Shortcut nitrification-anaerobic ammonia oxidation technology for efficiently treating low-carbon and high-ammonia-nitrogen wastewater

An anaerobic ammonia oxidation and short-range nitrification technology, which is applied in the field of sewage treatment, can solve the problems of low carbon and high ammonia nitrogen wastewater and other problems, and achieve the effects of low treatment cost, complete denitrification and controllable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

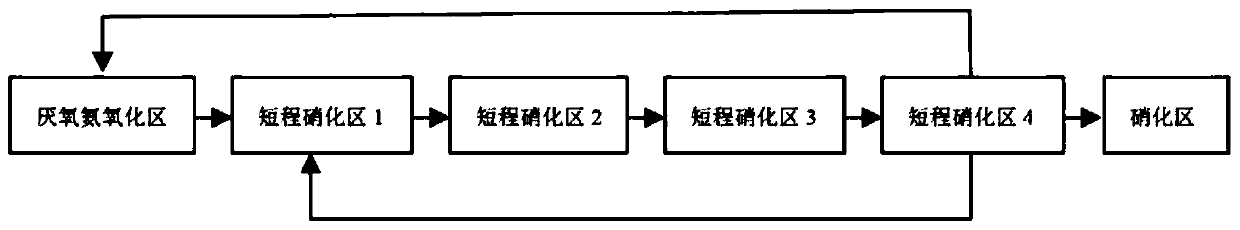

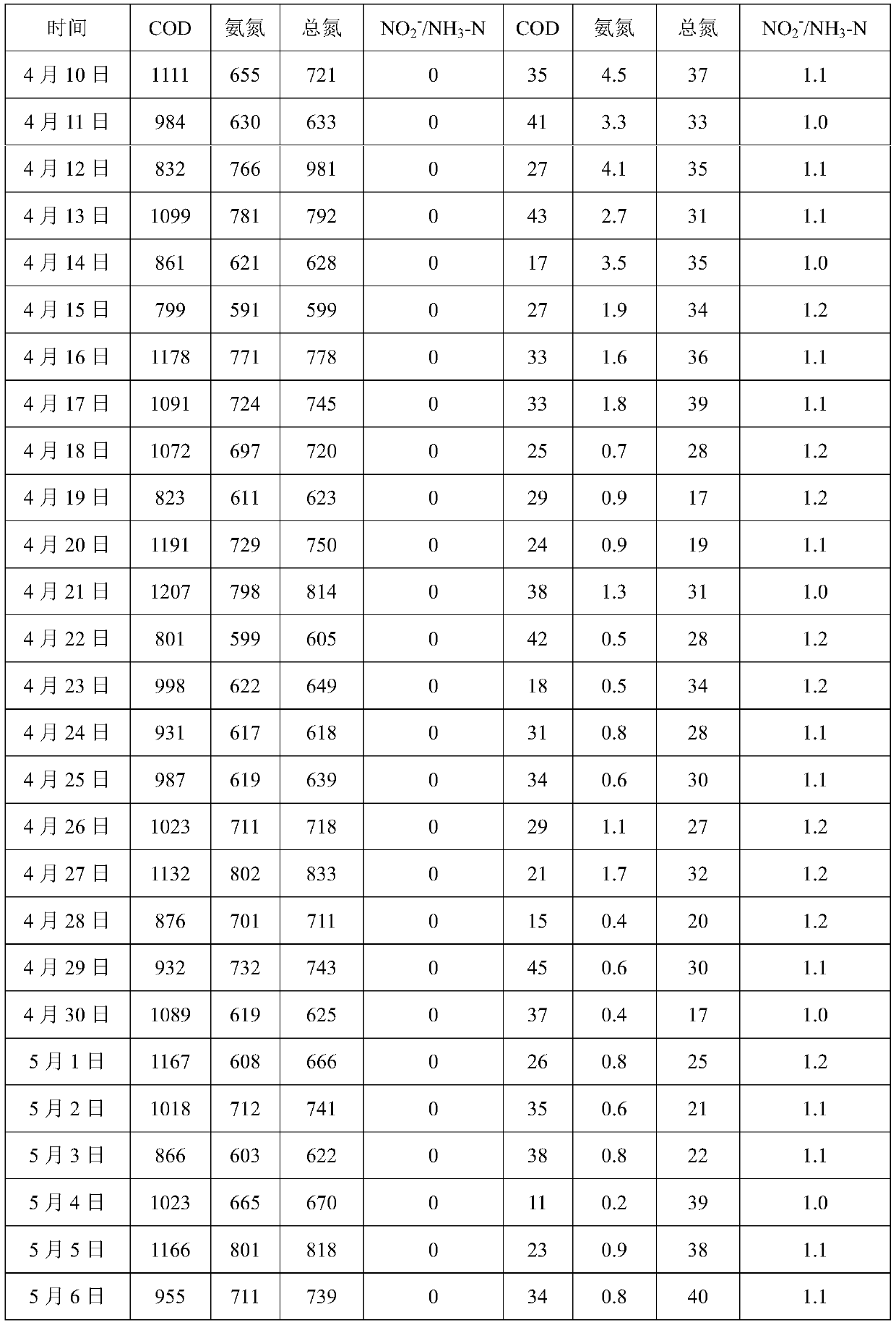

[0040] like figure 1 As shown, it is a schematic flow chart of the sewage treatment process for treating low-carbon high-ammonia-nitrogen wastewater in this embodiment. First, the low-carbon and high-ammonia-nitrogen wastewater enters the anammox zone for anammox, and then enters the short-cut nitrification zone 1-4 in turn through the overflow method. A part of the ammonia nitrogen in the wastewater will be converted into nitrite nitrogen in the facultative zone because of the short-cut nitrification The conditions of zones 1-4 are different, and the nitrite nitrogen in the short-range nitrification zone 4 will be higher, which is harmful to the microorganisms in the water body. Therefore, part of the short-range nitrification zone 4 is returned to the short-range nitrification zone 1, and the other part of the wastewater is returned to the anammox. Zone re-reacts until the ratio of nitrite nitrogen to ammonia nitrogen in the short-range nitrification zone 4 is roughly 1.0, a...

Embodiment 2

