layer The height is 10 μm; the nesti...

Embodiment 3

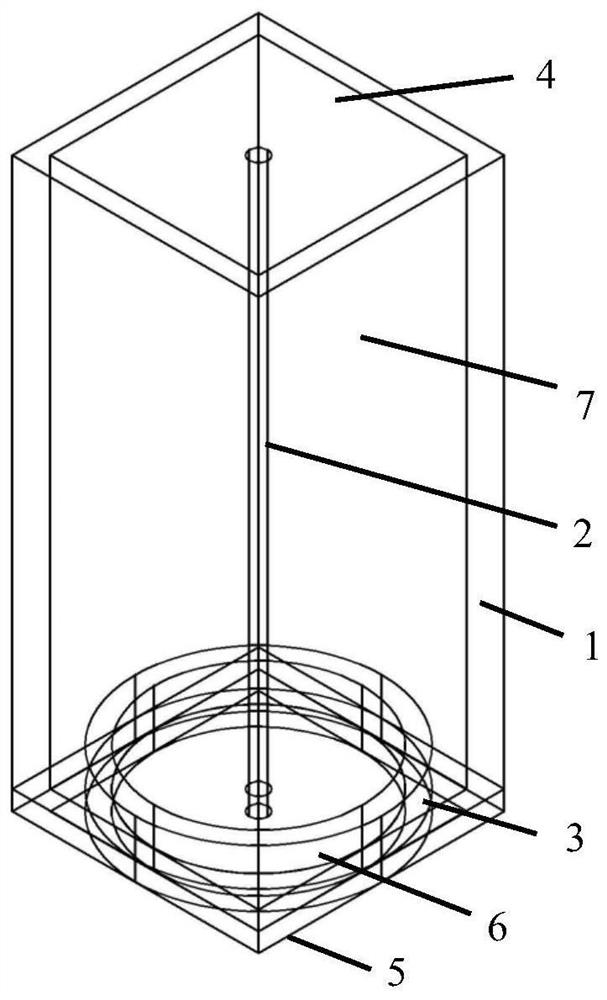

[0029] Nested 3D trench electrode silicon detectors, such as figure 1 As shown, the bottom layer is a silicon dioxide protective layer 5, and the thickness of the silicon dioxide protective layer 5 is 1 μm; on the silicon dioxide protective layer 5, a hollow cylinder nesting part 3 with equal length and a rectangular parallelepiped peripheral electrode are arranged. 1; the nested part 3 is composed of a p-type silicon substrate 6 located on the silicon dioxide protective layer 5 and an n-type heavily doped phosphorus silicon layer and a p-type lightly doped borosilicate layer located on the p-type silicon substrate 6; The height of the sleeve part 3 is 30 μm, the height of the p-type silicon substrate 6 is 25 μm, the length and width of the p-type silicon substrate 6 are equal to the outer length and outer width of the peripheral electrode 1, and the n-type heavily doped phosphorus silicon layer and the p-type lightly doped The height of the borosilicate layer is 5 μm; the cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com