Method for preparing graphene composite coating

A composite material, graphene technology, applied in coatings, electrolytic coatings, etc., can solve the problems of water-based electroplating pollution development and limitation, and achieve the effects of good electrical conductivity, uniform dispersion, easy dissolution and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Choline chloride and ethylene glycol with a molar ratio of 1:1 are selected as the ionic liquid; the ionic liquid contains graphene oxide, and the concentration of graphene oxide is 0.2g / L; the ionic liquid contains copper ions, copper ions The concentration is 1mM.

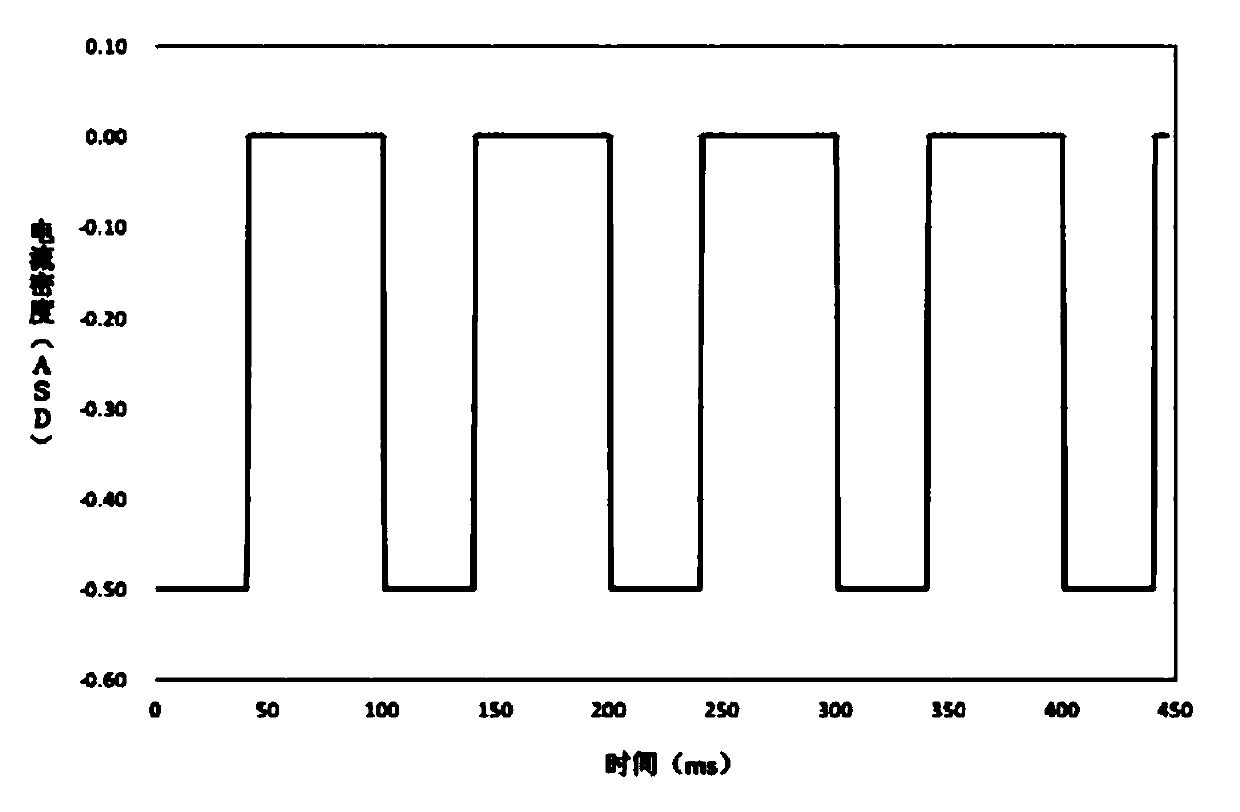

[0045] The above-mentioned ionic liquid is used as the electroplating solution, the copper sheet is selected as the cathode substrate, and the platinum sheet is selected as the anode. A power supply that can provide pulses is used to apply current-controlled pulses. The duration of the positive pulse period is 40ms, and the current density is -0.5ASD, and the duration of the pause period is 60ms. The ionic liquid was stirred without a stirrer during plating.

