Graphene/fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation method thereof

A graphene composite and self-crosslinking technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of tedious, time-consuming and material-consuming, etc., and achieve the effect of simple operation method, expanded application range, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]Preparation of graphene composite fluorosilicone self-crosslinking resin of the present invention

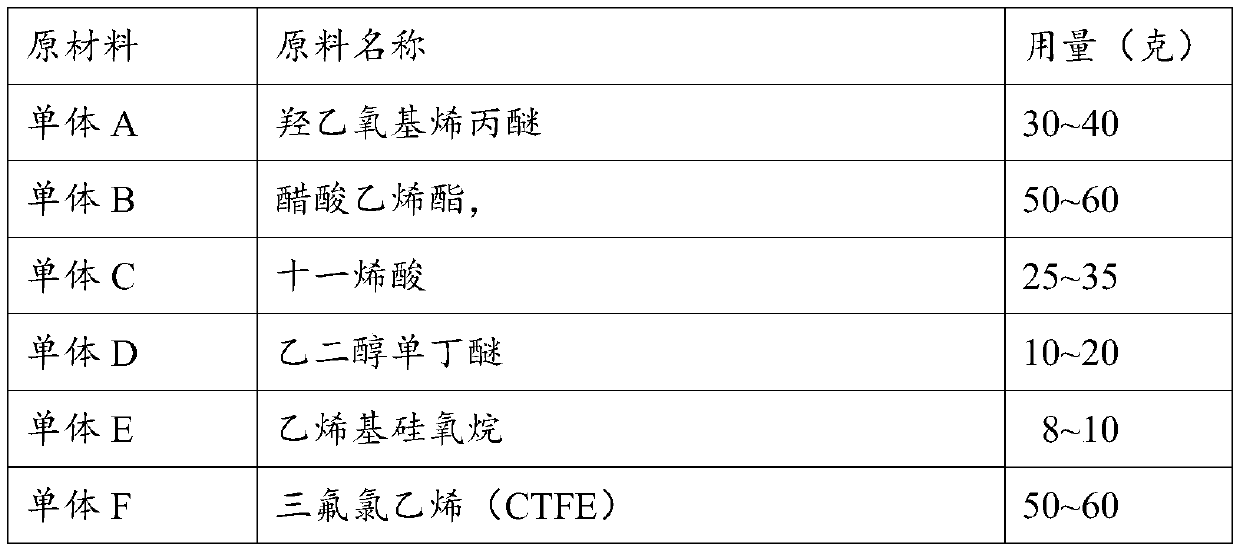

[0033] Table 1. Raw materials and their amounts used in the preparation of graphene composite fluorosilicone self-crosslinking resin

[0034]

[0035]

[0036] The preparation of the resin of the present invention: Add monomers A, B, C, D, E, graphene oxide, solvent and initiator into a 500mL autoclave, stir at high speed for 0.5h-1h, vacuum inhale monomer F, and heat up to 72 ℃ reaction 16h. Add 1-2 grams of initiator and a little solvent, and react for 4 hours. Raise the temperature to 80°C and react for another 4h. Cool down to room temperature, and filter out the material.

[0037] Table 2 Properties of graphene composite fluorosilicone self-crosslinking resin

[0038] Exterior Solid content / % Coating 4-cup viscosity / sec Transparent yellowish, uniform 50.0~53.0 145~310 after dilution 39.0~47.0 70~110

[0039] Preparation of gr...

Embodiment 1

[0044] Embodiment 1. Preparation of graphene composite fluorosilicone self-crosslinking resin

[0045] 35.55 grams of monomer A, 52.45 grams of monomer B, 30.19 grams of monomer C, 14.74 grams of monomer D, 9.00 grams of monomer E, 10 grams of graphene oxide, 125 grams of solvent (40 grams of methyl isobutyl ketone, two Add 55 grams of toluene, 20 grams of solvent naphtha S-150, 10 grams of butyl acetate), 10 grams of graphite oxide, and 5.5 grams of initiator azobisisobutyronitrile into a 500mL autoclave, stir at high speed for half an hour to 40 minutes, and vacuum Inhale 55 grams of monomer F, and raise the temperature to 72°C for 16 hours. Add 1 gram of initiator and react for 4h. Raise the temperature to 80°C and react for another 4h. Cool down to room temperature, and filter out the material. The obtained resin has a solid content of 52% and a coating viscosity of 196 seconds in -4 cups. In order to facilitate the preparation of coatings, it can be diluted to a solid...

