Polylactic acid cigarette tow, preparation method and application of tow

A polylactic acid cigarette, polylactic acid-based technology, applied in the field of polylactic acid, can solve the problems of laborious suction, high suction resistance of the filter, collapse deformation, etc., and achieves not easy to collapse deformation, good heat shrinkage performance, and good deformation resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

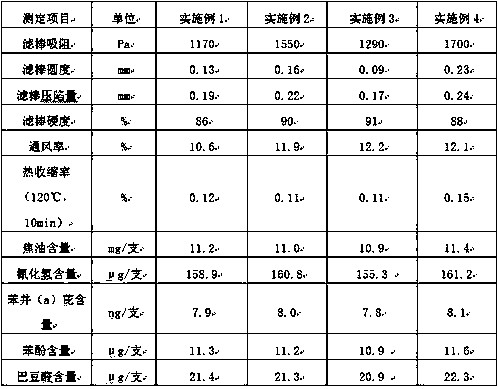

Examples

Embodiment 1

[0054] Embodiment 1 A kind of polylactic acid tobacco tow and its preparation method

[0055] A polylactic acid tow for cigarettes is made of the following raw materials in parts by weight:

[0056] 90 parts of L-lactide;

[0057] 2.5 parts of stannous octoate;

[0058] Polyene thermoplastic PP masterbatch 5 parts;

[0059] Food grade silicone masterbatch 3 parts;

[0060] 0.5 parts of oligolactic acid-β-cyclodextrin;

[0061] 9 parts of food grade sodium carbonate;

[0062] 0.1 part of polyethylene glycol oleate;

[0063] 0.05 parts of hydroxymethyl cellulose;

[0064] 180 parts of deionized water;

[0065] Antistatic oil agent (TAKEMATO OIL&FAT CO.,LTD) 5 parts.

[0066] The L-lactide has an optical purity >99.8%, a melting point of 97°C, and a water content of 0.2%.

[0067] A method for preparing polylactic acid tow for cigarettes, comprising: rinsing, drying, direct melting, melt extrusion, polymerization, extrusion devolatilization, melting, mixing, microwave tr...

Embodiment 2

[0084] Embodiment 2 A kind of polylactic acid tobacco tow

[0085] A polylactic acid tow for cigarettes is made of the following raw materials in parts by weight:

[0086] 100 parts of L-lactide;

[0087] 3 parts of stannous octoate;

[0088] Polyene thermoplastic PP masterbatch 8 parts;

[0089] Food grade silicone masterbatch 7 parts;

[0090] 2 parts of oligolactic acid-β-cyclodextrin;

[0091] 15 parts of food grade sodium carbonate;

[0092] 2 parts polyethylene glycol oleate;

[0093] 1 part of hydroxymethylcellulose;

[0094] 230 parts of deionized water;

[0095] Antistatic oil agent (TAKEMATO OIL&FAT CO.,LTD) 10 parts.

[0096] The L-lactide has an optical purity >99.8%, a melting point of 99°C, and a water content of 0.1%.

[0097] A method for preparing polylactic acid tow for cigarettes, comprising: rinsing, drying, direct melting, melt extrusion, polymerization, extrusion devolatilization, melting, mixing, microwave treatment, spinning, cooling, winding, ...

Embodiment 3

[0114] Embodiment 3 A kind of polylactic acid tobacco tow

[0115] A polylactic acid tow for cigarettes is made of the following raw materials in parts by weight:

[0116] 95 parts of L-lactide;

[0117] 3 parts of stannous octoate;

[0118] Polyene thermoplastic PP masterbatch 7 parts;

[0119] Food grade silicone masterbatch 5 parts;

[0120] 1.5 parts of oligolactic acid-β-cyclodextrin;

[0121] 10 parts of food grade sodium carbonate;

[0122] 1 part polyethylene glycol oleate;

[0123] 0.7 parts of hydroxymethyl cellulose;

[0124] 210 parts of deionized water;

[0125] Antistatic oil agent (TAKEMATO OIL&FAT CO.,LTD) 6 parts.

[0126] The L-lactide has an optical purity >99.8%, a melting point of 99°C, and a water content of 0.1%.

[0127] A method for preparing polylactic acid tow for cigarettes, comprising: rinsing, drying, direct melting, melt extrusion, polymerization, extrusion devolatilization, melting, mixing, microwave treatment, spinning, cooling, windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com