Preparation method of submicron magnesium hydroxide

A magnesium hydroxide, sub-micron technology, applied in the field of inorganic materials and microchemical engineering, can solve the problems of increasing the complexity of the production process and production costs, achieve continuous precipitation process, strong process controllability, and increase growth rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

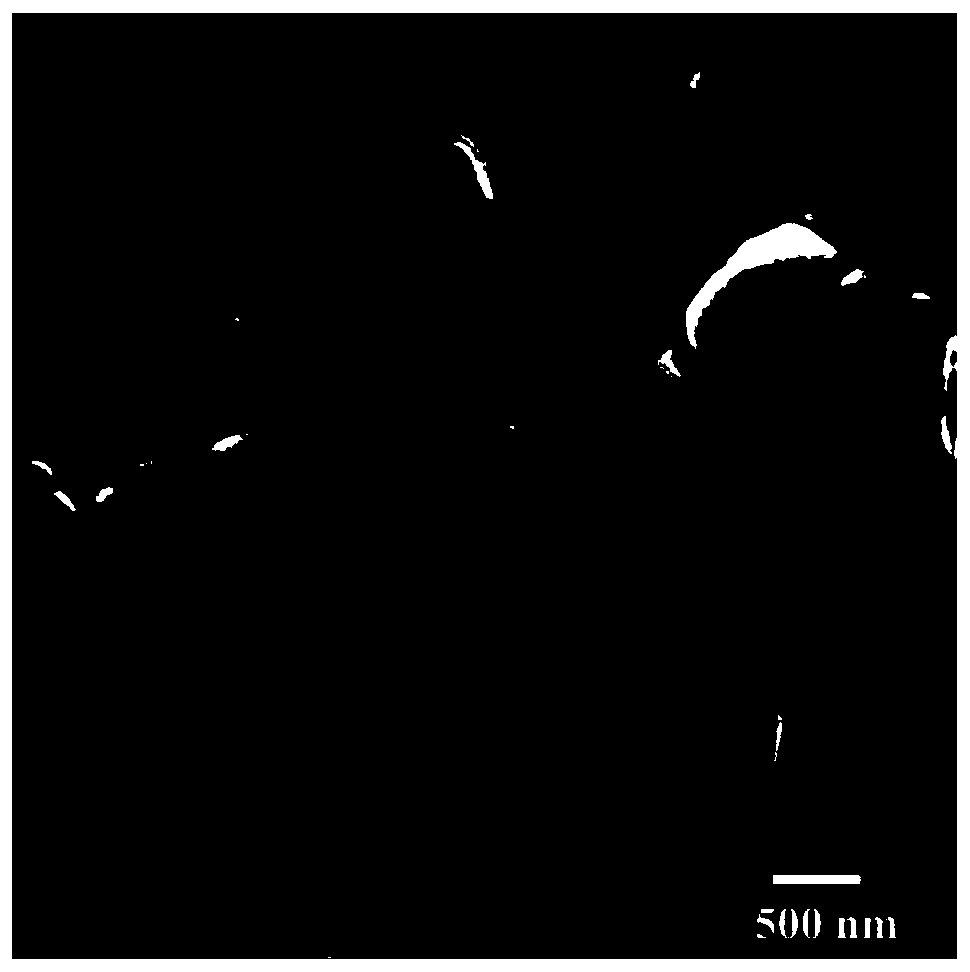

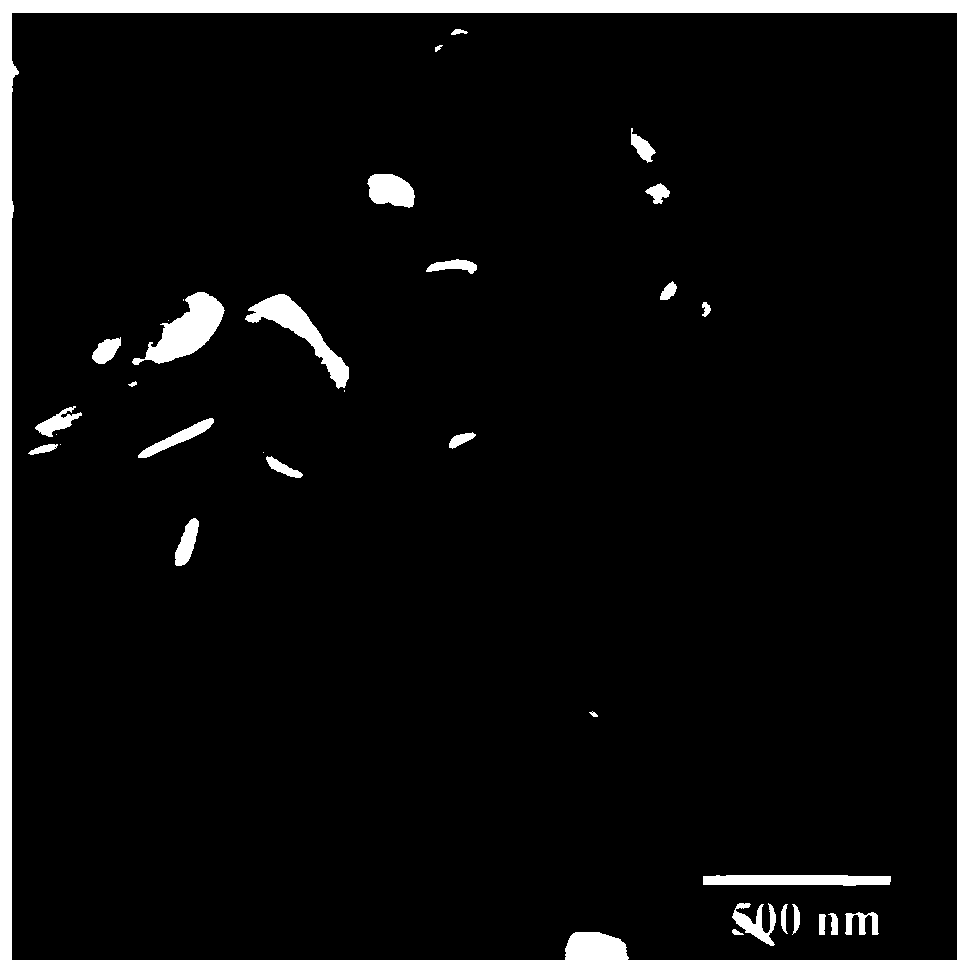

Embodiment 1

[0024] Configure MgCl separately 2 500mL each of aqueous solution and NaOH and NaCl mixed aqueous solution, in which MgCl 2 The concentration is 1.0mol / L, the NaOH concentration is 1.6mol / L, and the NaCl concentration is 2.4mol / L. The above two aqueous solutions all entered the microreactor for contact, mixing and reaction at a flow rate of 150mL / min, n(Mg 2+ ):n(OH - )=1:1.6, the reaction temperature is 60°C. The reaction slurry flows out from the outlet of the micro-reactor and directly enters the hydrothermal synthesis kettle, and is subjected to hydrothermal treatment at 180° C., and the hydrothermal time is 4 hours. After the hydrothermal treatment, 200 mL of the hydrothermally reacted reaction slurry was placed in a Buchner funnel with an inner diameter of 9 cm for