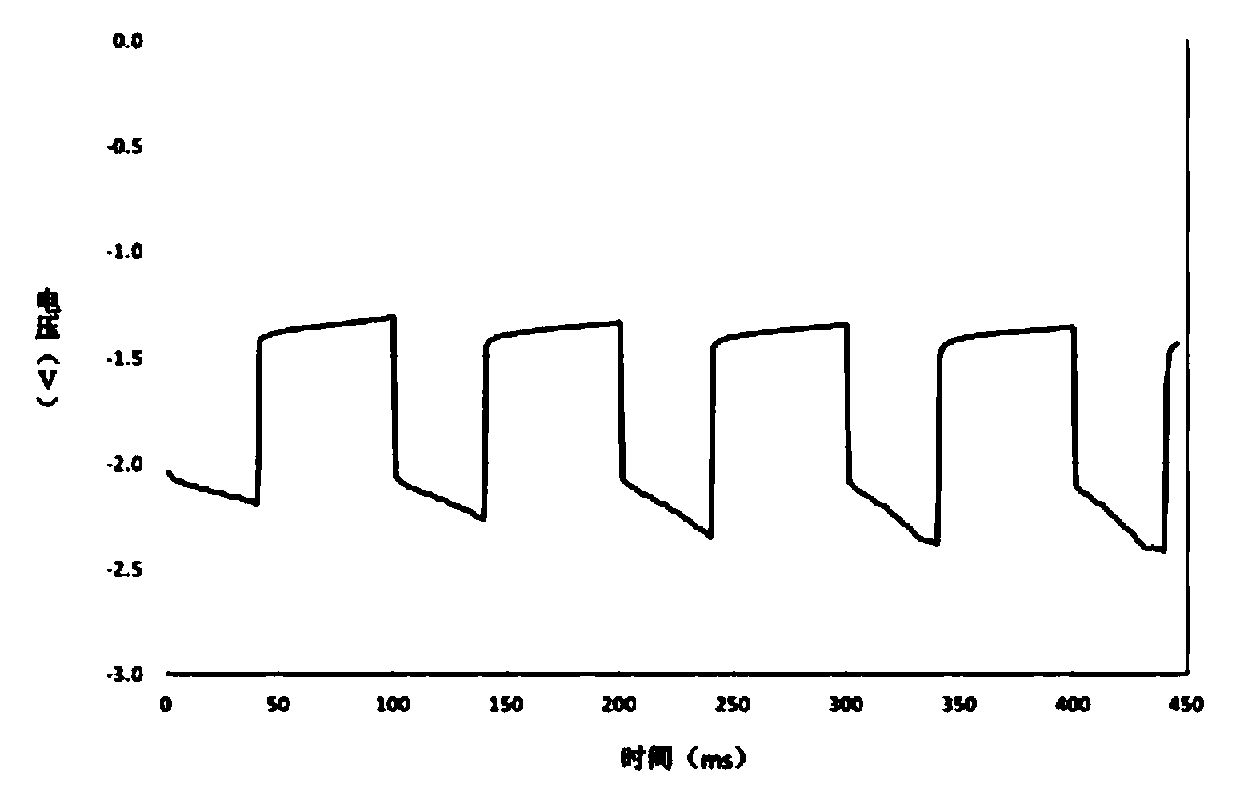

[0046] During pulse plating, current density and corresponding voltage changes, see figure 1 and figure 2 shown. The Raman spectrogram of the graphene composite material coating prepared in this embodiment, please refer to Figure 7 shown.

Embodiment 2

[0048] Choline chloride and ethylene glycol with a molar ratio of 1:2 are selected as the ionic liquid; the ionic liquid contains graphene oxide, and the concentration of graphene oxide is 0.4g / L; the ionic liquid contains copper ions, copper ions The concentration is 10mM.

[0049] The above-mentioned ionic liquid is used as the electroplating solution, the copper sheet is selected as the cathode substrate, and the platinum sheet is selected as the anode. A power supply that can provide pulses is used to apply current-controlled pulses. The duration of the positive pulse period is 40ms, and the current density is -0.75ASD, and the duration of the pause period is 60ms. During electroplating, a stirrer was used to stir the ionic liquid, and the stirring speed was 50 r / min.

