Near-infrared long-afterglow luminescent material as well as preparation method and application thereof

A technology of luminescent materials and external length, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high cost, and achieve the effect of low cost, not easy to absorb moisture, and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In addition, the present application also provides a preparation method for the above-mentioned near-infrared long-lasting luminescent material, which includes the following steps:

[0035] S1. Weigh the raw materials.

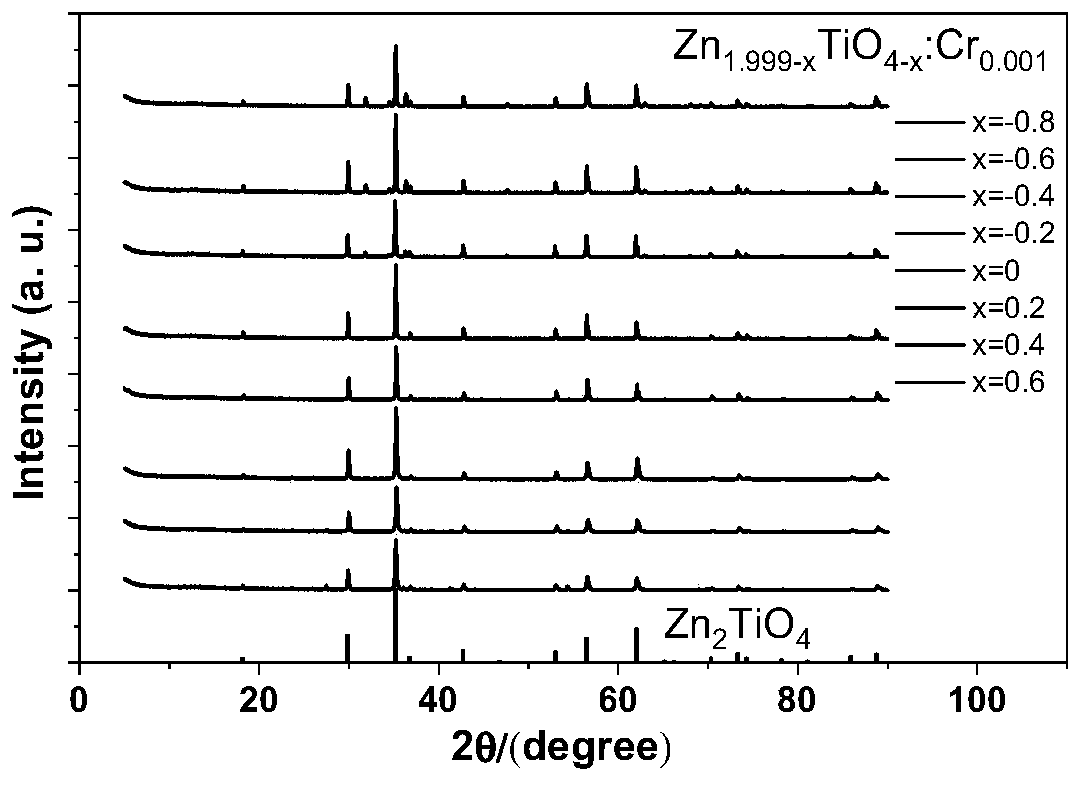

[0036] Weigh the raw material according to the following chemical composition expression, Zn 2–x–y TiO 4–x :Cr y , where -0.6≤x≤0.6; 0<y≤0.1, the raw materials include zinc-containing compounds, titanium-containing compounds and chromium-containing compounds. Wherein, the zinc-containing compound includes one or both of zinc oxide and zinc carbonate; the titanium-containing compound includes titanium dioxide; the chromium-containing compound includes one or more of chromium trioxide, chromium nitrate nonahydrate and chromium sulfate hexahydrate .

[0037] Grind the accurately weighed raw materials evenly in an ethanol solvent, specifically, grind the raw materials in an agate mortar or ball mill for 15-30 min. Grinding can crush the raw materials a...