vacuum filtration, and the filtration time was determined to be 500 s. After washing three times with deionized water, place it in an oven and dry for 6 hours to obtain submicron magnesium hydroxide. The ...

Embodiment 2

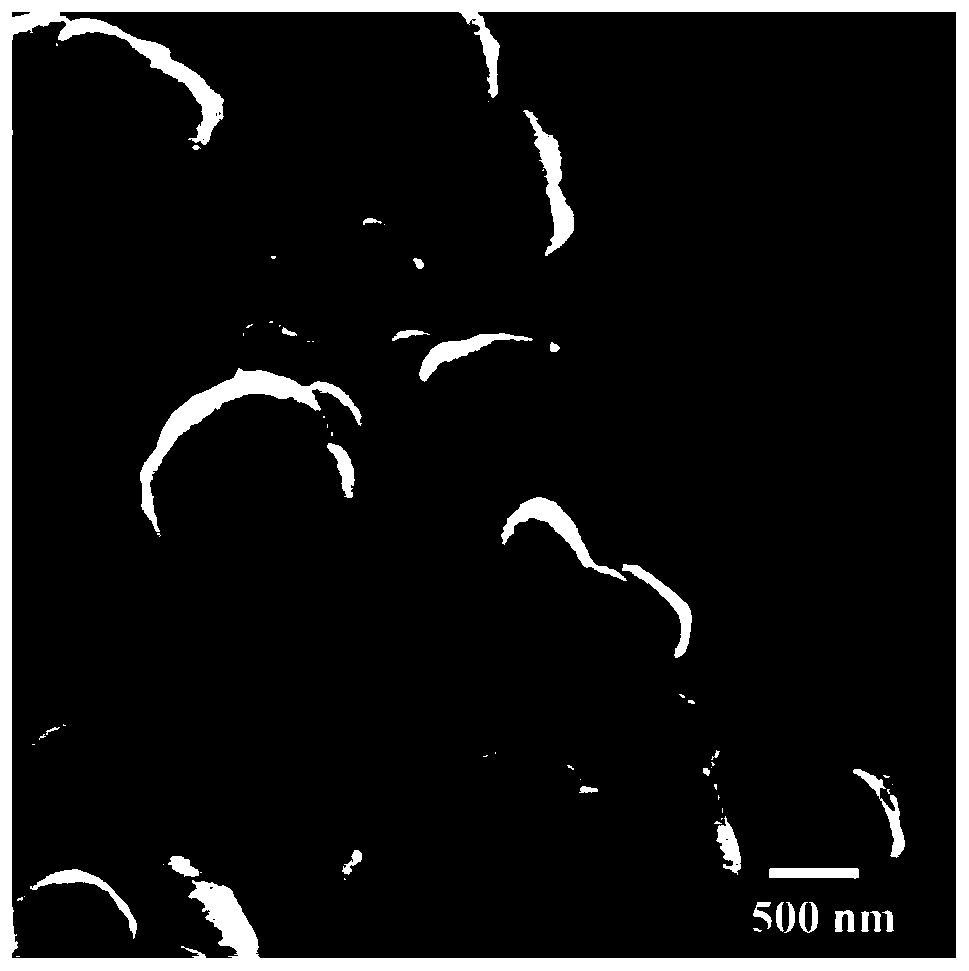

[0026] Configure MgCl separately 2 500mL each of aqueous solution and NaOH and NaCl mixed aqueous solution, in which MgCl 2 The concentration is 0.5mol / L, the NaOH concentration is 1.0mol / L, and the NaCl concentration is 3.0mol / L. The above two aqueous solutions all entered the microreactor for contact, mixing and reaction at a flow rate of 150mL / min, n(Mg 2+ ):n(OH - )=1:2.0, the reaction temperature is 60°C. The reaction slurry flows out from the outlet of the micro-reactor and directly enters the hydrothermal synthesis kettle, and is subjected to hydrothermal treatment at 180° C., and the hydrothermal time is 4 hours. After the hydrothermal treatment, 200 mL of the reaction slurry after the hydrothermal reaction was taken and vacuum-filtered in a Buchner funnel with an inner diameter of 9 cm, and the suction-filtration time was determined to be 420 s. After washing three times with deionized water, place it in an oven and dry for 6 hours to obtain submicron magnesium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com