Lithium/sodium ion battery negative electrode material trinickel tetraselenide/carbon composite material and preparation method thereof

A technology for sodium ion batteries and composite materials, which is applied in the field of preparation of battery negative electrode materials, can solve the problems of reversible deintercalation of sodium ions, and achieve high stability, simple preparation methods, and high first-time coulombic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

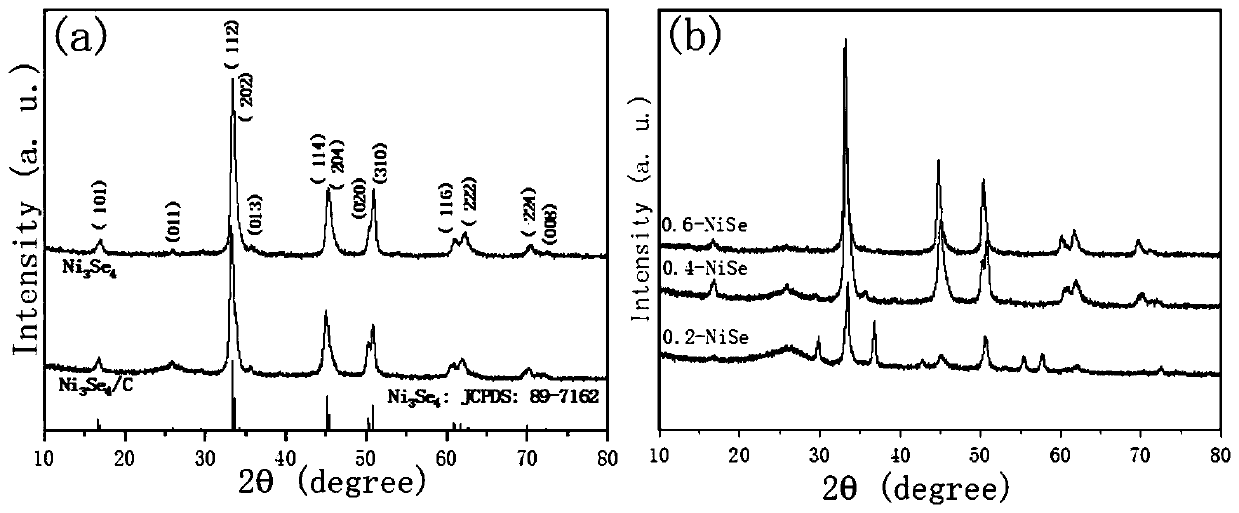

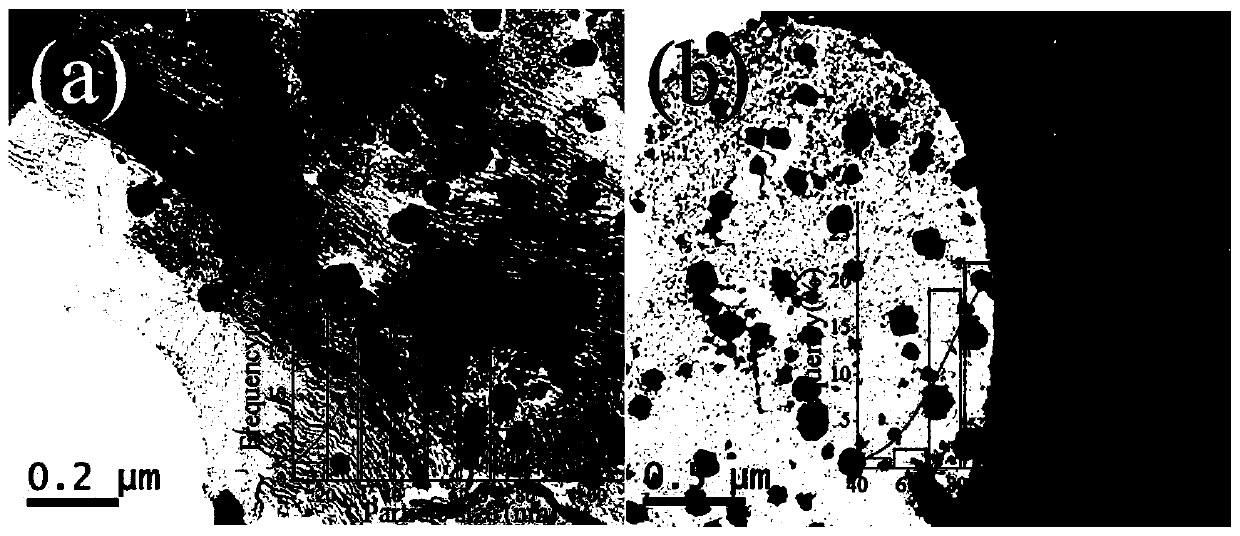

[0031] A kind of lithium / sodium ion battery anode material Ni 3 Se 4 The preparation method of / C composite material, comprises the following steps:

[0032] 1) Put nickel chloride hexahydrate, citric acid and urea together in a mixture of ethanol and distilled water to obtain a mixed solution, heat and stir the mixed solution in a water bath to obtain a green gel, and place the gel in an oven to dry , to obtain the nanosheet nickel salt precursor;

[0033] The mass ratio of described nickel chloride hexahydrate, citric acid and urea is 0.1-0.6: 0.5-2: 3-8;

[0034] 2) Put the nickel salt precursor in a tube furnace, heat up to 200-400°C at a heating rate of 3-10°C / min in a nitrogen environment, and heat it for 1-3 hours to remove organic matter;

[0035]3) Heat the product obtained in step 2) to 700-900°C at a heating rate of 3-10°C / min in a nitrogen environment and keep it warm for 4-6h for heat treatment, and then cool to room temperature to obtain a nickel / carbon compos...

Embodiment 1

[0044] A kind of Ni 3 Se 4 The preparation method of / C composite material, comprises the following steps:

[0045] 1) Put 0.4g of nickel chloride, 1g of citric acid and 5g of urea in a beaker, add a mixture of 150ml of ethanol and 50ml of distilled water into the beaker, and heat and stir the resulting mixed solution in a water bath at 80°C until a green condensation is obtained. Gel, the wet gel is placed in an oven to dry, and dried at 80 ° C for 12 hours to obtain a nano-sheet nickel salt precursor;

[0046] 2) Put the nano-flaky nickel salt precursor into the crucible, raise the temperature to 300°C at a heating rate of 5°C / min in a nitrogen atmosphere, and perform heat treatment at 300°C for 2 hours to remove organic matter;

[0047] 3) The product obtained in step 2) is subjected to high-temperature carbonization treatment, and the temperature is raised to 700°C at a heating rate of 5°C / min in a nitrogen environment, and heat treatment is performed at 700°C for 5 hour...

Embodiment 2

[0055] A kind of Ni 3 Se 4 The preparation method of nanometer material, comprises the following steps:

[0056] 1) Put 0.6g of nickel chloride, 1g of citric acid and 5g of urea in a beaker, add a mixture of 150ml of ethanol and 50ml of distilled water into the beaker, heat and stir the resulting solution in a water bath at 80°C until a green gel is obtained , place the wet gel in an oven to dry, and dry at 80° C. for 12 hours to obtain a nano-sheet nickel salt precursor;

[0057] 2) Then put the nano-flaky nickel salt precursor into the crucible, raise the temperature to 300°C at a heating rate of 5°C / min under nitrogen atmosphere, and perform heat treatment at 300°C for 2 hours to remove organic matter;

[0058] 3) Carry out high-temperature carbonization treatment on the product obtained in step 2), raise the temperature to 700°C at a heating rate of 5°C / min under nitrogen atmosphere, conduct heat treatment at 700°C for 5 hours, and cool to room temperature , the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com