[0050] The treatment device is the same as in Example 1, wherein the packing density in the anaerobic ammonium oxidation zone is 0.985g / cm 3 , the filling rate is 30%; the packing density of each short-range nitrification zone is 0.978g / cm 3 , the filling rate is 20%; the packing density in the nitrification zone is 0.97g / cm 3 , fill rate 30%. Control the dissolved oxygen concentration in the anaerobic ammonium oxidation zone to 0.1mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 1 to 0.3mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 2 to 0.5mg / L, and the dissolved oxygen concentration in the short-cut nitrification zone 3 The dissolved oxygen concentration in the short-cut nitrification zone 4 is 1.0mg / L, and the dissolved oxygen concentration in the nitrification zone is 3.0mg / L.

[0051] The anaerobic ammonium oxidation zone, each short-range nitrification zone, and the nitrification zone are inoculated with activa...

Embodiment 3

[0058] The treatment device is the same as in Example 1, wherein the packing density in the anaerobic ammonium oxidation zone is 0.99g / cm 3 , the filling rate is 30%; the packing density of each short-range nitrification zone is 0.98g / cm 3 , the filling rate is 20%; the packing density in the nitrification zone is 0.99g / cm 3 , fill rate 30%. Control the dissolved oxygen concentration in the anammox zone to 0.01mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 1 to 0.3mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 2 to 0.4mg / L, and the dissolved oxygen concentration in the short-cut nitrification zone 3 The dissolved oxygen concentration in the short-cut nitrification zone 4 is 0.7mg / L, and the dissolved oxygen concentration in the nitrification zone is 2mg / L.

[0059] The anaerobic ammonium oxidation zone, each short-range nitrification zone, and the nitrification zone are inoculated with activated sludge, and the slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com