Recycling method for phosphorus in phosphorus-containing waste

A recycling and waste technology, applied in chemical instruments and methods, phosphorus compounds, phosphates, etc., can solve the problems of high cost, difficult industrial application, and no mention of inorganic phosphate reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

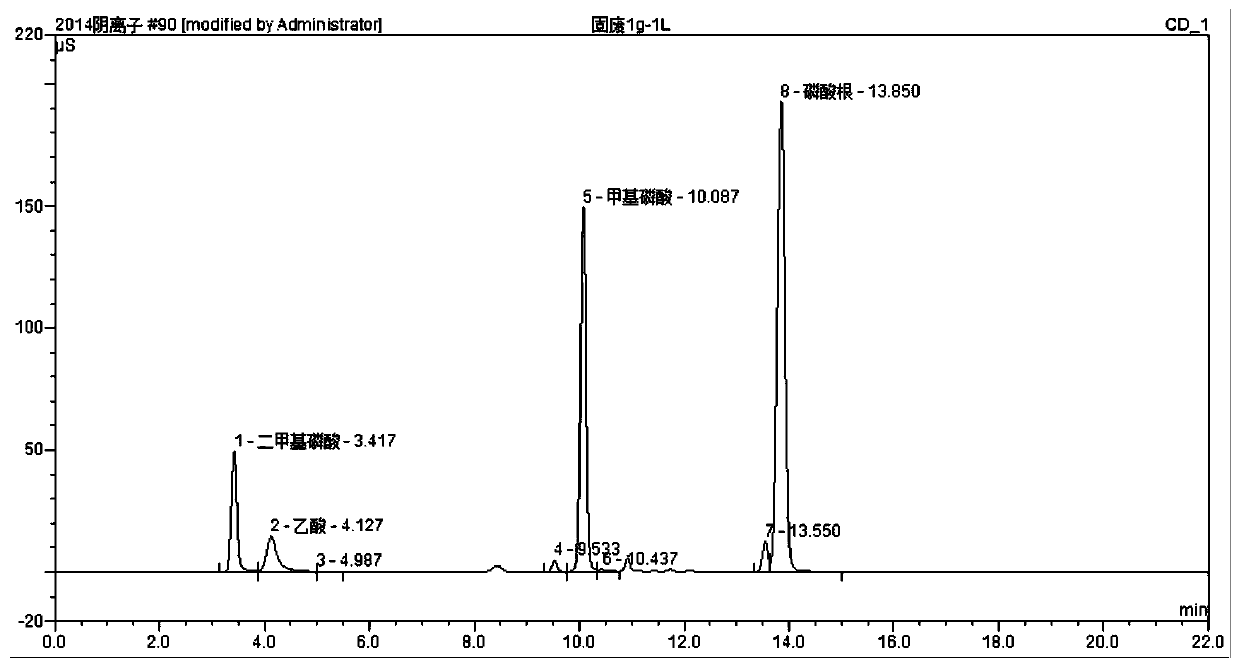

[0041] In the experiment, the industrial untreated acetic acid cracking method was used to prepare the process condensate produced by the acetic anhydride process. After ion chromatography analysis, the total phosphorus in the water was 1200mg / L, which contained 40% orthophosphorus and 60% organic phosphorus.

[0042] The above waste water is concentrated by an acid-resistant nanofiltration membrane concentration device, so that the total phosphorus content reaches 60,000 mg / L, and then cooled and crystallized at 35°C, filtered and washed to obtain an inorganic phosphate filter cake. The filtrate containing organophosphorus obtained by filtering is passed through O in the fixed bed reactor. 2 , at 400° C., reacted for 15 minutes under the action of a catalyst, wherein the organic phosphorus was converted into an inorganic phosphate mixture, and then returned to the aforementioned step (1) to continue to concentrate through the acid-resistant nanofiltration membrane. Dissolve, ...

Embodiment 2

[0044] In the experiment, the industrial untreated acetic acid cracking method was used to prepare the process condensate produced by the acetic anhydride process. According to ion chromatography analysis, the total phosphorus in the water was 1000mg / L, which contained 60% orthophosphorus and 40% organic phosphorus.

[0045] The above waste water is concentrated by a mechanical vapor recompression (MVR) evaporator, and the total phosphorus content reaches 80,000 mg / L. Then, it is cooled and crystallized at 30° C., press-filtered, and washed to obtain an inorganic phosphate filter cake. The organophosphorus-containing filtrate obtained by pressure filtration was added with H in a stirred tank reactor at 40°C 2 o 2, and reacted for 70 minutes under the action of a catalyst, wherein the organophosphorus was converted into a mixed solution of inorganic phosphate, and then returned to the aforementioned step (1) for concentration. The obtained inorganic phosphate is dissolved, fil...

Embodiment 3

[0047] In the experiment, the industrial untreated acetic acid cracking method was used to prepare the process condensate produced by the acetic anhydride process. After ion chromatography analysis, the total phosphorus in the water was 100mg / L, which contained 65% orthophosphorus and 35% organic phosphorus.

[0048] The above waste water is concentrated by a five-stage flash evaporation device, and the total phosphorus content reaches 60,000 mg / L. Then, it is cooled and crystallized at 15°C, centrifuged and washed to obtain an inorganic phosphate filter cake. The filtrate containing organophosphorus obtained by centrifugation is passed into air at 120°C in a tower reactor, and reacted for 120min under the action of a catalyst, wherein the organophosphorus is converted into an inorganic phosphate mixture, and then returns to the previous step (1 ) for concentration. The obtained inorganic phosphate is dissolved, filtered, recrystallized, washed to obtain a higher purity inorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com