Body with composite coating, preparation method and application of body with composite coating, and solar cell

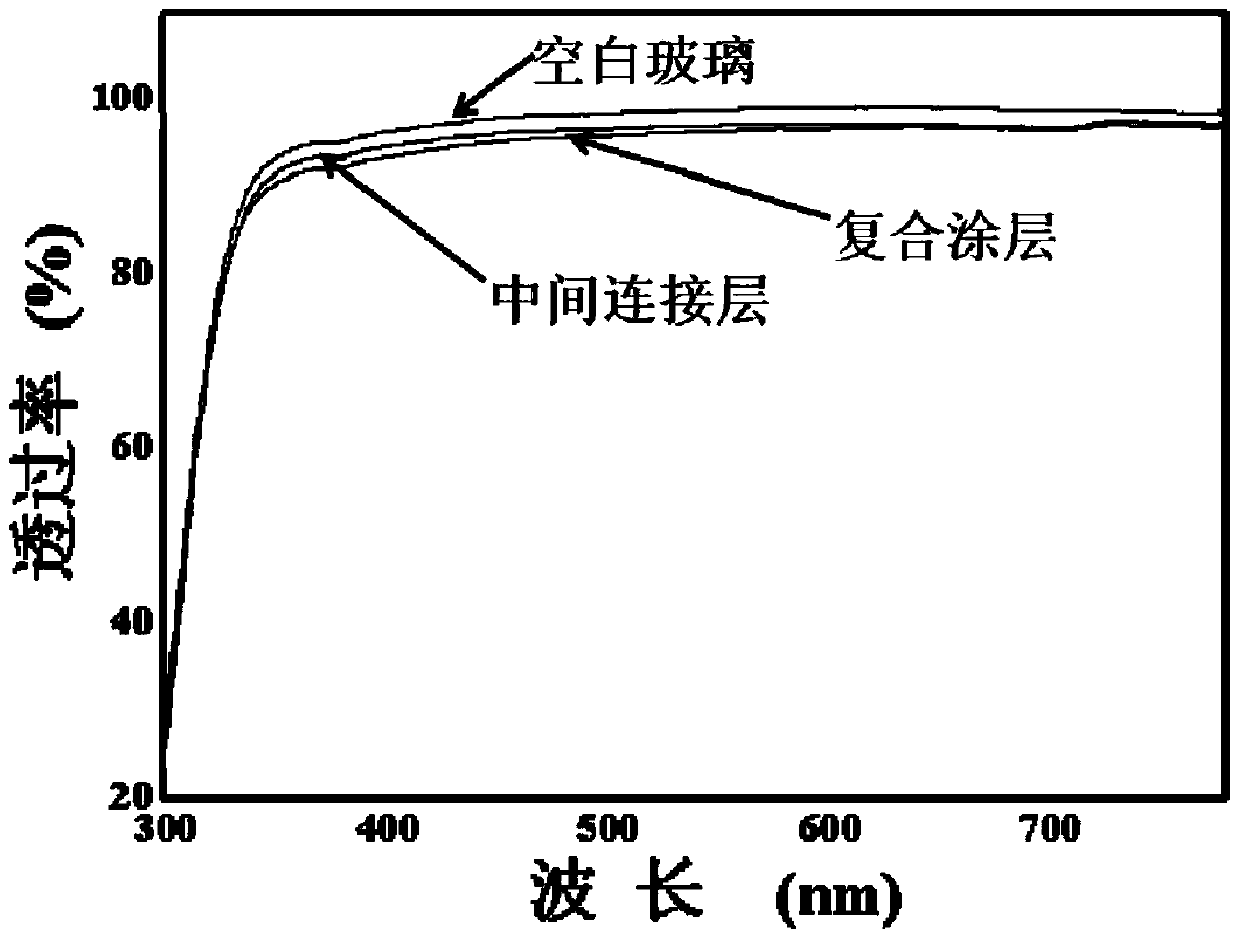

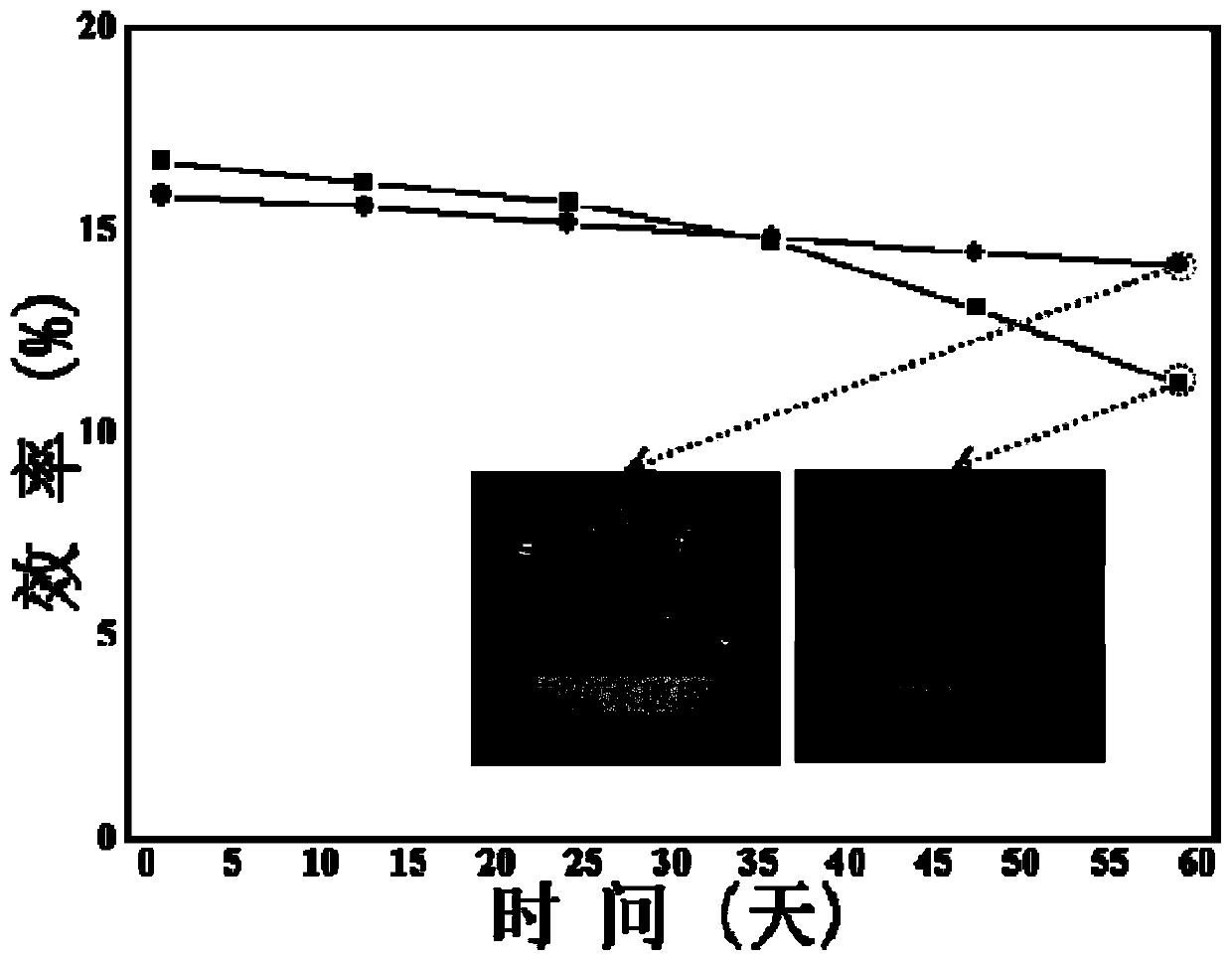

A composite coating and polymer sheet technology, applied in the field of solar cells, can solve the problems of solar panel efficiency of only 29.76%, lower and higher transmission rates, etc., and achieve good super-hydrophobic properties, light transmittance, and film-forming quality Good, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

