Microfluidic-based high-flux crystallization condition screening method

A conditional screening, high-throughput technology, applied in measurement devices, material analysis using radiation diffraction, material analysis by optical means, etc., can solve the cost of manpower, material resources, time, increase the difficulty of result analysis, and huge reagent consumption. and other problems, to achieve the effect of large screening range, low cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

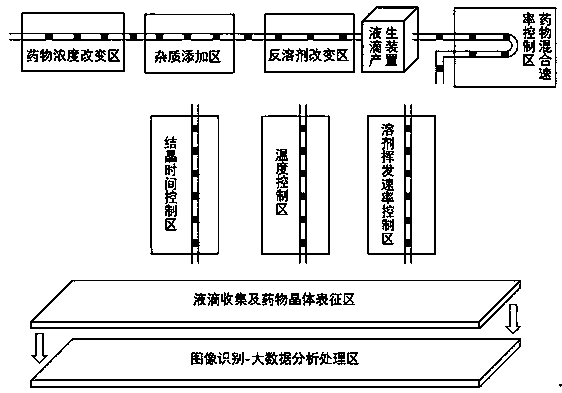

[0035] The high-throughput crystallization condition screening method based on microfluidics in this embodiment is used to screen the crystallization conditions of indomethacin, such as figure 1 Flowchart of the screening method for high-throughput crystallization conditions based on microfluidics.

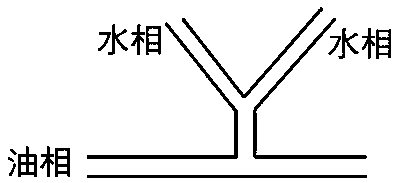

[0036] Such as figure 2 , this example uses the "T" channel method, co-flow focusing method, co-axial flow method, etc. can also be used; the microfluidic chip is prepared by molding polydimethylsiloxane (polydimethylsiloxane, PDMS) , Injection molding, soft photolithography, etc. can also be used.

[0037] The microfluidic-based high-throughput crystallization condition screening method of this embodiment comprises the following steps:

[0038] S1. Using PDMS and aluminum sheets as materials, use Adobe Illustrator CC 2018 software to design the "T" droplet generation channel structure, or use other software such as SolidWorks, AutoCAD, CorelDRAW, etc., which can be used for ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com