A kind of black silicon/(gan) 1-x (zno) x Nanorod composite photoanode and preparation method thereof

A technology of nanorods and composite light, which is applied in chemical instruments and methods, electrodes, chemical/physical processes, etc., can solve the problems of high nitriding reaction temperature, small x value, narrow range, etc., and achieve short nitriding time, x The effect of large value and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

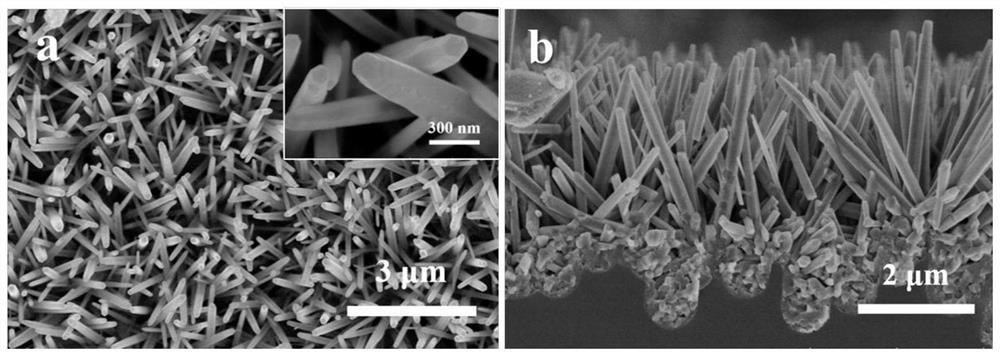

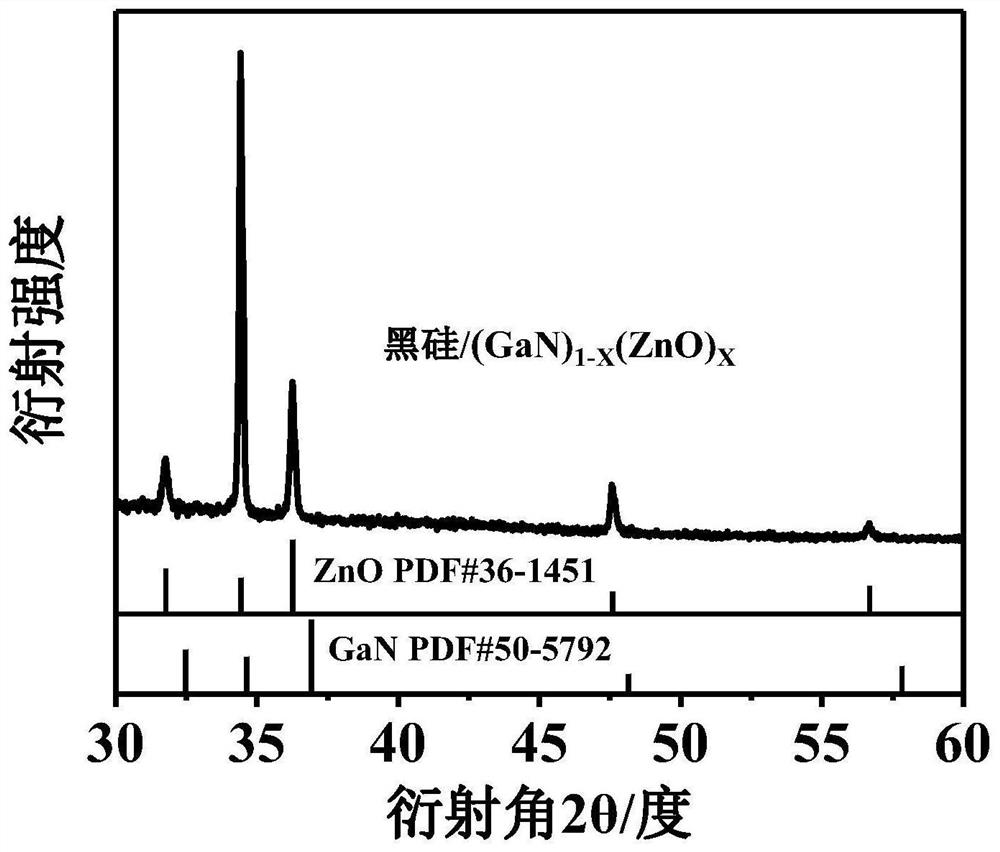

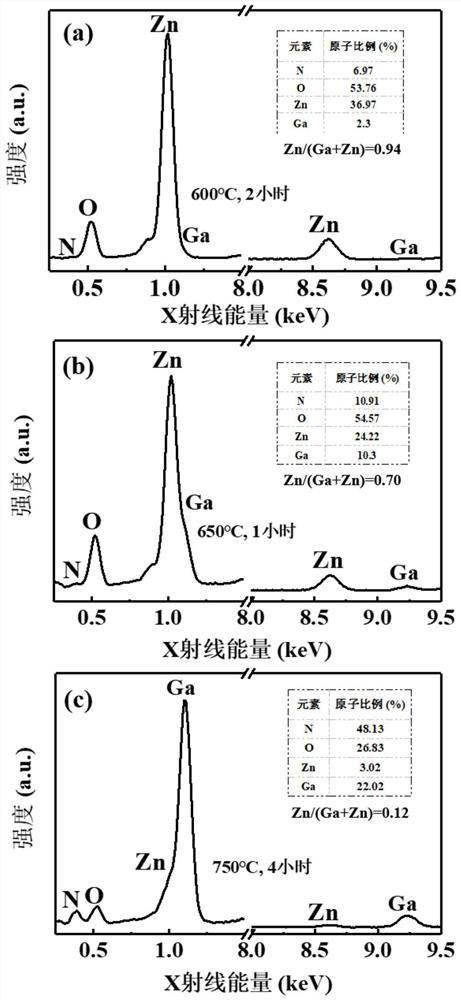

[0039] (1) Ultrasonic wash the black silicon substrate in acetone, ethanol, and deionized water for 20 minutes, then prepare a 0.05mol / L potassium permanganate solution, and put the cleaned black silicon vertically into the potassium permanganate solution for soaking After 30 minutes, wash with water and dry. Add 1.3387g of zinc nitrate hexahydrate to 90ml of water to form a uniform solution of 0.05mol / L, then add 5ml of ammonia water and 5ml of ethanolamine and stir to form a mixed uniform solution. Put the cleaned black silicon vertically into the above mixed solution, react in a water bath at 85°C for 2 hours, wash with water, and dry to obtain black silicon / ZnO nanorods;

[0040] (2) Add 0.60g of zinc nitrate hexahydrate, 0.51g of gallium nitrate hydrate and 0.60g of urea into 100ml of water to prepare a uniformly mixed aqueous solution, then perform a hydrothermal reaction at 150°C for 15h, centrifugally wash, and dry in an oven at 50°C for 20h get ZnGa 2 o 4 powder. ...

Embodiment 2