Embodiment 1

[0045] Weigh zinc oxide (ZnO) 1.6265g, titanium dioxide (TiO 2 ) 0.7987g, chromium trioxide (Cr 2 o 3 ) 0.0015g and 5% boric acid (H 3 BO 3 ) 0.12g as a flux, put it in an agate mortar and grind it in an ethanol solvent for 20 minutes, mix it evenly, put it into a corundum crucible, put the corundum crucible into a high-temperature furnace, and roast it at a high temperature in an air atmosphere. The specific heating procedure is as follows : It takes 5 hours to raise the temperature from room temperature to 1500°C, keep the temperature for 5 hours, and then naturally cool to room temperature. The sample is taken out and ground to obtain the product, and its chemical composition expression is: Zn 1.999 TiO 4 :Cr 0.001 .

Embodiment 2

[0047] Weigh zinc oxide (ZnO) 1.4637g, titanium dioxide (TiO 2 ) 0.7987g, chromium trioxide (Cr 2 o 3 ) 0.0015g and 5% boric acid (H 3 BO 3 ) 0.12g as a flux, put it in an agate mortar and grind it in an ethanol solvent for 20 minutes and mix it evenly, then put it into a corundum crucible, put the corundum crucible into a high-temperature furnace and roast it at a high temperature in an air atmosphere. The specific heating procedure is as follows : It takes 5 hours to raise the temperature from room temperature to 1500°C, keep the temperature for 5 hours, and then naturally cool to room temperature. The sample is taken out and ground to obtain the product, and its chemical composition expression is: Zn 1.799 TiO 3.8 :Cr 0.001 .

