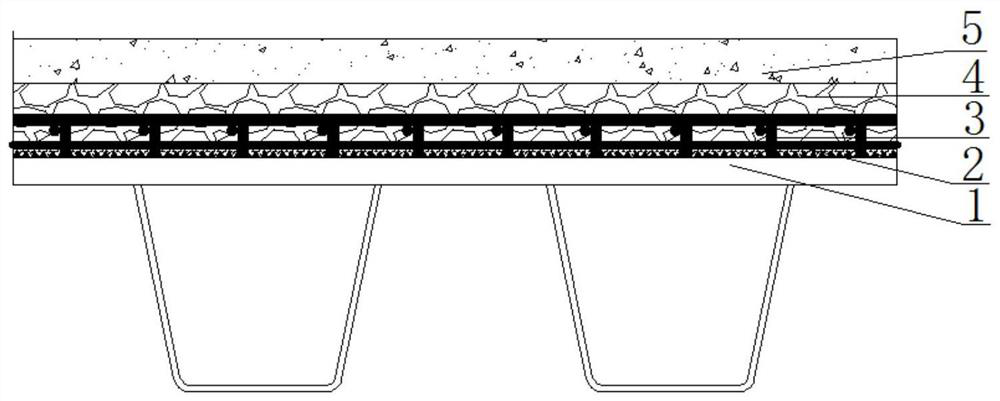

A resin combined ultra-high performance concrete pavement structure and construction method

An ultra-high-performance concrete technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of steel bridge deck safety hazards, burrs, maintenance and repair effects, etc., to eliminate damage, good toughness and durability, Effect of improving bending cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The construction method of resin combined ultra-high performance concrete pavement structure, calculated according to the parts by mass, includes the following steps:

[0056] S1. Carry out sandblasting and derusting cleaning treatment on the steel panel to obtain a steel panel base layer with a cleanliness of Sa2.5 or higher and a roughness of 60-150 μm;

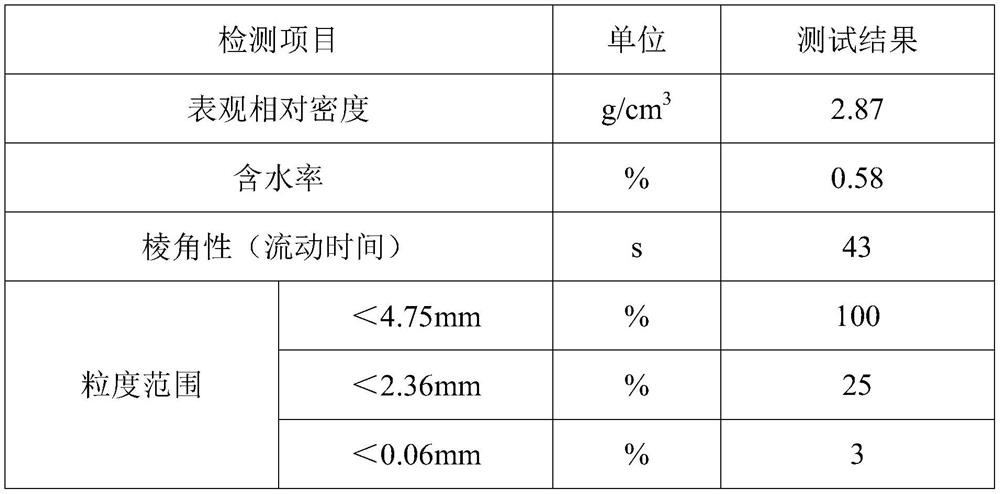

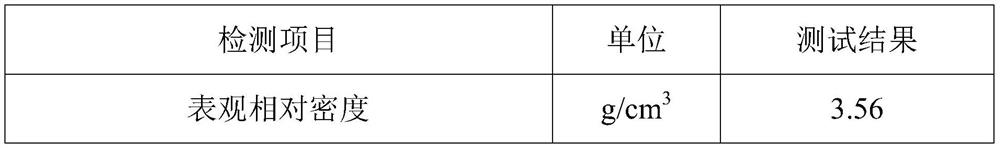

[0057] S2. Prepare high-tough resin by 65 parts of bisphenol epoxy resin, 16 parts of polyamide curing agent, 10 parts of butyl glycidyl ether reactive diluent, 5 parts of nitrile rubber toughening agent and 5 parts of quartz powder reinforcing agent, steel Within 2 hours after the sandblasting and derusting of the panel, coat high-toughness resin on the surface of the steel panel base, spread 3-5mm single-size basalt gravel, and bond shear nails synchronously; the coating amount of high-toughness resin adhesive is 1kg / m 2 , single-size crushed stone spreading rate 3kg / m 2 ;The shear nails are arranged on the upper ...

Embodiment 2

[0068] The resin-combined ultra-high-performance concrete pavement construction method, calculated according to the parts by mass, includes the following steps:

[0069] S1. Carry out sandblasting and derusting cleaning treatment on the steel panel to obtain a steel panel base layer with a cleanliness of Sa2.5 or higher and a roughness of 60-150 μm;

[0070] S2. Prepare high-tough resin by 68 parts of bisphenol epoxy resin, 12 parts of butyl glycidyl ether reactive diluent, 14 parts of polyamide curing agent, 3 parts of nitrile rubber toughening agent and 3 parts of quartz powder reinforcing agent, steel Coating high-toughness resin on the base surface of the steel panel within 2 hours after the sandblasting and derusting of the panel, spreading 3-5mm single-size crushed stone, and synchronously bonding shear nails; the coating amount of high-toughness resin adhesive is 1.8kg / m 2 , single-size crushed stone spreading rate 4kg / m 2 ;The shear nails are arranged on the upper par...

Embodiment 3

[0082] The resin-combined ultra-high-performance concrete pavement construction method, calculated according to the parts by mass, includes the following steps:

[0083] S1. Carry out sandblasting and derusting cleaning treatment on the steel panel to obtain a steel panel base layer with a cleanliness of Sa2.5 or higher and a roughness of 60-150 μm;

[0084] S2. Prepare high-tough resin by 70 parts of bisphenol epoxy resin, 15 parts of butyl glycidyl ether reactive diluent, 16 parts of polyamide curing agent, 2 parts of nitrile rubber toughening agent and 2 parts of quartz powder reinforcing agent, steel Coating high-toughness resin on the base surface of the steel panel within 2 hours after the sandblasting and derusting of the panel, spreading 3-5mm single-grain gravel, and synchronously bonding shear nails; the coating amount of high-toughness resin adhesive is 1.5kg / m 2 , single-size crushed stone spreading rate kg / m 2 ;The shear nails are arranged on the upper part of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com