A kind of polymer blend compatibilized by silane carbon quantum dots and its preparation method and application

A silane carbon quantum and polymer technology, which is applied in the field of polymer blends and preparations compatibilized by silane carbon quantum dots. finely structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing silane carbon quantum dots, including:

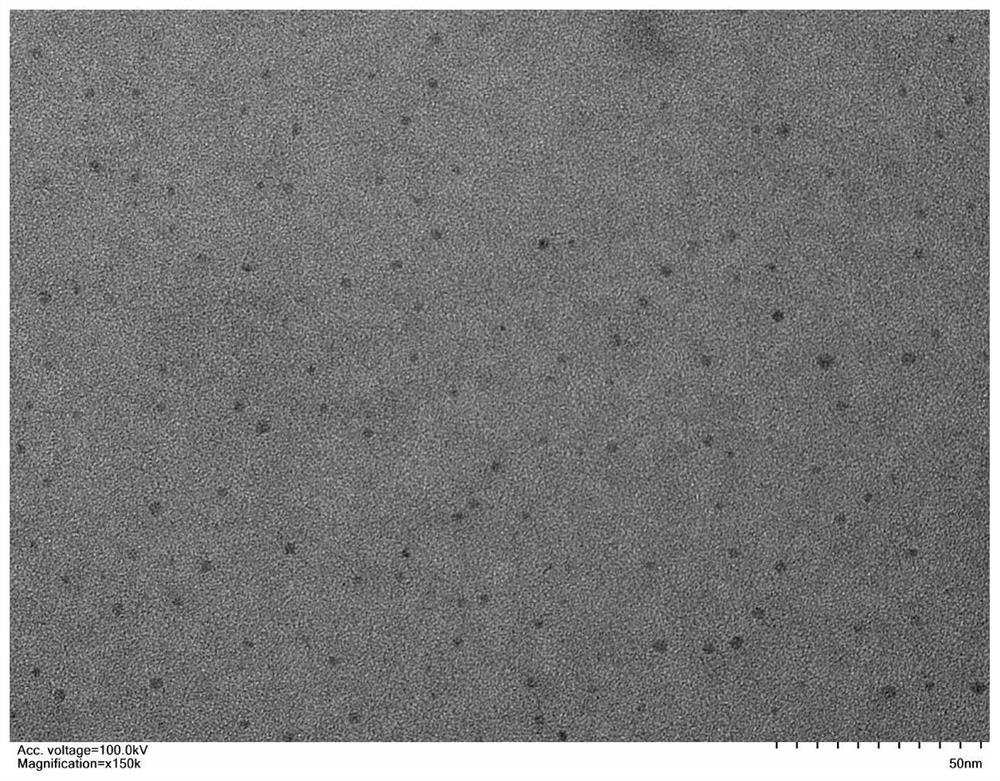

[0039] Weigh citric acid solid powder and silane KH792 according to the dosage in Table 1 into a 100ml polytetrafluoroethylene-lined stainless steel reactor. After tightening the reactor, put it into an electric oven and react at 180° for 6 hours. After the reaction kettle was naturally cooled to room temperature, a bright brown liquid was obtained. Utilize sherwood oil to be extraction liquid, in separating funnel, gained liquid is extracted three times, obtain final carbon point (such as figure 1 shown).

[0040] The dosage ratio of table 1 citric acid and silane KH792

[0041]

[0042]

[0043] The particle size of each carbon quantum dot obtained in this embodiment is 2nm.

Embodiment 2

[0045] This embodiment provides a method for preparing silane carbon quantum dots, including:

[0046] Weigh 0.5g of citric acid solid powder and add it to 10ml of DMF solution, stir until it is fully dissolved, then mix the above solution with 10ml of silane KH792 and add it to a 100ml Teflon-lined stainless steel reactor. After tightening, put it into an electric heating oven and react at 180° for 6h. After the reaction kettle was naturally cooled to room temperature, a bright brown liquid was obtained. Using petroleum ether as the extraction liquid, the resulting liquid was extracted three times in a separating funnel to obtain the final carbon dots (silane carbon quantum dots V).

[0047] The carbon quantum dots prepared in this example have a size of 5 nm.

Embodiment 3

[0049] The present embodiment provides a kind of preparation method of polymer copolymer, comprising:

[0050] The basic composition and mass parts of raw materials are as follows:

[0051]

[0052] Specific steps are as follows:

[0053] First, mix methyl vinyl silicone rubber with silane carbon quantum dot II to obtain a composite material; then mix polypropylene and silicone rubber / carbon quantum dot composite material at 170°C to 260°C, and add an antioxidant in proportion, After uniform mixing, the material is cooled to room temperature to obtain a carbon dot compatibilized polypropylene / silicone rubber blend.