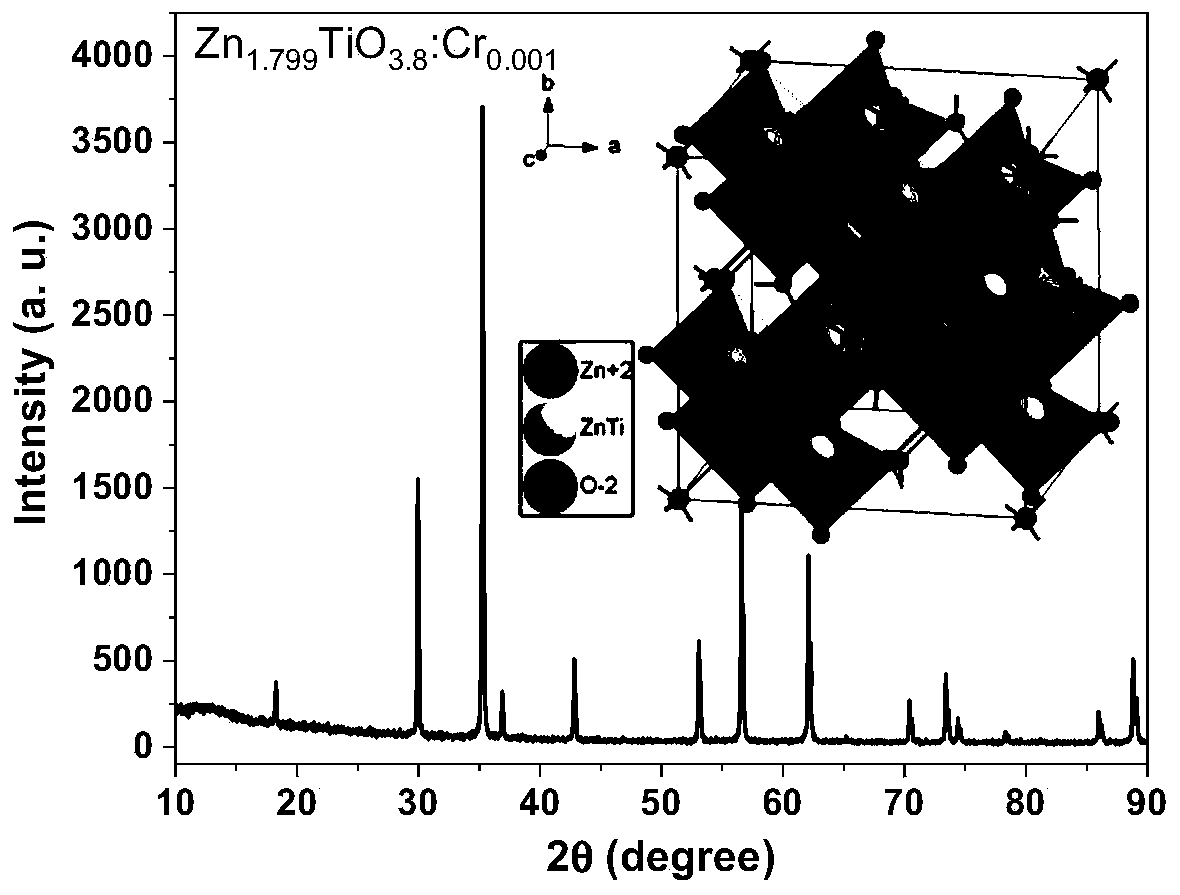

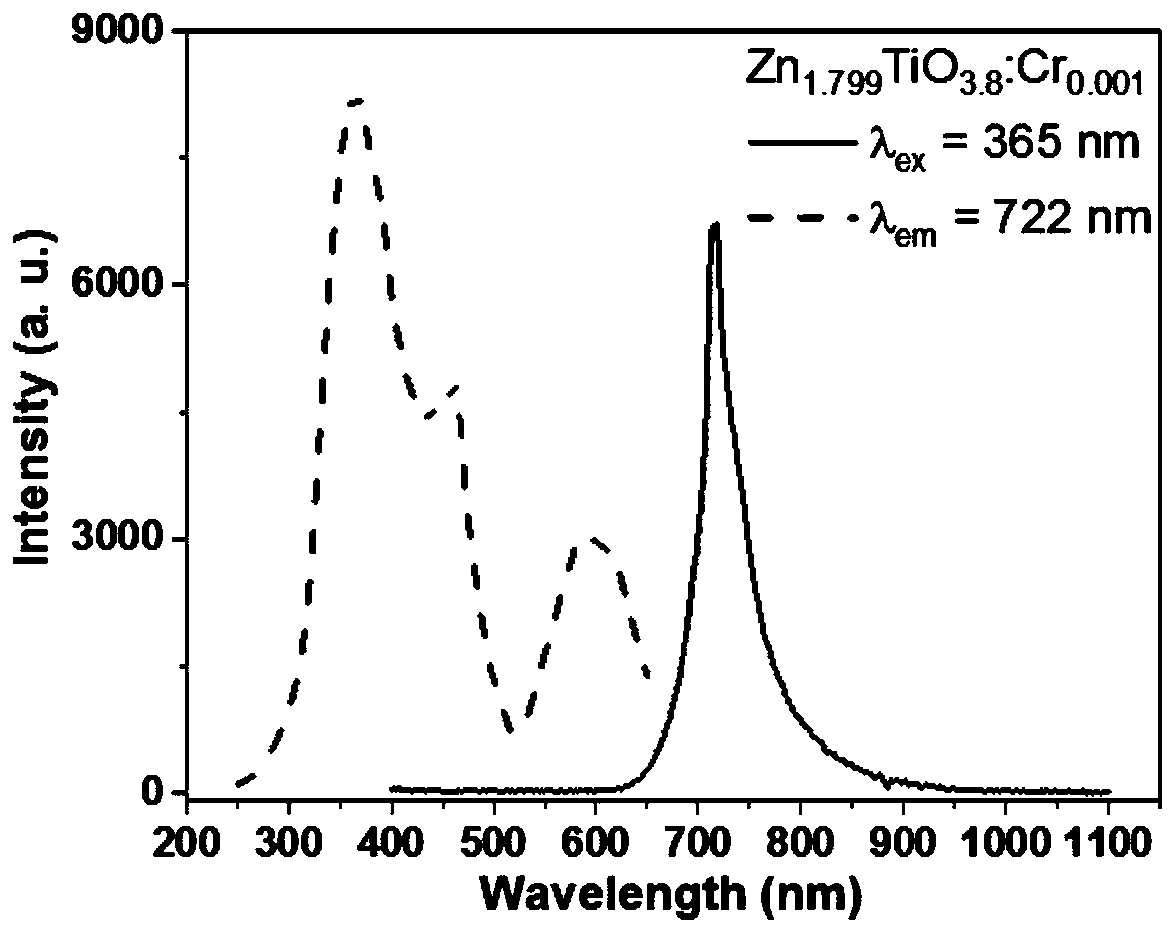

[0048] from figure 1 It can be seen that the XRD of the sample is consistent with that of Zn 2 TiO 4 The standard cards match, thus proving that the synthesized material has an inverse spinel structure, and the schematic diagram of the unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com