Core-shell structured wave absorbing material as well as preparation method and application thereof

A technology of wave absorbing material and core-shell structure, applied in the field of wave absorbing material, can solve the problems such as impedance mismatch that plagues scientific researchers, has not been well solved, uneven distribution of wave absorbing agent, etc., and achieves a convenient microscopic appearance. Control, ensure normal performance, the effect of excellent impedance matching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

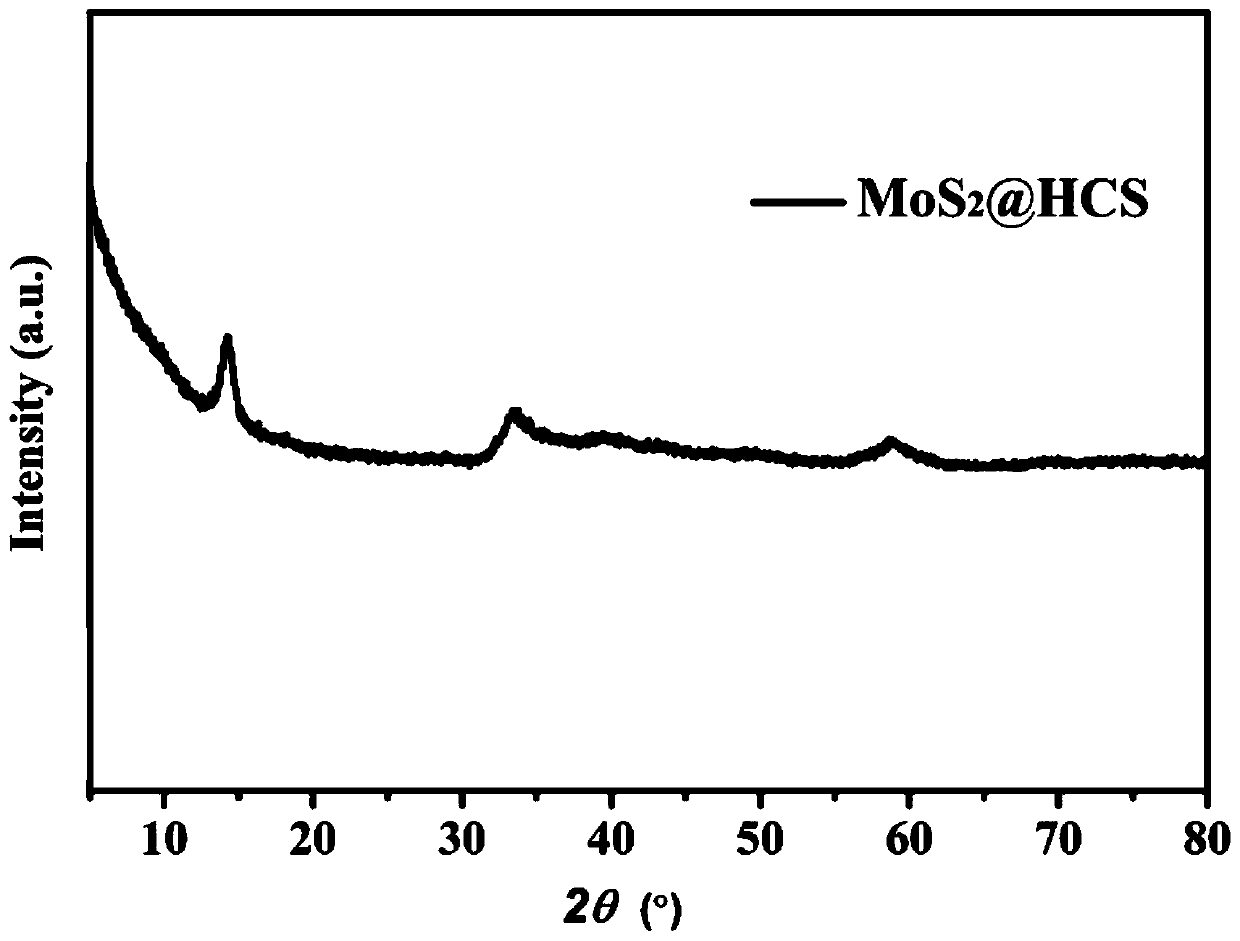

Embodiment 1

[0044] (1) Using the Stober method (reference: Werner Stober et.al. Controlled Growth of Monodisperse Silica Spheres in the Micron Size Range, Journal of colloid and interface science, 1968, 26, 62-69) to prepare highly dispersed hollow carbon spheres . The hollow carbon spheres (particle diameter is 250nm) that takes by weighing 100mg is placed in the beaker of 50mL, after adding 25mL formamide and 5mL methyl alcohol, fully stir 1h to obtain mixed solution; Take by weighing 2.0g sodium molybdate dihydrate (Na 2 MoO 4 .2H 2 O) and 4.0g thioacetamide (CH 3 CSCH 2 ) into the above-mentioned mixed solution in turn and stirred for 2 hours respectively to make it fully dissolve, then transfer the obtained reaction solution to a solvothermal reaction inner bushing with a capacity of 50 mL, place the inner bushing in a stainless steel outer sleeve and seal it, React at 200°C for 24h.

[0045] (2) After the reaction, put the product in a centrifuge tube and centrifuge at 10,000 r...

Embodiment 2

[0050] The preparation steps are basically the same as in Example 1, the only difference being: the sodium molybdate dihydrate described in the step (1) is replaced by sodium tungstate to obtain the core-shell structure type WS 2 @HCS composite microwave absorber.

Embodiment 3

[0052] The preparation steps are basically the same as in Example 1, except that the sodium molybdate dihydrate described in step (1) is replaced by sodium vanadate, and the thioacetamide is replaced by sodium tellurate to obtain a core-shell Structural VTe 2 @HCS composite microwave absorber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com