Algae cultivation photobioreactor

A photobioreactor and reactor technology, applied in the field of algae cultivation photobioreactor, can solve the problems of temperature instability, low population density, high cost, etc., to shorten the growth cycle, increase the growth speed, improve the quality and quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

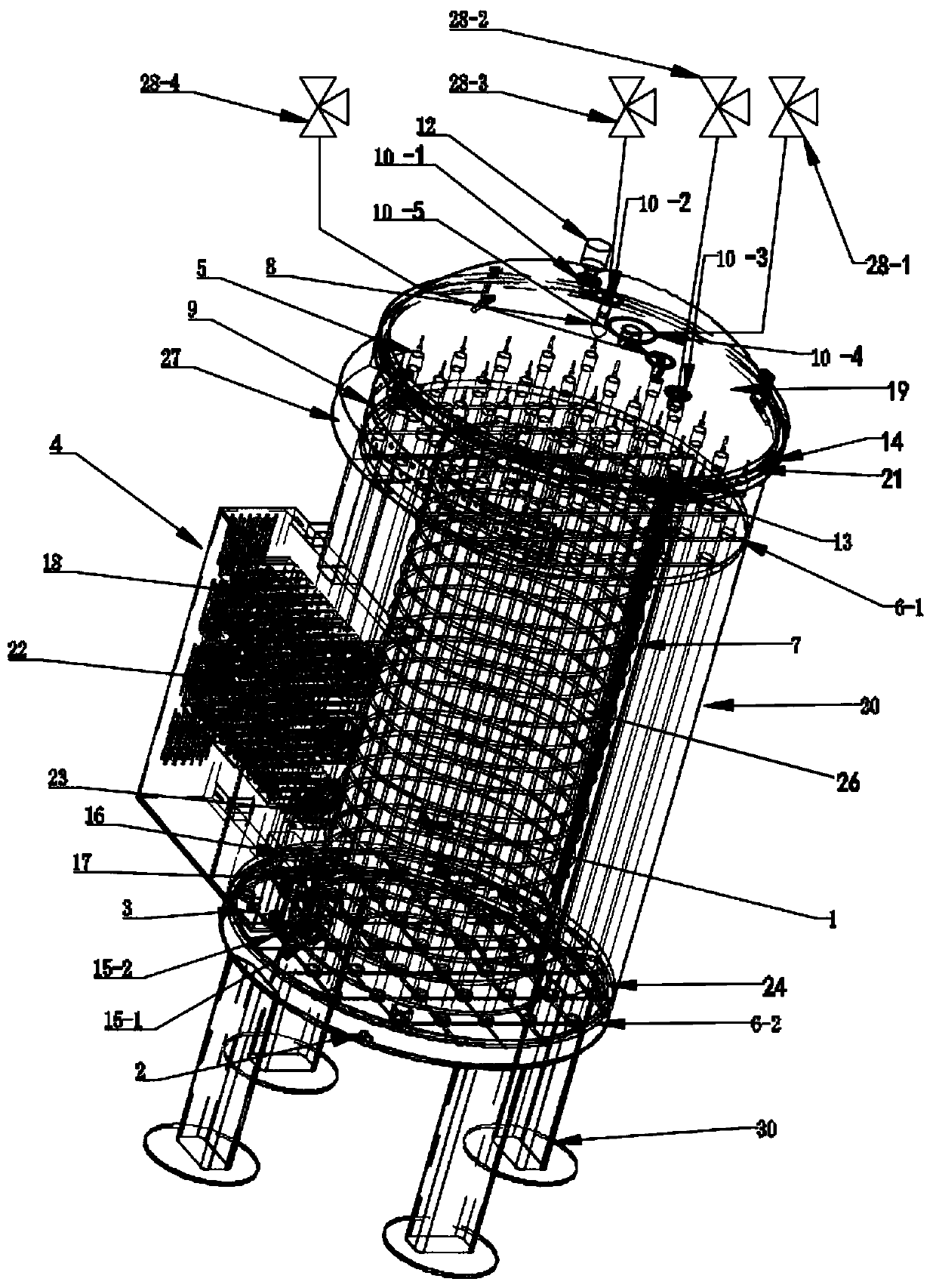

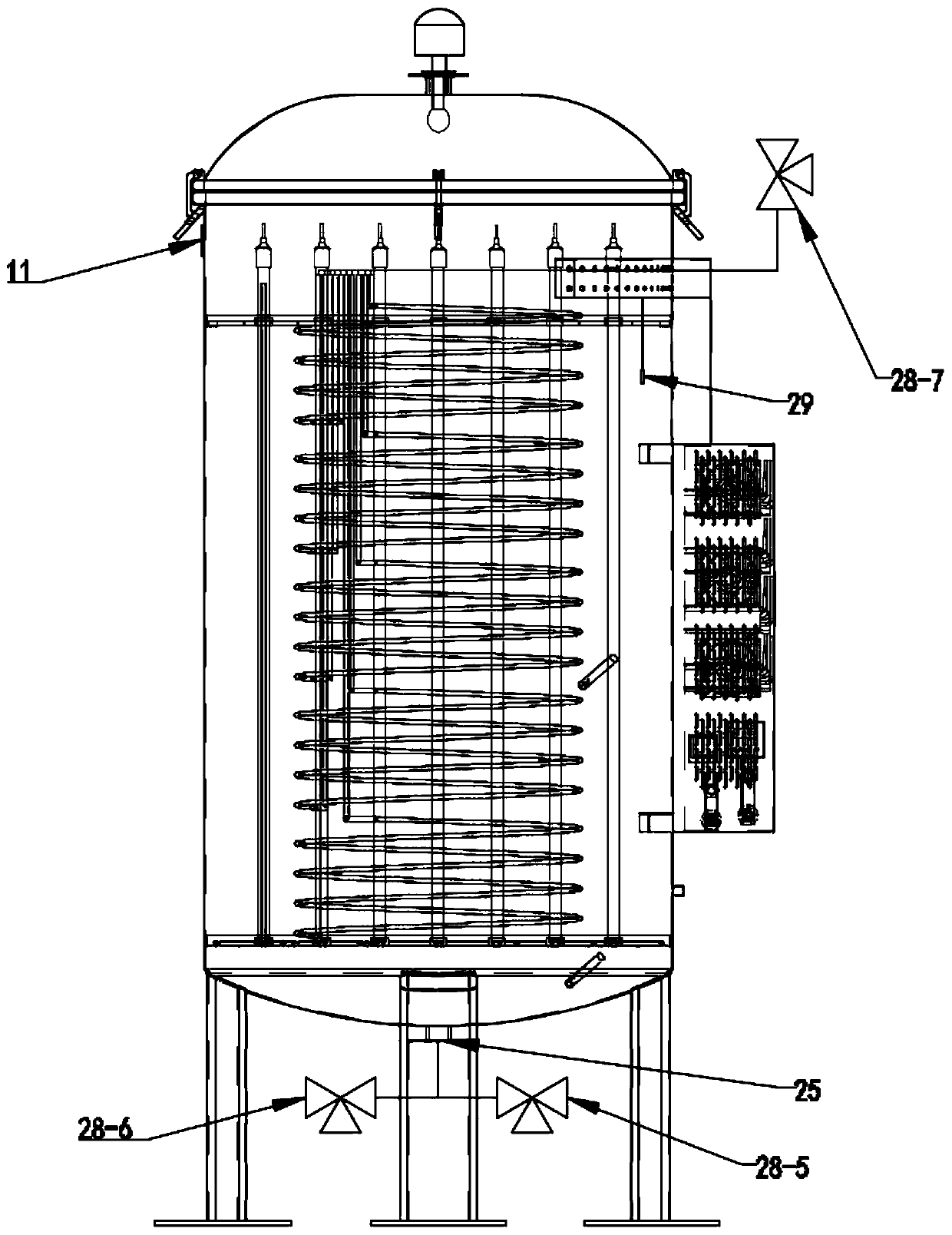

[0102] The structure of the photobioreactor for algae cultivation in this embodiment is as follows figure 1 with 2 As shown, the algae or algae cells of this embodiment are Haematococcus pluvialis or Haematococcus pluvialis cells, and the algae species are Haematococcus pluvialis species. The main body of the photobioreactor for algae cultivation is a closed reactor tank 20, which is a vertical cylinder with a diameter of 100cm and a height of 225cm. The designed solution capacity is 1000L. The closed reactor tank 20 is The material is stainless steel.

[0103] The top of the closed reactor tank body 20 is provided with a detachable face cover 19, and the face cover 19 is provided with a gas connector 10-1, a cleaning fluid connector 10-2, a raw material algae species connector 10-3, a make-up water connector 10-4 and The culture fluid connector 10-5, the face cover 19 is connected with the closed reactor tank body 20 through the buckle 13 and sealed, the face cover 19 and the cl...

