Non-noble metal electrocatalyst based on melaleuca leucadendron bark powder and preparation method and application thereof

A non-precious metal, electrocatalyst technology, used in circuits, electrical components, battery electrodes, etc., can solve the problems of small resources, unstable iron-nitrogen carbon-based ORR electrocatalysts, and high prices, and achieve easy preparation, excellent oxygen reduction. Catalytic activity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

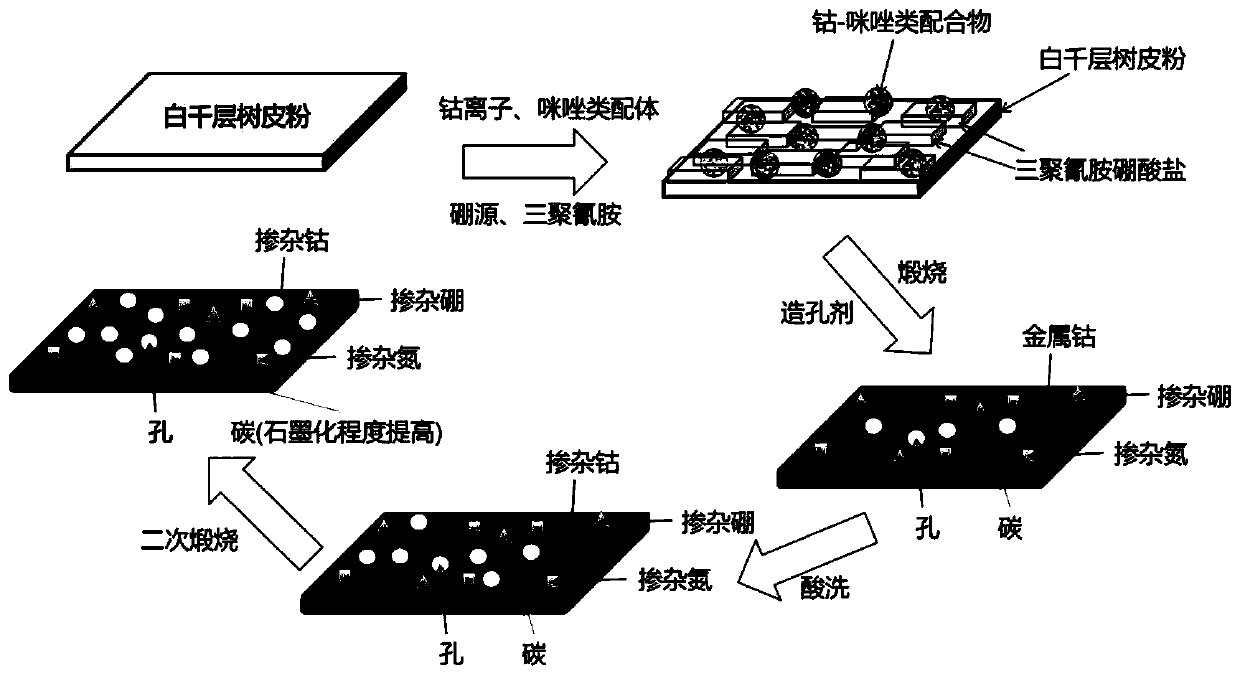

[0074] This embodiment provides a non-precious metal electrocatalyst based on Melaleuca bark powder, which is prepared through the following process.

