Method for preparing biochar and hydrogen by utilizing anaerobic fermentation by-products

A technology of anaerobic fermentation and anaerobic fermentation tank, which is applied in the field of preparing biochar and hydrogen by the by-products of anaerobic fermentation, which can solve the problems of difficult industrial production and application, high requirements for process conditions, and high production costs, and achieve a well-developed pore structure, Enhance the mass transfer and heat transfer process, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

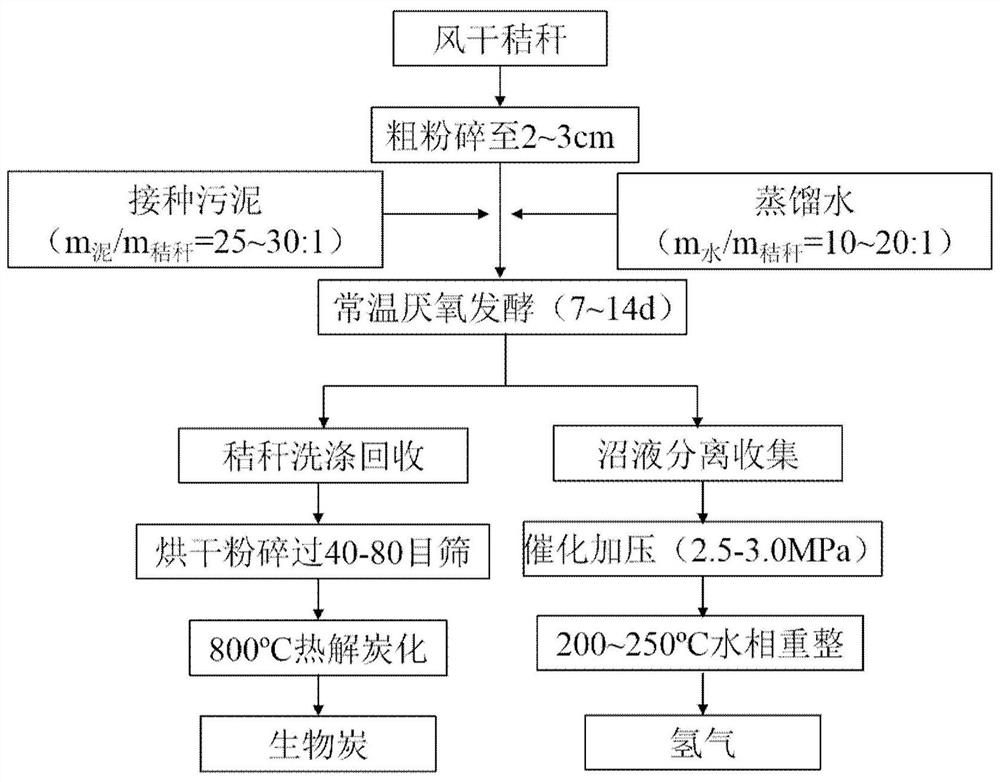

[0088] A method for preparing biochar and hydrogen by using anaerobic fermentation by-products, using such as figure 1 The process flow shown.

[0089] 1) Coarse crushing of straw: take 500g of natural air-dried corn stalks for coarse crushing, and take straws with a length of about 2cm for use;

[0090] 2) Anaerobic fermentation treatment: take 15kg of inoculation mud (the mass ratio of inoculation mud to straw is 30:1) and mix it with coarsely crushed straw and pour it into the fermenter, pour 10kg of distilled water (the mass ratio of distilled water to straw is 20:1), Stir the mixed materials evenly, submerge the nitrogen pipe into the bottom of the fermenter, and purge for 3 minutes to ensure an anaerobic environment. Leave a biogas outlet on the top of the fermenter, and submerge the gas outlet pipe into the water to prevent air from entering the fermenter. Place the fermenter in an environment of 25°C for 14 days, and stir the fermentation material every 12 hours to pr...

Embodiment 2

[0099] The same raw material and method of the used embodiment 1 of present embodiment, but biogas slurry hydrogen production nickel-based catalyst carrier is CeO 2 . The test data of the specific surface area of the biochar by-product of anaerobic fermentation biogas residues are shown in Table 1, and the components and contents of hydrogen production gas products from biogas slurry are shown in Table 2.

Embodiment 3

[0101] The same raw materials and methods as in Example 1 are used in this example, but the dosage of biogas slurry hydrogen production catalyst is 0.5g, and the temperature of the reactor is raised to 200°C. See Table 1 for the specific surface area test data of biochar by-product biogas residue from anaerobic fermentation, and see Table 2 for the components and contents of hydrogen production gas products from biogas slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com