Method for preparing multifunctional durable and self-repairing superhydrophobic fabric surface

A durable and super-hydrophobic technology, applied in the field of materials, can solve the problems of environmental and human health hazards, restrictions on wide application, rough structure damage, etc., and achieve the effect of low price, good controllability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

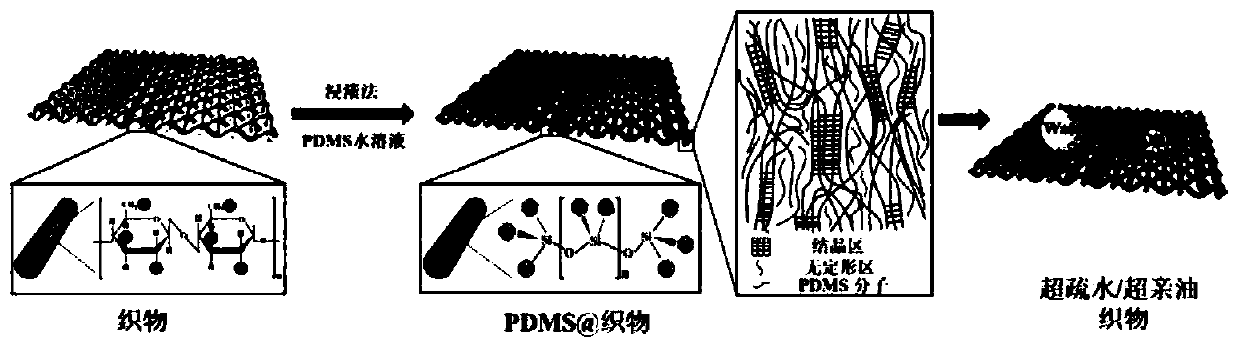

[0055] The present invention also provides a method for preparing the surface of a multifunctional durable and self-repairing superhydrophobic fabric, specifically comprising the following steps:

[0056] (1) Preparation of polydimethylsiloxane aqueous solution: first carry out plasma treatment on polydimethylsiloxane in air, then pour polydimethylsiloxane into deionized water, and ultrasonically make it Evenly dispersed;

[0057] (2) Preparation of multifunctional durability and self-repairing superhydrophobic fabric: first place the fabric in acetone and absolute ethanol solutions, ultrasonically remove the wax and impurities on the surface, take it out and dry it after a period of time; then place the fabric Put it into the aqueous solution of polydimethylsiloxane, take it out and dry it after a period of time;

[0058] (3) The multifunctional durability and self-healing superhydrophobic fabrics are tested for wear resistance, washing and chemical stability in harsh enviro...

Embodiment 1

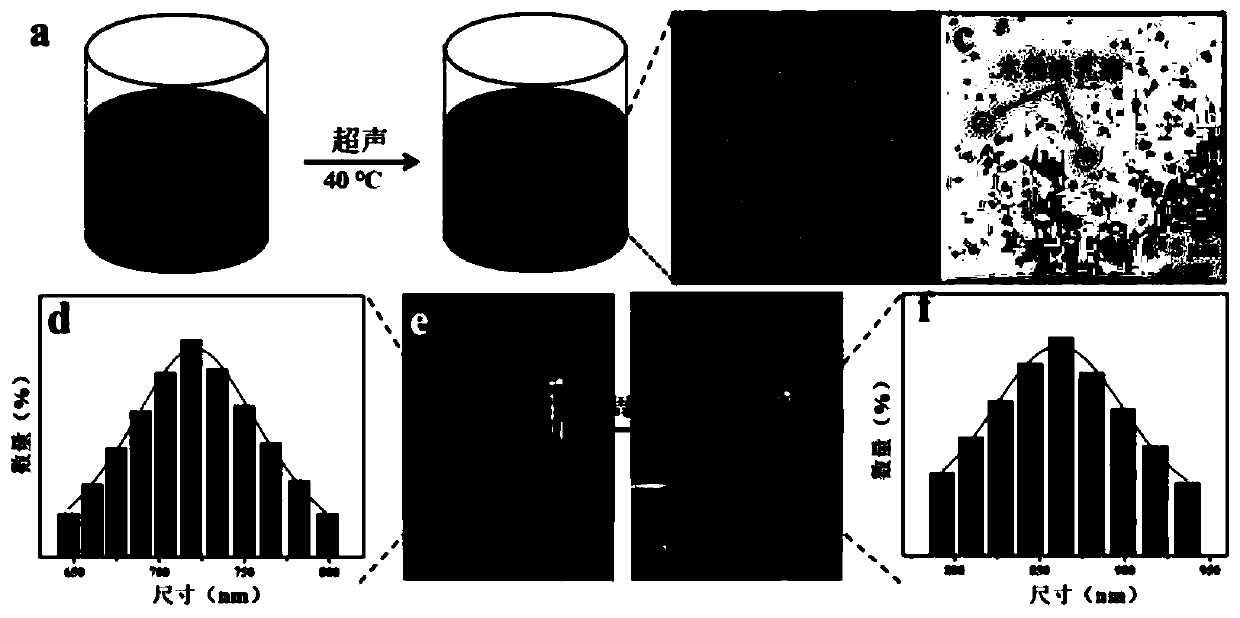

[0070] Firstly, polydimethylsiloxane (PDMS) was subjected to plasma treatment in the air, and the plasma treatment power was 500W. After 10 minutes of treatment, the PDMS was poured into deionized water. The concentration of PDMS was 0.9wt%, and 40°C was ultrasonicated for 60 minutes. , to disperse evenly in water;