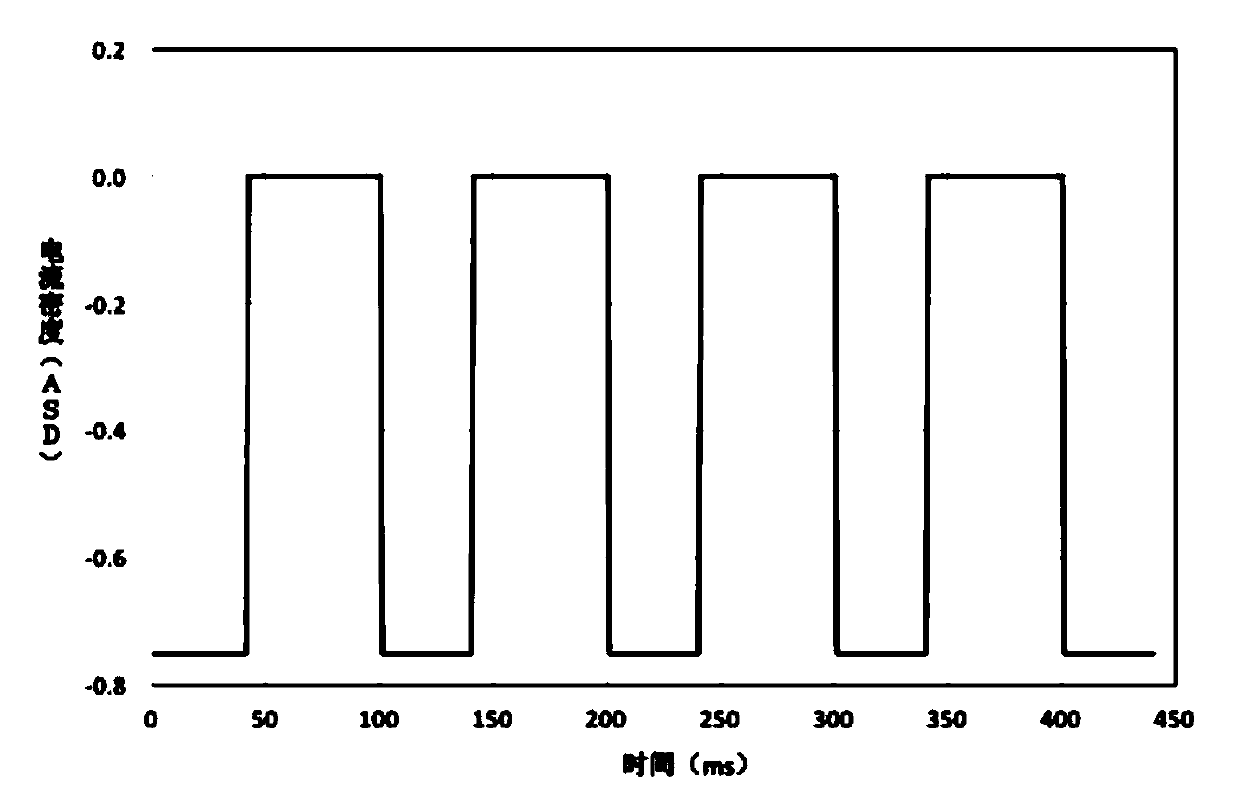

[0050] During pulse plating, current density and corresponding voltage changes, see image 3 and Figure 4 shown. The Raman spectrogram of the graphene composite material coating prepared in this embodi...

Embodiment 3

[0052] Choline chloride and ethylene glycol with a molar ratio of 1:2 are selected as the ionic liquid; the ionic liquid contains graphene oxide, and the concentration of graphene oxide is 0.6g / L; the ionic liquid contains copper ions, copper ions The concentration is 20mM.

[0053] The above-mentioned ionic liquid is used as the electroplating solution, the copper sheet is selected as the cathode substrate, and the platinum sheet is selected as the anode. A power supply that can provide pulses is used to apply current-controlled pulses. The duration of the positive pulse period is 40ms, and the current density is -0.75ASD, and the duration of the pause period is 60ms. During electroplating, a stirrer was used to stir the ionic liquid, and the stirring speed was 50 r / min.

[0054] During pulse plating, current density and corresponding voltage changes, see image 3 and Figure 4 shown. The Raman spectrogram of the graphene composite material coating prepared in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com