Electrochemical method and monitoring device for in-situ monitoring of membrane surface fouling status

An electrochemical and membrane surface technology, applied in the direction of measuring devices, electrochemical variables of materials, scientific instruments, etc., can solve the problems of increased power consumption, reduced membrane performance such as flux and conductivity, shortened membrane life, and economic feasibility. Achieve the effect of precise device and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

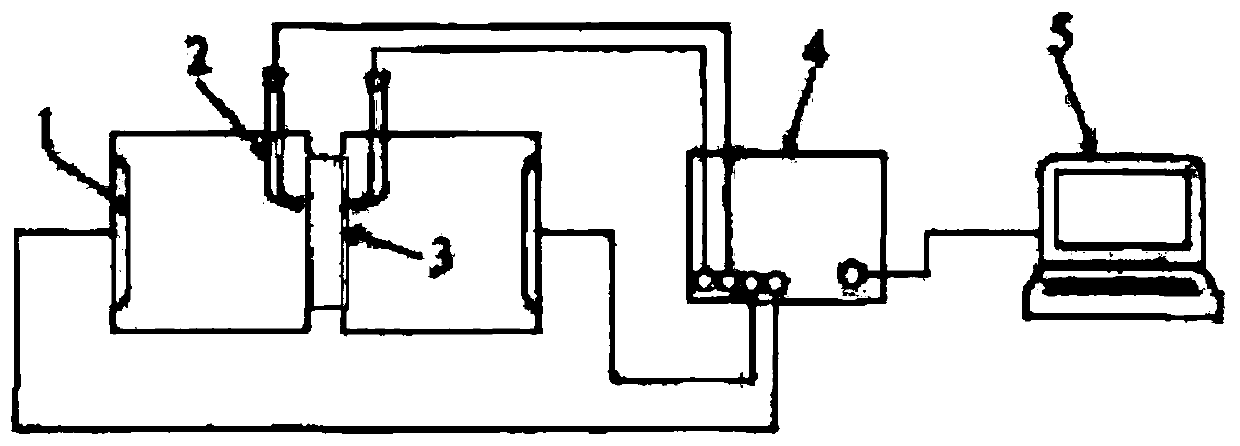

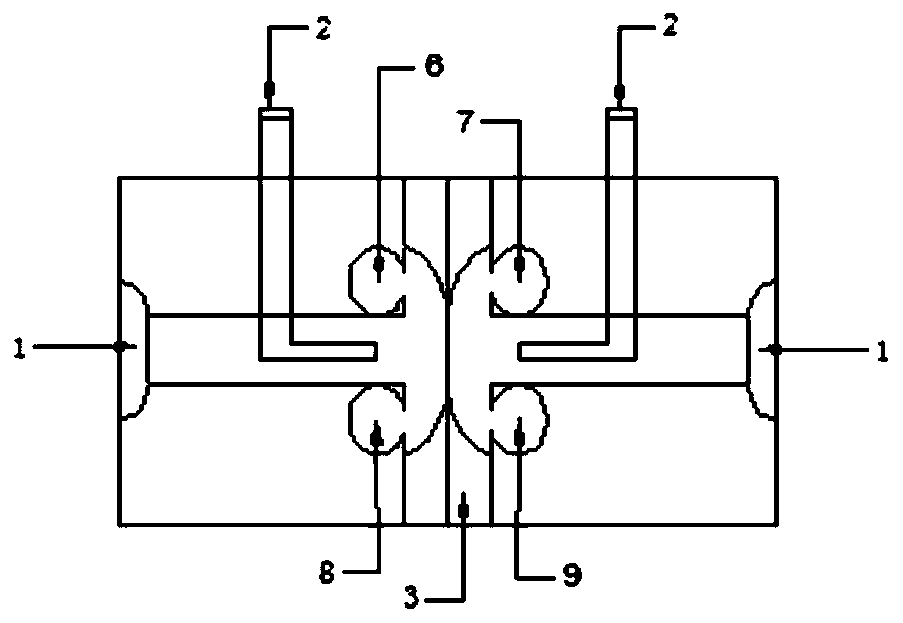

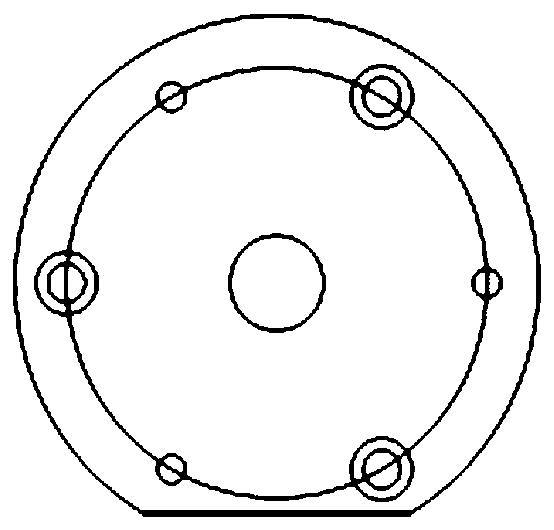

specific Embodiment 1

[0048] Sodium alginate (Sodium alginate, SA) was selected as a typical pollutant in the research of membrane fouling, and AEM-Type I—0.5mol / L NaCl+0.5%SA solution system was used. Put the ion exchange membrane to be tested into the four-electrode system test device, and then connect the four-electrode system test device with the electrochemical workstation and two gear pumps. Pour the prepared solution with a concentration of 0.5mol / LNaCl+0.5% SA into the liquid storage tank, place the liquid storage tank in a constant temperature bath, and set the temperature at 20°C. Start the gear pump and adjust the flow rate of the gear pump so that the flow rate is 2 cm / s. After the flow rate and potential difference were stabilized, the impedance spectrum was obtained by the electrochemical impedance spectroscopy method of the electrochemical workstation. Use AEM-TypeII-0.5mol / L NaCl+0.5%SA solution system, and then change the flow rate of the gear pump to 2, 3, 4cm / s to carry out the ...

specific Embodiment 2

