Carbon tube supported ultra-small VN hydrogen production electrocatalyst, synthesis method and application

A technology of electrocatalyst and synthesis method, applied in the direction of chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of complex preparation process and high manufacturing cost, and achieve good electrochemical performance, improved efficiency, The unique effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

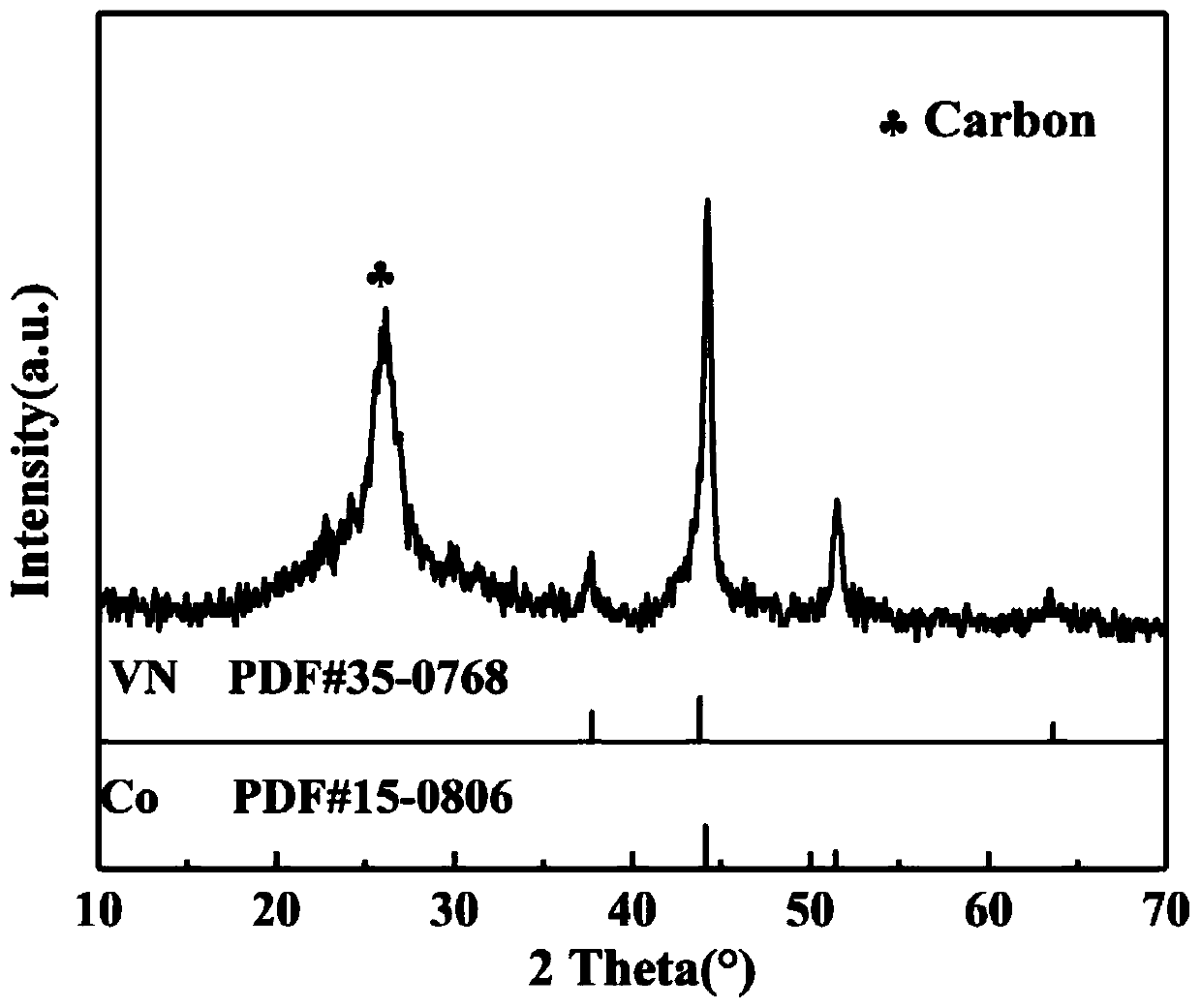

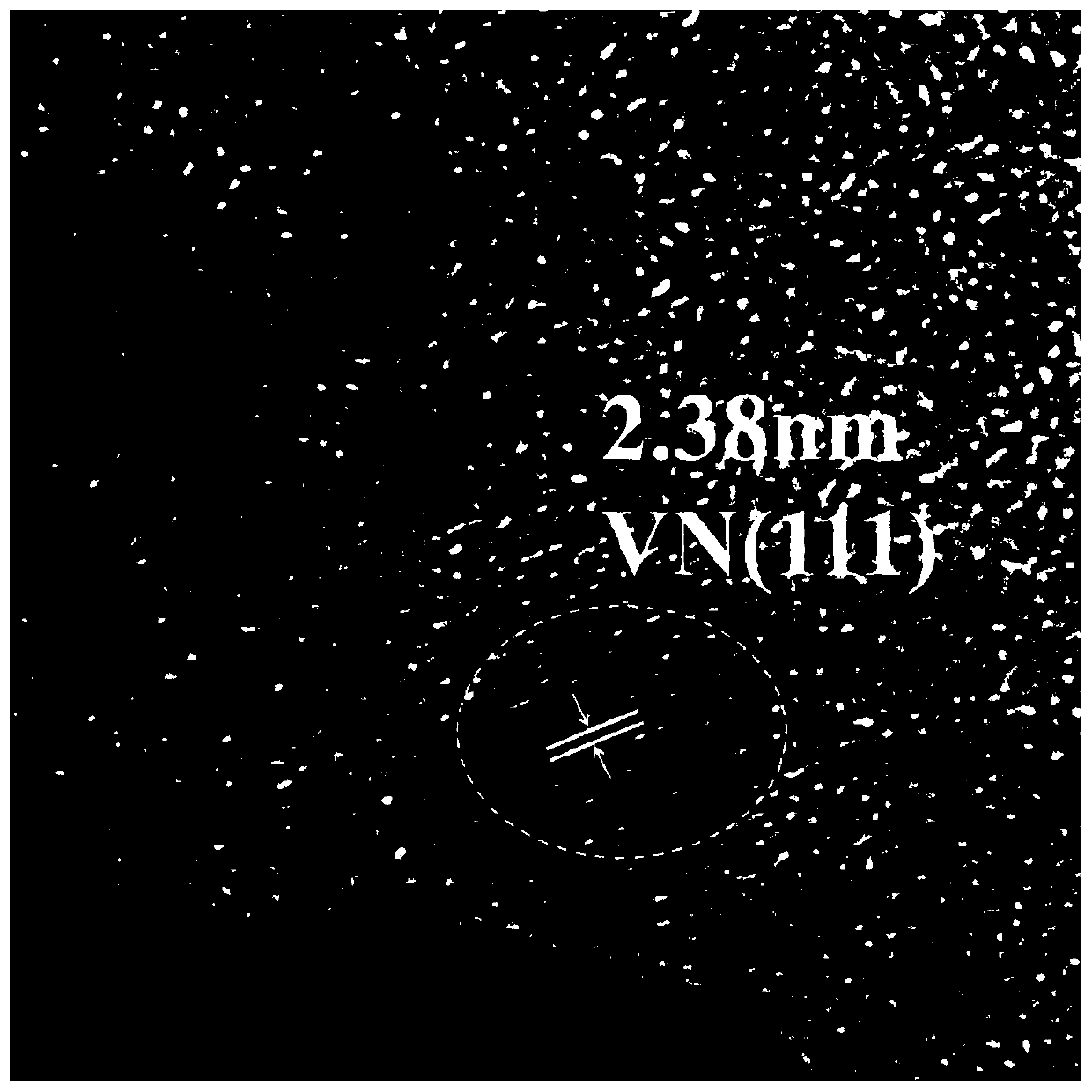

[0026] The synthesis method of the carbon tube-loaded cobalt-doped ultra-small VN hydrogen-producing electrocatalyst of this embodiment comprises the following steps:

[0027] S1. Put 1500mg of dicyandiamide, 100mg of cobalt chloride hexahydrate and 0.025g of ammonium metavanadate in a mortar and grind for 20 minutes to mix the raw materials evenly. Put the obtained mixture into a porcelain boat and place the porcelain boat on In a tube-type atmosphere furnace, two furnace plugs are placed at each end of the quartz tube.

[0028] S2. Introduce the inert gas argon into the tube, and then carry out pumping and gas replenishment three times each. The heating rate was raised to 500°C at a rate of 10°C / min, and kept for 2 hours, and then raised to 900°C at a rate of 5°C / min, and kept for 2 hours.

[0029] S3. When the sample is cooled to room temperature, take out the sample and grind it for 20min, then use 1mol / L H 2 SO 4 Pickling for 12h. After acid washing, the sample was wa...

Embodiment 2

[0031] The synthesis method of the carbon tube-loaded cobalt-doped ultra-small VN hydrogen-producing electrocatalyst of this embodiment comprises the following steps:

[0032] S1. Put 1500mg of melamine, 0.75mg of cobalt chloride hexahydrate and 0.025g of ammonium metavanadate in a mortar and grind for 20 minutes to mix the raw materials evenly. In a type atmosphere furnace, two furnace plugs are placed at each end of the quartz tube.

[0033] S2. Introduce the inert gas argon into the tube, and then carry out pumping and gas replenishment three times each. The heating rate was raised to 500°C at a rate of 10°C / min, and kept for 2 hours, and then raised to 800°C at a rate of 5°C / min, and kept for 2 hours.

[0034] S3. When the sample is cooled to room temperature, the sample is taken out and ground for 20 minutes, and then acid-washed with 1 mol / L H2SO4 for 12 hours. After acid washing, the sample was washed and centrifuged three times alternately with ultrapure water and ab...

Embodiment 3

[0036] The synthesis method of the carbon tube-loaded cobalt-doped ultra-small VN hydrogen-producing electrocatalyst of this embodiment comprises the following steps:

[0037] S1. Put 1500mg of dicyandiamide, 100mg of cobalt chloride hexahydrate and 0.05g of ammonium metavanadate in a mortar and grind for 20 minutes to mix the raw materials evenly. Put the obtained mixture into a porcelain boat and place the porcelain boat on In a tube-type atmosphere furnace, two furnace plugs are placed at each end of the quartz tube.

[0038] S2. Introduce the inert gas argon into the tube, and then carry out pumping and gas replenishment three times each. The heating rate was raised to 500°C at a rate of 10°C / min, and kept for 2 hours, and then raised to 900°C at a rate of 5°C / min, and kept for 2 hours.

[0039] S3. When the sample is cooled to room temperature, take out the sample and grind it for 20min, then use 1mol / L H 2 SO 4 Pickling for 12h. After acid washing, the sample was was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com