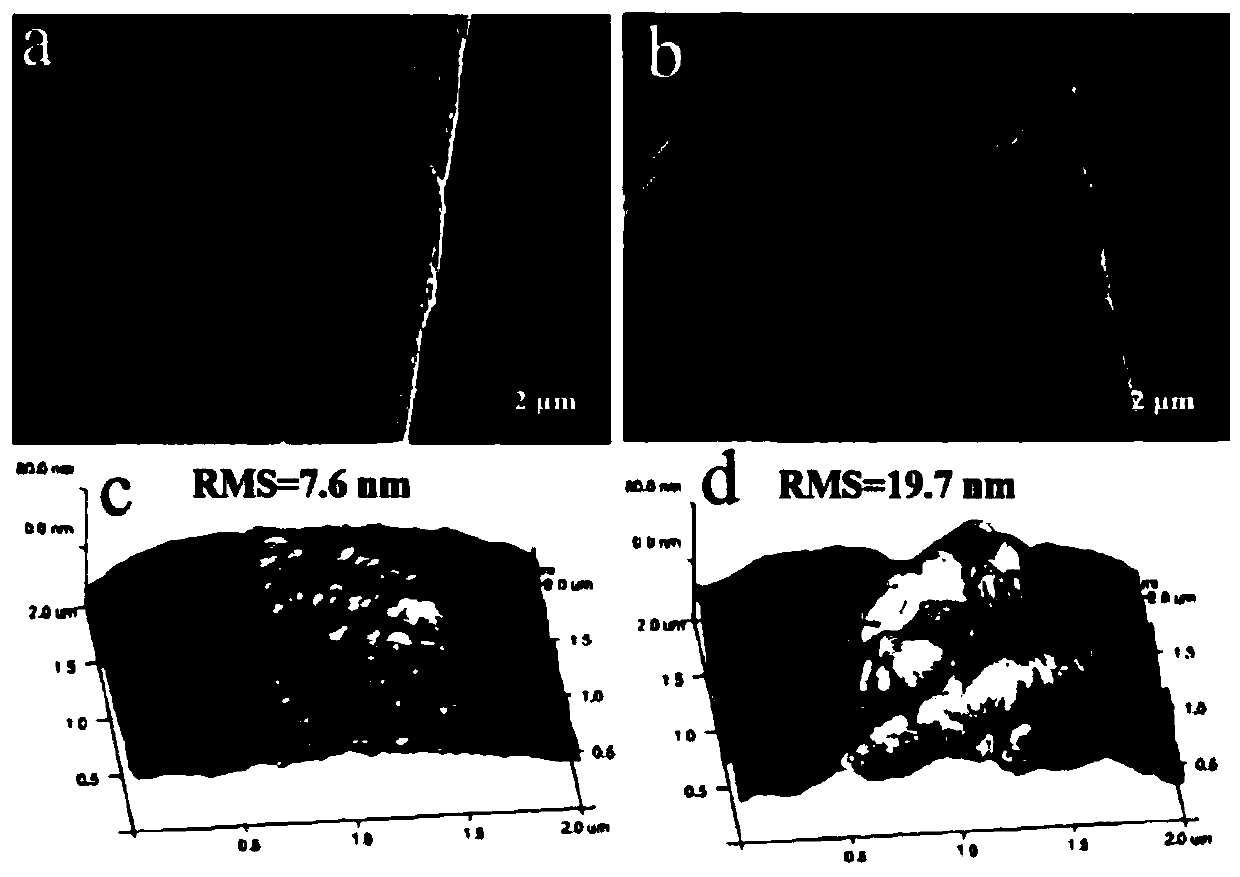

[0071] The obtained PDMS aqueous solution is detected, and the results are shown in figure 2 and image 3 , figure 2 Optical photographs of the aqueous solution and PDMS aqueous solution prepared for Example 1 of the present invention, from figure 2 It can be seen in a that the deionized water is a transparent clear liquid, while the PDMS aqueous solution is an emulsion ( figure 2 b), the PDMS aqueous solution has no stratification, indicating that it is uniformly dispersed in the aqueous solution. Additionally, from image 3 It can be seen from a-c that the ultrasonic wave makes PDMS evenly dispersed in the aqueous solution, the hydroxyl groups at the en...

Embodiment 2

[0093] The PDMS is firstly treated with plasma in the air. The plasma treatment power is 800W. After 5 minutes of treatment, the PDMS is poured into deionized water. The concentration of PDMS is 0.3wt%, and 30°C is ultrasonicated for 30 minutes to make it uniformly dispersed in water.

[0094] First cut the hemp fabric into 2*2cm squares, place them in acetone and absolute ethanol solutions for ultrasonic cleaning, take them out after 50 minutes, place them in an oven at 70°C for 8 hours, and then weigh a certain amount of polydimethylsiloxane Finishing solution, make the mass ratio of polydimethylsiloxane finishing solution and hemp fabric to be 1:1, put the hemp fabric into the prepared polydimethylsiloxane finishing solution, take it out after soaking for 2min, and put it in an oven Place at 90°C for 13h.

[0095] The multi-functional durability and intelligent self-repairing superhydrophobic hemp fabric surface that embodiment 2 prepares is analyzed, and its contact angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com