[0051] Sodium alginate (Sodium alginate, SA) was selected as a typical pollutant in the research of membrane fouling, and AEM-TypeII-0.1mol / L NaCl+0.5%SA solution system was used. Put the ion exchange membrane to be tested into the four-electrode system test device, and then connect the four-electrode system test device with the electrochemical workstation and two gear pumps. Pour the prepared NaCl solution with a concentration of 0.1 mol / L into the liquid storage tank, place the liquid storage tank in a constant temperature bath, and set the temperature at 20°C. Start the gear pump and adjust the flow rate of the gear pump so that the flow rate is 1 cm / s. After the flow rate and potential difference were stabilized, the impedance spectrum was obtained by the electrochemical impedance spectroscopy method of the electrochemical workstation. Then change the concentration of electrolyte (NaCl) solution to 0.3mol / L and 0.5mol / L to carry out the same measurement to investigate the...

specific Embodiment 3

[0054] Sodium alginate (Sodium alginate, SA) was selected as a typical pollutant in the research of membrane fouling, and AEM-TypeII-0.1mol / L NaCl+0.5%SA solution system was used. Put the ion exchange membrane to be tested into the four-electrode system test device, and then connect the four-electrode system test device with the electrochemical workstation and two gear pumps. Pour the prepared NaCl solution with a concentration of 0.1 mol / L into the liquid storage tank, place the liquid storage tank in a constant temperature bath, and set the temperature at 20°C. Start the gear pump and adjust the flow rate of the gear pump so that the flow rate is 1 cm / s. After the flow rate and potential difference were stabilized, the impedance spectrum was obtained by the electrochemical impedance spectroscopy method of the electrochemical workstation. Then the pollutant SA was replaced by bovine serum albumin BSA for the same determination to investigate the effect of different pollutant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com