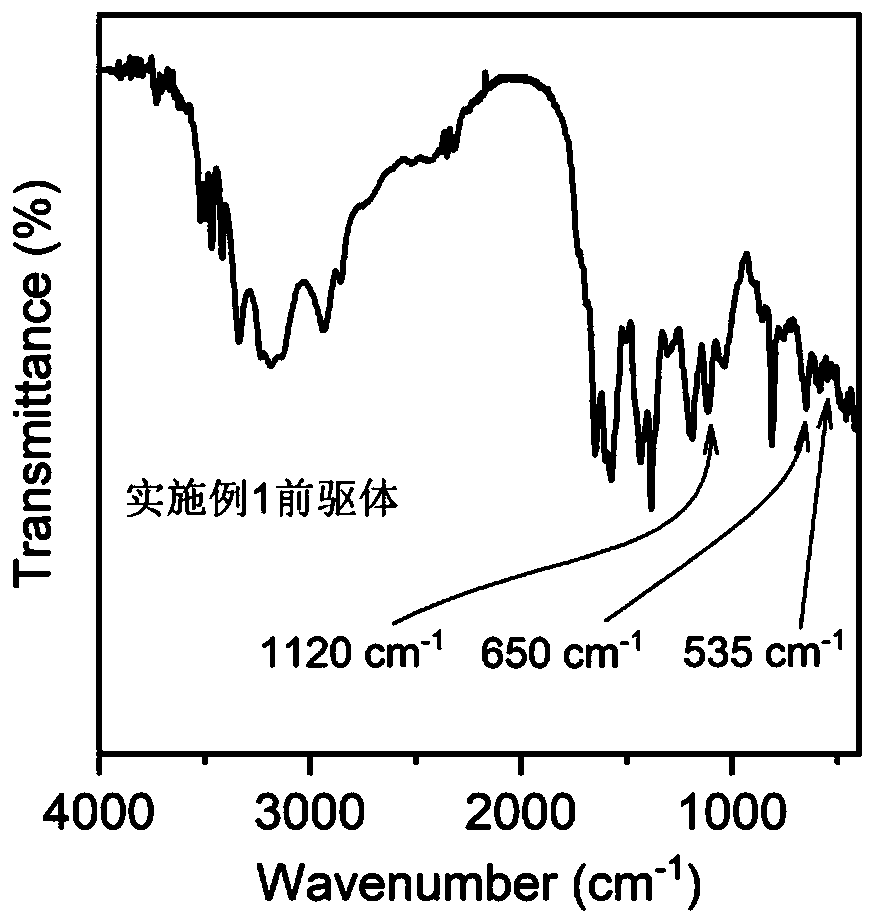

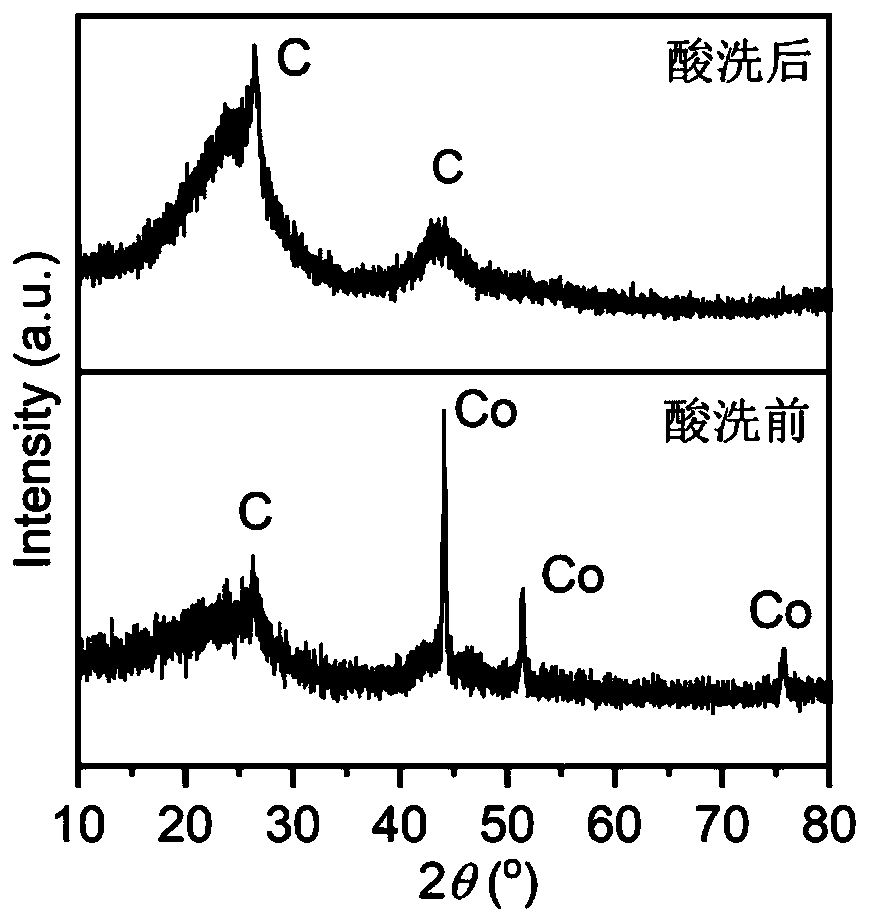

[0075] Add 2-methylimidazole (1.54g), boric acid (1.16g), and melamine (2.363g) into a small amount of ethanol and sonicate for 10 minutes to form a suspension; mix and grind Melaleuca bark powder (3g) with the suspension After 30 minutes, the ground slurry was mixed with cobalt nitrate hexahydrate (0.727 g) and ultrasonically mixed for 30 minutes, then stirred, evaporated to dryness and dried. The product obtained by drying (referred to as the precursor) and the pore-forming agent ZnCl 2 Put it into a mortar and grind it evenly according to the mass ratio of 1:4. The resulting mixture was heated in a tube furnace under the protection of argon at a rate of 2 °C / min to 900 °C for 2 h and then cooled naturally. The product obtained after calcination (denoted as after calcination or before pickling) was treated with 0.5mol / L H ...

Embodiment 2

[0078] This embodiment provides a non-precious metal electrocatalyst based on Melaleuca bark powder, which is prepared through the following process.

[0079] Add 2-methylimidazole (1.54g), boric acid (1.16g), and melamine (2.363g) into a small amount of ethanol and sonicate for 10 minutes to form a suspension; mix and grind Melaleuca bark powder (3g) with the suspension After 30 minutes, the ground slurry was mixed with cobalt nitrate hexahydrate (1.091 g) and ultrasonically stirred for 30 minutes, then evaporated to dryness with stirring and dried. The product obtained by drying and the pore forming agent ZnCl 2 Put it into a mortar and grind it evenly according to the mass ratio of 1:4. The resulting mixture was heated in a tube furnace under the protection of argon at a rate of 2 °C / min to 900 °C for 2 h and then cooled naturally. The product obtained after calcination was treated with 0.5mol / L H 2 SO 4 Acid washing for 4 hours, washing to remove the acid and drying to...

Embodiment 3

[0082] This embodiment provides a non-precious metal electrocatalyst based on Melaleuca bark powder, which is prepared through the following process.

[0083] Add 2-methylimidazole (1.54g), boric acid (1.16g), and melamine (2.363g) into a small amount of ethanol and sonicate for 10 minutes to form a suspension; mix and grind Melaleuca bark powder (3g) with the suspension After 30 minutes, the ground slurry was mixed with cobalt nitrate hexahydrate (1.454 g) and ultrasonically stirred for 30 minutes, then evaporated to dryness with stirring and dried. The product obtained by drying and the pore forming agent ZnCl 2 Put it into a mortar and grind it evenly according to the mass ratio of 1:4. The resulting mixture was heated in a tube furnace under the protection of argon at a rate of 2 °C / min to 900 °C for 2 h and then cooled naturally. The product obtained after calcination was treated with 0.5mol / L H 2 SO 4 Acid washing for 4 hours, washing to remove the acid and drying to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com