Embodiment 2

[0046] Embodiment 2. Preparation of graphene composite fluorosilicone self-crosslinking resin topcoat

[0047] Add 64 grams of resin, 1 gram of BYK161 dispersant, 23 grams of 2310 titanium dioxide, 3 grams of kaolin, 8.3 grams of X-2 thinner, 1.3 grams of BYK306 leveling agent, 0.4 grams of BYK066 defoamer into the paint tank, and stir well Sand and disperse, ready for brushing.

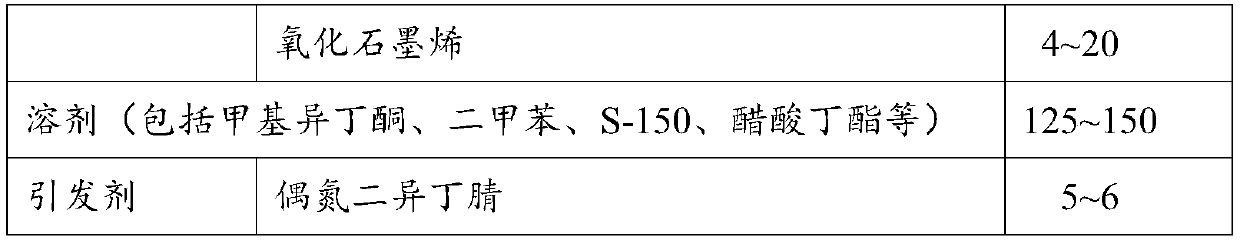

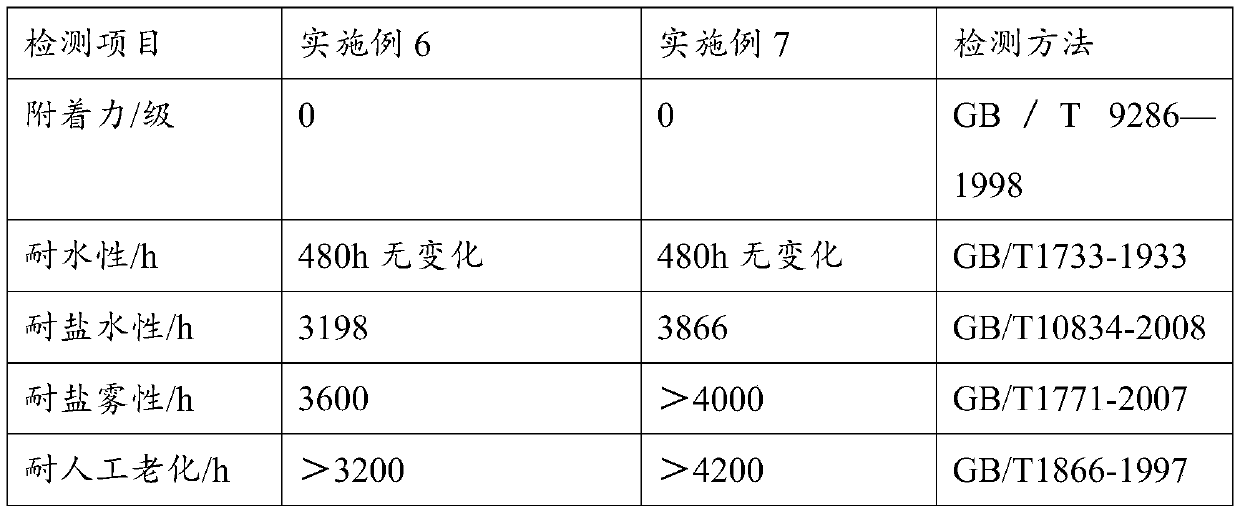

[0048] Embodiment 3~8. operating steps and reaction conditions are the same as embodiment 1 and 2, and coating is just that graphene content is different, and performance sees the following table:

[0049] Table 4. Effect of different amounts of graphene oxide on coating properties

[0050] component name Example 1 Example 3 Example 4 Example 5 Graphene oxide / g 0 4 8 12 Surface resistivity / Ω 10 12

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com