Embodiment 2

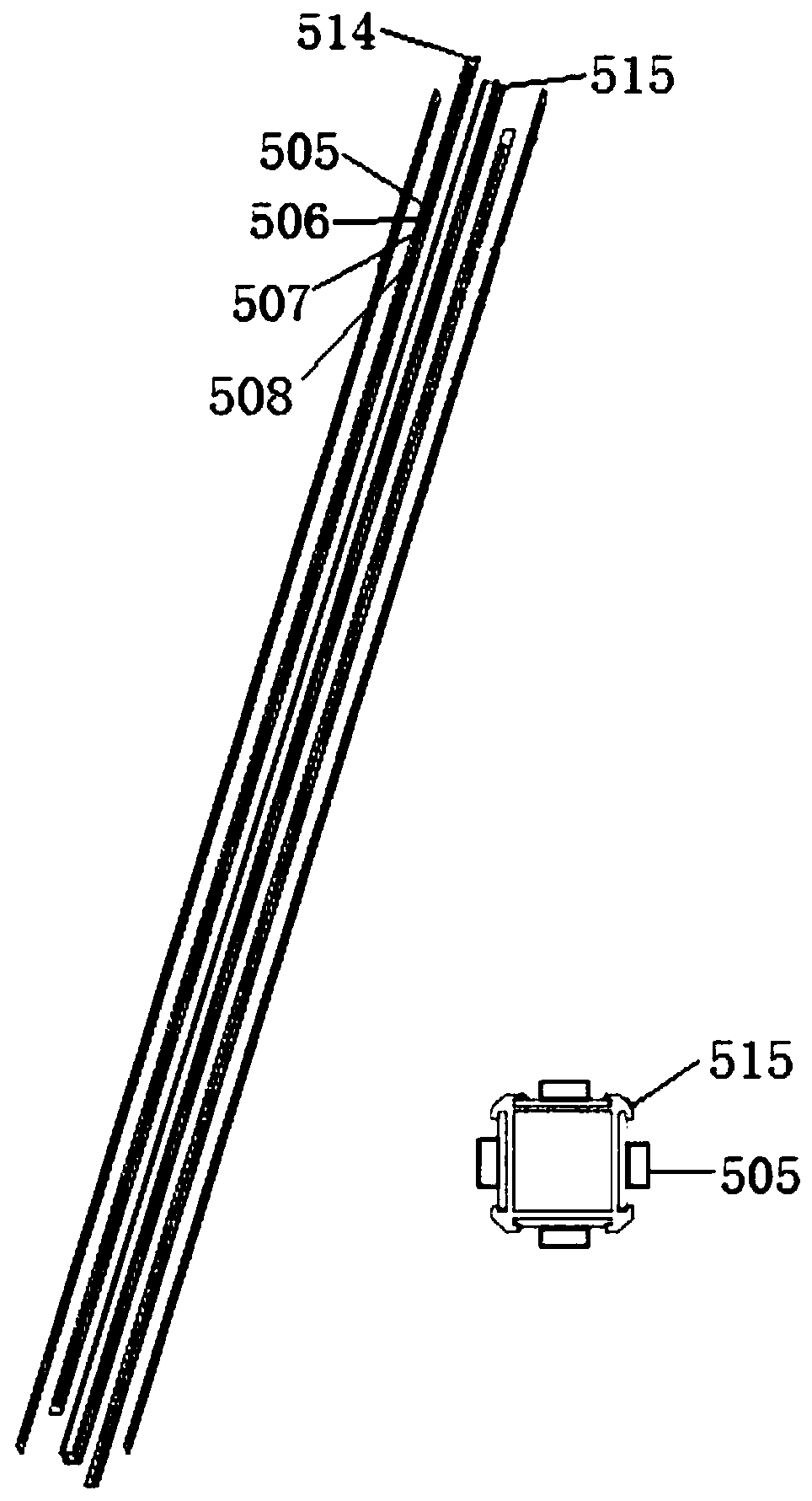

[0137] The structure of the waterproof LED lamp 5 of this embodiment is as follows Image 6 As shown, a single LED chip of the waterproof LED lamp 5 emits light of multiple wavelengths, that is, each LED chip can emit light with wavelengths of 300-400nm, 400-500nm, 500-600nm, and 600-780nm. All LED chips are connected to the first Five LED drive controllers 500, one fifth LED drive controller 500 controls all LED chips, so that the power of light of multiple wavelengths is increased or decreased at the same time, and the energy is also increased or decreased at the same time.

[0138] The other structure of the photobioreactor of this embodiment is the same as that of the first embodiment.

Embodiment 3

[0139] Example 3 Usage

[0140] The photobioreactor for algae cultivation used in this embodiment is the photobioreactor for algae cultivation of Example 1, and its use method includes the following steps:

[0141] (1) Input the raw material algae into the reactor tank 20 through the fourth valve 28-2, and input the culture solution into the closed reactor tank 20 through the second valve 28-4;

[0142] (2) Turn on the power, start the control system, and observe the liquid level change through the liquid level sensor 2;

[0143] (3) Start the waterproof LED lamp 5 through the LED drive controller 18, and control the illumination parameters, specifically, the light quantum flux density is 4×10 5 -6×10 5 μmol / m 2 ·S, the light time is 60 hours, the power is 60-7800W;

[0144] (4) Turn on the carbon dioxide source and the air source, and control the carbon dioxide flow to 0.3L / min and the air flow to 5L / min through the carbon dioxide flowmeter 15-1 and the air flowmeter 15-2, respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com