Method for preparing simulated EVA (ethylene vinyl acetate) flower from modified sodium alginate-carbon fiber

A technology of sodium alginate and carbon fiber, which is applied in the field of artificial flowers, can solve the problems of poor water resistance and wear resistance, and achieve the effects of improving water resistance, improving hardness and brittleness, and improving tensile strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

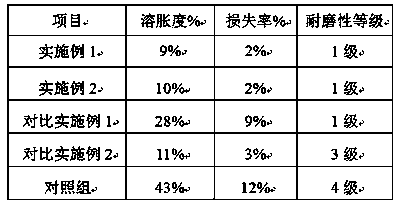

Examples

Embodiment 1

[0029] A method for preparing artificial EVA flowers with modified sodium alginate-carbon fiber, is characterized in that, comprises the following steps, and following raw materials are by weight:

[0030] (1) Preparation of polyurethane modified sodium alginate:

[0031] Add 5 parts of modifier epoxy-terminated polyurethane emulsion to 10 parts of sodium alginate aqueous solution, adjust the pH to 8, stir and react at 70°C for 65 minutes, and use acetone Soxhlet extraction to obtain epoxy-terminated polyurethane modified alginic acid sodium;

[0032] Wherein, the sodium alginate aqueous solution concentration is 2%;

[0033] (2) Surface treatment of carbon fiber:

[0034] After cleaning 6 parts of carbon fiber in acetone solution, rinse it with absolute ethanol, dry it at room temperature, and then immerse it in a rare earth lanthanum chloride solution with a pH of 5. After soaking for 1 hour, dry it under vacuum at 115°C to obtain a surface treated carbon fiber;

[0035]...

Embodiment 2

[0042] A method for preparing artificial EVA flowers with modified sodium alginate-carbon fiber, is characterized in that, comprises the following steps, and following raw materials are by weight:

[0043] (1) Preparation of polyurethane modified sodium alginate:

[0044] Add 10 parts of modifier epoxy-terminated polyurethane emulsion to 20 parts of sodium alginate aqueous solution, adjust the pH to 9, stir and react at 80°C for 55 minutes, and use acetone Soxhlet extraction to obtain epoxy-terminated polyurethane modified alginic acid sodium;

[0045] Wherein, the sodium alginate aqueous solution concentration is 4%;

[0046] (2) Surface treatment of carbon fiber:

[0047] After cleaning 9 parts of carbon fiber in acetone solution, rinse it with absolute ethanol, dry it at room temperature, and then immerse it in a rare earth lanthanum chloride solution with a pH of 5. After soaking for 2 hours, dry it under vacuum at 125°C to obtain a surface treated carbon fiber;

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com