Preparation method for vanadium dioxide films

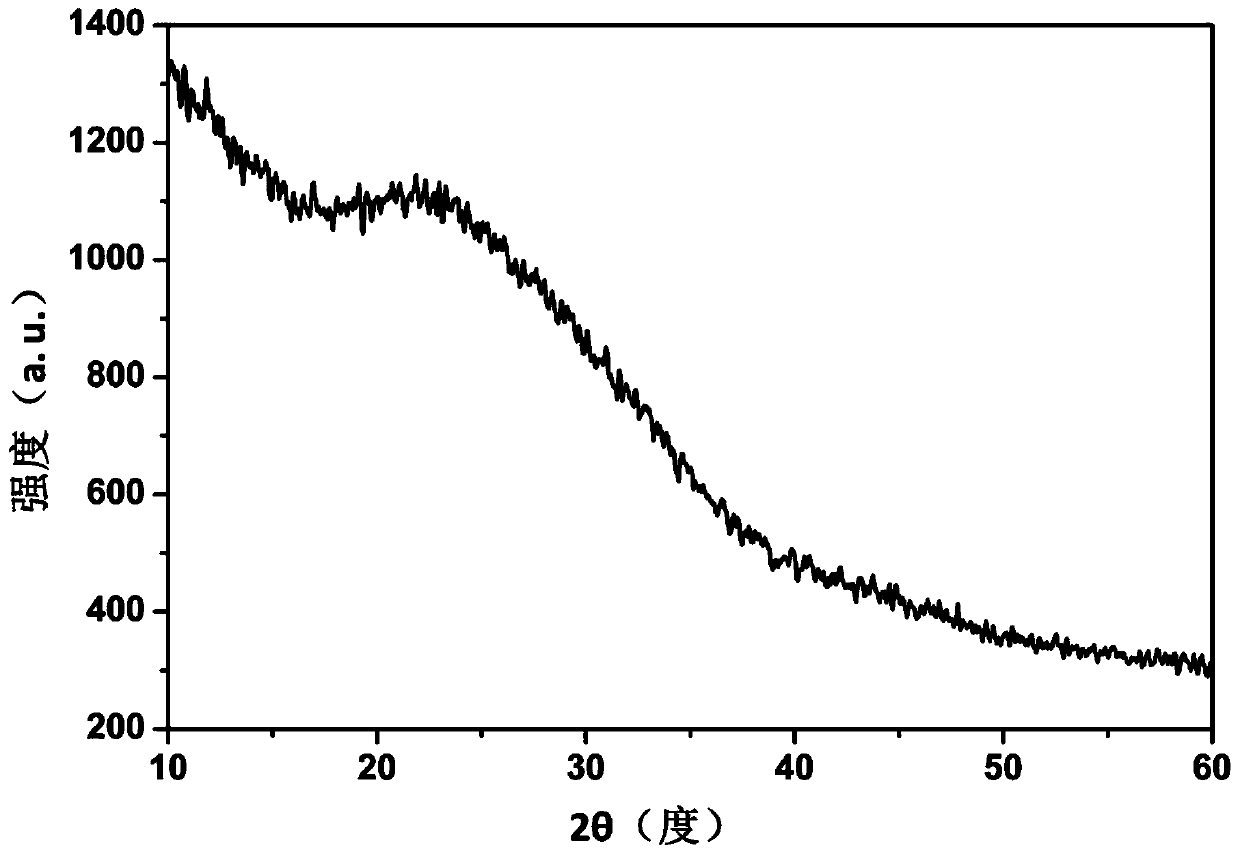

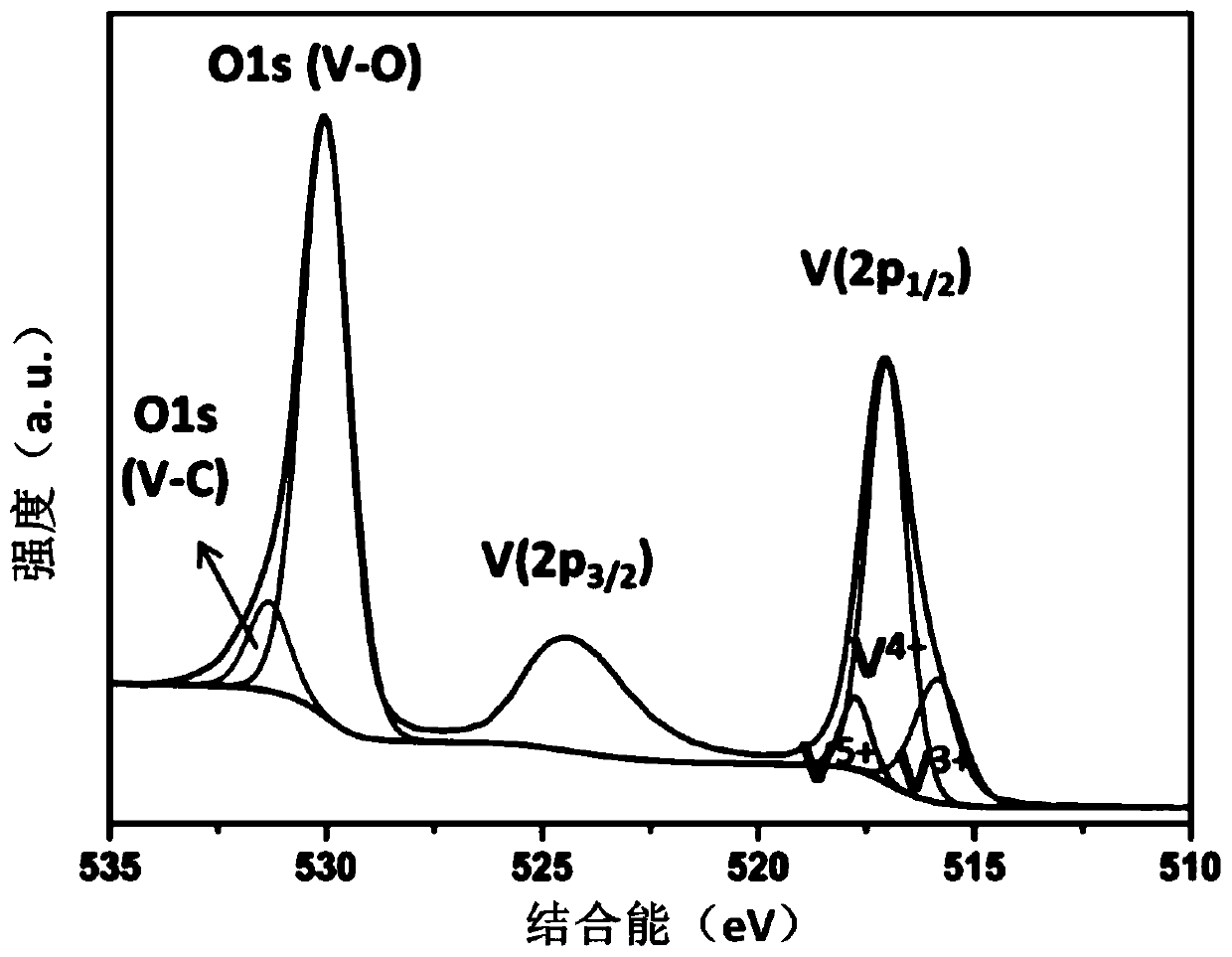

A vanadium dioxide and thin film technology, applied in the field of vanadium dioxide thin film preparation, can solve the problems of difficulty in ensuring thickness uniformity and accuracy, poor thin film thickness uniformity and controllability, unfriendly vanadium dioxide thin film environment, and the like, Achieve the effects of precise and controllable film thickness, good phase unity, and low film surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides a kind of preparation method of vanadium dioxide thin film, and this method specifically comprises the following steps:

[0045] Step 1: Preparation of vanadium oxide film by atomic layer deposition

[0046] (1) Place the cleaned glass slide in the atomic layer deposition reaction chamber.

[0047] (2) Start the vacuum system of the atomic layer deposition equipment to evacuate the atomic layer deposition reaction chamber to make it at 1Torr; start the temperature control system to heat different parts of the atomic layer deposition system, so that the triisopropoxyvanadyl precursor and injection The temperature of the channel is 50°C, the temperature of the deionized water precursor storage tank and the injection channel is 25°C, the inlet temperature of the atomic layer deposition system is 80°C, the temperature of the reaction chamber is 150°C, and the outlet temperature of the atomic layer deposition system is 120°C; start the flow T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com