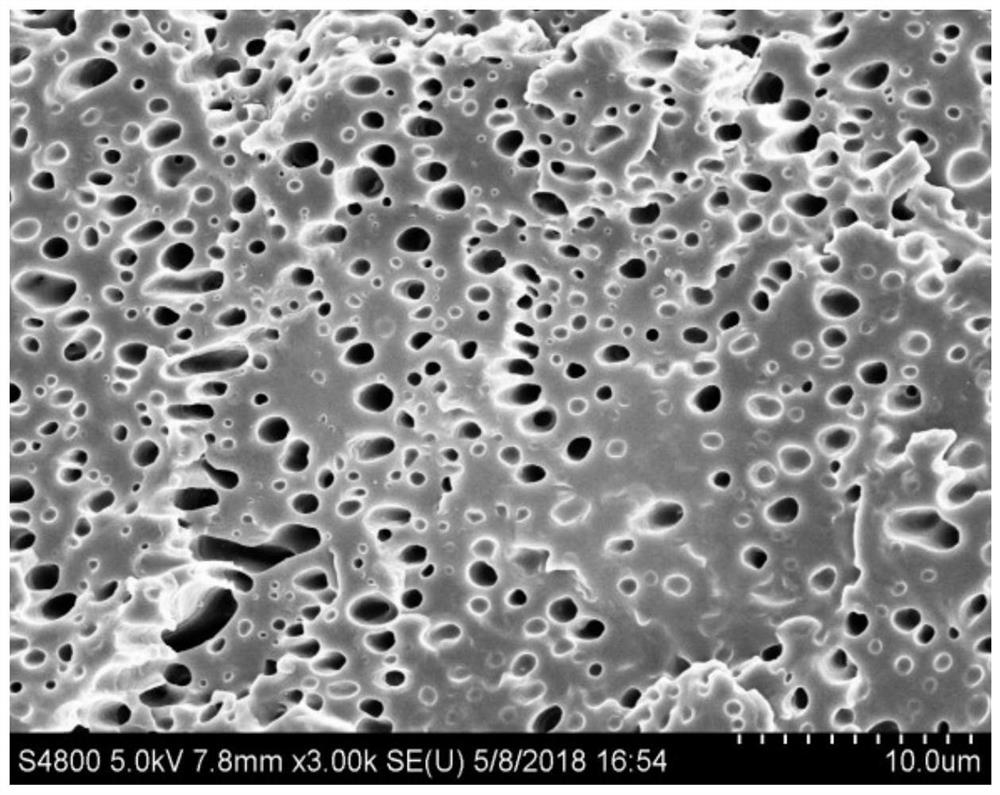

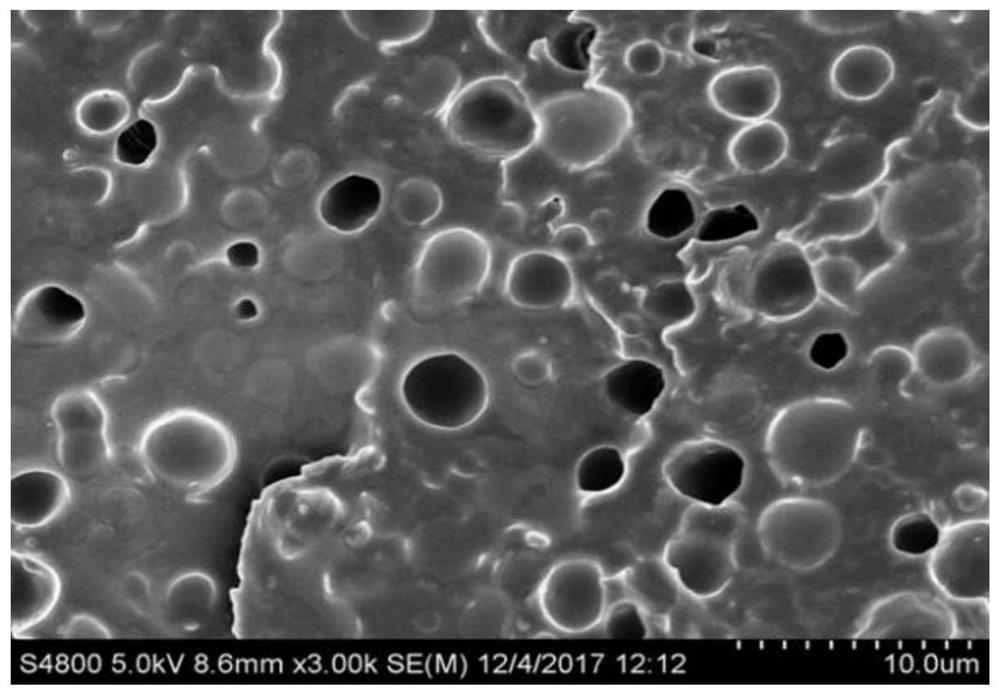

[0054] The blended polymer prepared in this example was characterized by scanning electron microscopy of the brittle fracture surface to observe the effect of carbon quantum dots on the compatibility of silicone rubber and polyurethane. as table 2 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com