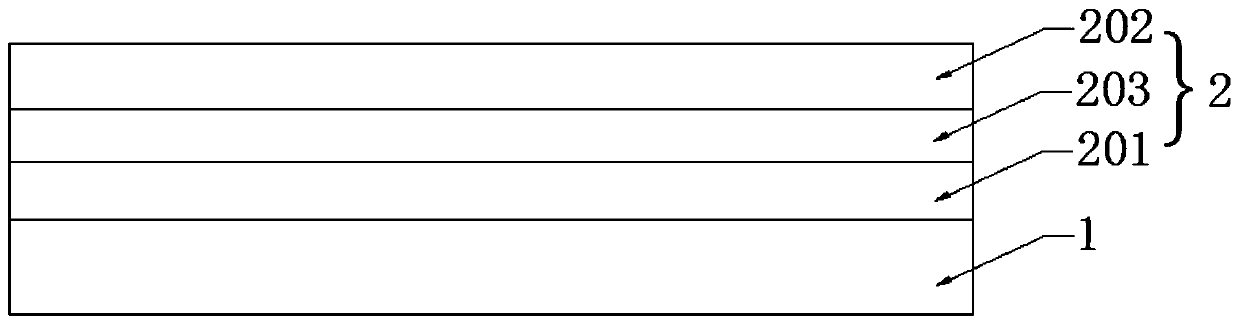

[0080] According to another aspect of the present invention, there is provided a method for preparing the above-mentioned body with a composite coating, comprising the following steps:

[0081] (a) providing a substrate, and then adopting a chemical vapor deposition method to deposit a nano-silicon dioxide layer on the surface of the substrate;

[0082] (b) providing a hydrolyzate of the silane coupling agent;

[0083] (c) providing a superhydrophobic silica suspension;

[0084] (d) coating the hydrolyzed product of the silane coupling agent and the superhydrophobic silicon dioxide suspension on the surface of the nanometer silicon dioxide layer in sequence, and obtaining the body with the composite coating after curing.

[0085] The process of the above method is scientific and reasonable, the structure of the obtained composite coating is stable, the composite coating is not easy to detach from the surface of the substrate, and has super hydrophobicity, stain resistance and...

Embodiment 1

[0122] A method for preparing a body with a composite coating, comprising the following steps:

[0123] (a) A nano-silicon dioxide layer is deposited on the surface of the mica sheet by low-temperature chemical vapor deposition; the gas source is SiH with a volume ratio of 1:6 4 and N 2 O; the thickness of the nano-silicon dioxide layer is 1 μm, the particle size of the silicon dioxide is 30nm; the deposition temperature is 330°C, the radio frequency power is 15W, the deposition pressure is 200Pa, and the deposition time is 15min;

[0124](b) Mixing and reacting γ-aminopropyltriethoxysilane and an aqueous solution of ammonia for 70 minutes to obtain a hydrolyzate of a silane coupling agent;

[0125] (c) silicon dioxide and trimethylmethoxysilane are mixed and reacted to obtain a silicon dioxide suspension;

[0126] (d) Spray the hydrolyzate of the silane coupling agent and the silica suspension on the surface of the nano-silica layer in turn, and form an intermediate connect...

Embodiment 2-4

[0128] A kind of preparation method of band composite coating body, different from embodiment 1, in embodiment 2-4, SiH 4 and N 2 The volume ratios of O are 1:5, 1:0.1 and 1:2, respectively. All the other are identical with embodiment 1.

[0129] SiH in embodiment 2-4 4 and N 2 The volume ratio of O is within the preferred range of the present invention, wherein SiH in embodiment 3-4 4 and N 2 The volume ratio of O is within a further preferred range of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com