High-temperature-resistant long-service-life aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and electrolytic capacitors, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve problems such as electrolyte leakage, capacitor life failure, and capacitor failure, so as to improve the guaranteed life, improve temperature resistance, and improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

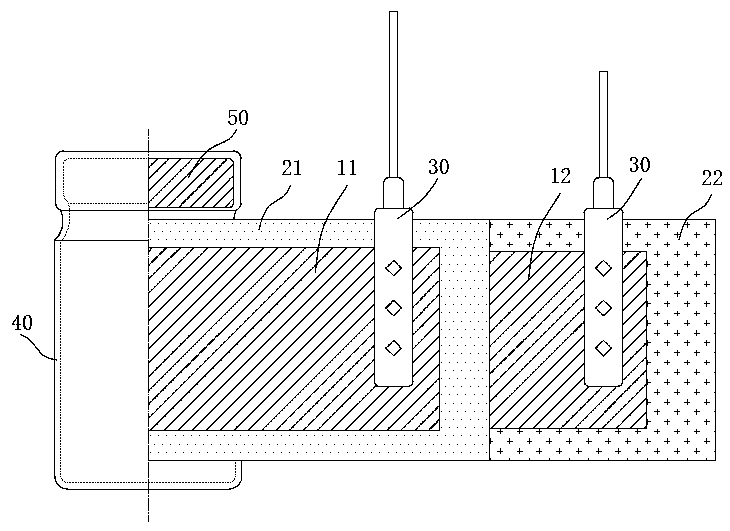

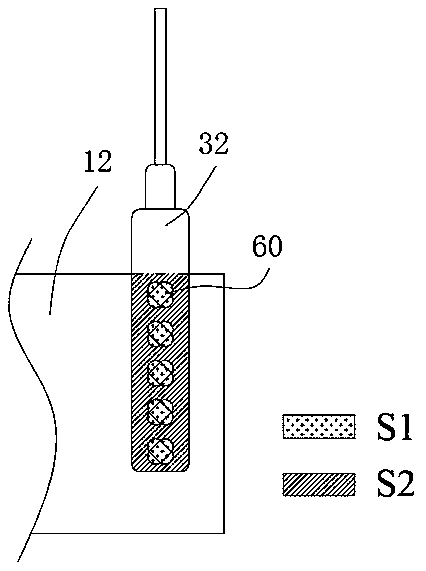

[0024] Such as figure 1 As shown, the present invention provides an aluminum electrolytic capacitor with high temperature resistance and long life. The aluminum electrolytic capacitor includes: a core package, a casing 40 arranged outside the core package, and glue covering the core package for sealing the casing 40 50 grains. The core pack includes anode foil 11 , cathode foil 12 , and electrolytic paper interposed between the anode foil 11 and the cathode foil 12 , laminated together with the anode foil 11 and the cathode foil 12 and wound into a core pack. Electrolytic paper can be designed with double or four layers. The anode foil 11 is connected with a positive lead pin 30 , and the anode foil 11 is connected with a negative lead pin 30 . Electrolyte is adsorbed in the core pack. The anode foil 11 and the cathode foil 12 are preferably aluminum foils. The positive electrode guide pin 30 and the negative electrode guide pin 30 are preferably aluminum guide pins.

[0...

specific Embodiment 1

[0036] 1) Solvent: 57.8% hexanediol;

[0037] 2) Solute: 15% ammonium hydrogen azelate, 5% ammonium dodecanoate, 3% diammonium hydrogen citrate, 7% ammonium isosebacate;

[0038] 3) Additives: 5% ammonium p-nitrobenzoate, 3% p-nitrophenol, 0.8% monobutyl phosphate, 0.8% ammonium hypophosphite, 1.0% nano-silica, 0.5% poly Ethylene oxide ether, 0.6% 8-hydroxyquinoline, 0.5% polymeric borate;

specific Embodiment 2

[0040] 1) Solvent: 40% hexanediol;

[0041] 2) Solute: 17% ammonium hydrogen azelate, 8% ammonium dodecanoate, 4% diammonium hydrogen citrate, 10% ammonium isosebacate;

[0042] 3) Additives: 8% ammonium p-nitrobenzoate, 5% p-nitrophenol, 2.0% monobutyl phosphate, 1.5% ammonium hypophosphite, 1.5% nano-silica, 1.0% poly Ethylene oxide ether, 1.0% 8-hydroxyquinoline, 1.0% polymeric borate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com