[0047] (1) Ultrasonic wash the black silicon substrate in acetone, ethanol, and deionized water for 20 minutes, then prepare a 0.05mol / L potassium permanganate solution, and put the cleaned black silicon vertically into the potassium permanganate solution for soaking After 30 minutes, wash with water and dry. Add 0.8032g of zinc nitrate hexahydrate to 90ml of water to form a uniform solution of 0.03mol / L, then add 5ml of ammonia water and 2.5ml of ethanolamine and stir to form a mixed uniform solution. Put the cleaned black silicon vertically into the above mixed solution, react in a water bath at 95°C for 1 hour, wash with water, and dry to obtain black silicon / ZnO nanorods;

[0048] (2) Add 0.74g of zinc nitrate hexahydrate, 0.64g of gallium nitrate hydrate and 1.20g of urea into 100ml of water to prepare a uniformly mixed aqueous solution, then perform a hydrothermal reaction at 180°C for 12h, centrifugally wash, and dry in an oven at 70°C for 15h get ZnGa 2 o 4 powder. ...

Embodiment 3

[0054] (1) Ultrasonic wash the black silicon substrate in acetone, ethanol, and deionized water for 20 minutes, then prepare a 0.05mol / L potassium permanganate solution, and put the cleaned black silicon vertically into the potassium permanganate solution for soaking After 30 minutes, wash with water and dry. Add 1.8742g of zinc nitrate hexahydrate to 90ml of water to form a uniform solution of 0.07mol / L, then add 5ml of ammonia water and 10ml of ethanolamine and stir to form a mixed uniform solution. Put the cleaned black silicon vertically into the above mixed solution, react in a water bath at 70°C for 5 hours, wash with water, and dry to obtain black silicon / ZnO nanorods;

[0055] (2) Add 0.89g of zinc nitrate hexahydrate, 0.77g of gallium nitrate hydrate and 1.80g of urea into 100ml of water to prepare a uniformly mixed aqueous solution, then perform a hydrothermal reaction at 200°C for 10h, centrifugally wash, and dry in an oven at 90°C for 10h get ZnGa 2 o 4 powder. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com