Silane crosslinked flame-retardant semiconductive polyolefin sheathing material, preparation method therefor and application of sheathing material

A polyolefin sheath and silane cross-linking technology, which is applied in the field of coal mines, can solve the problems of difficult pre-cross-linking, rough extrusion surface, fire gas, etc., and achieve excellent mechanical properties, smooth extrusion surface and good electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

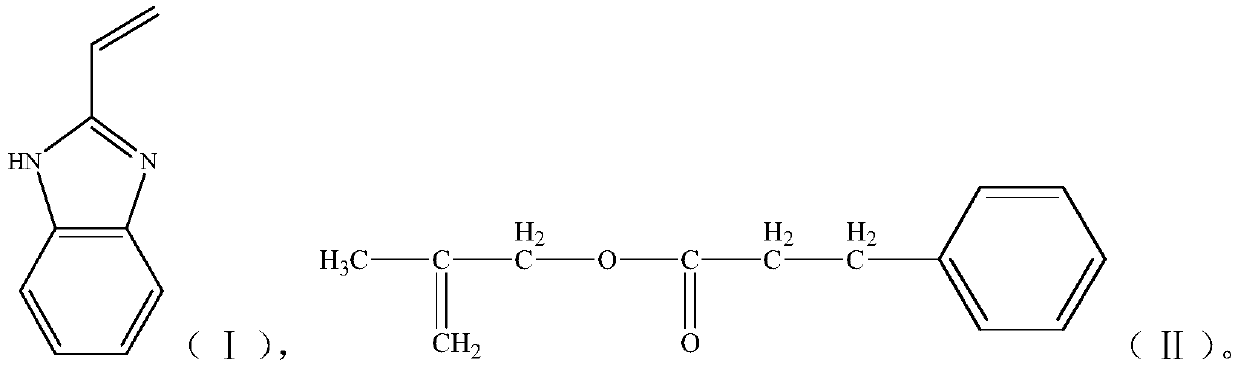

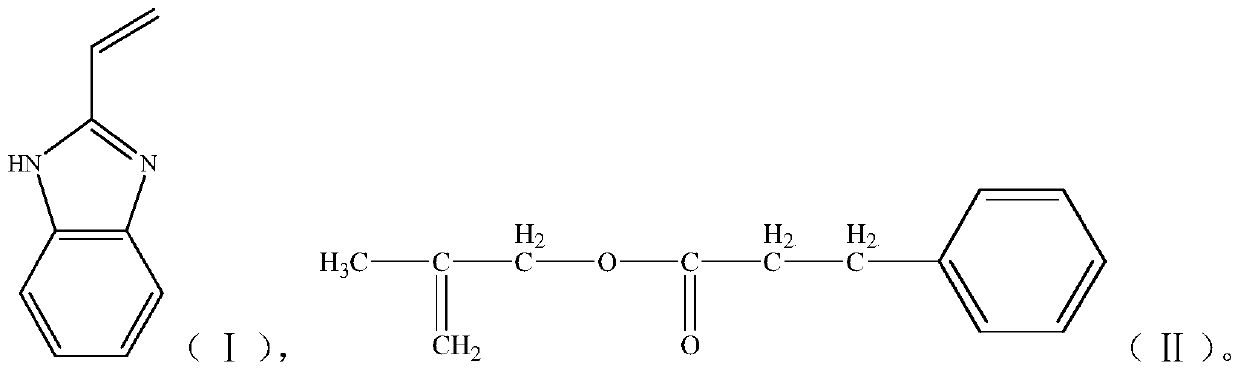

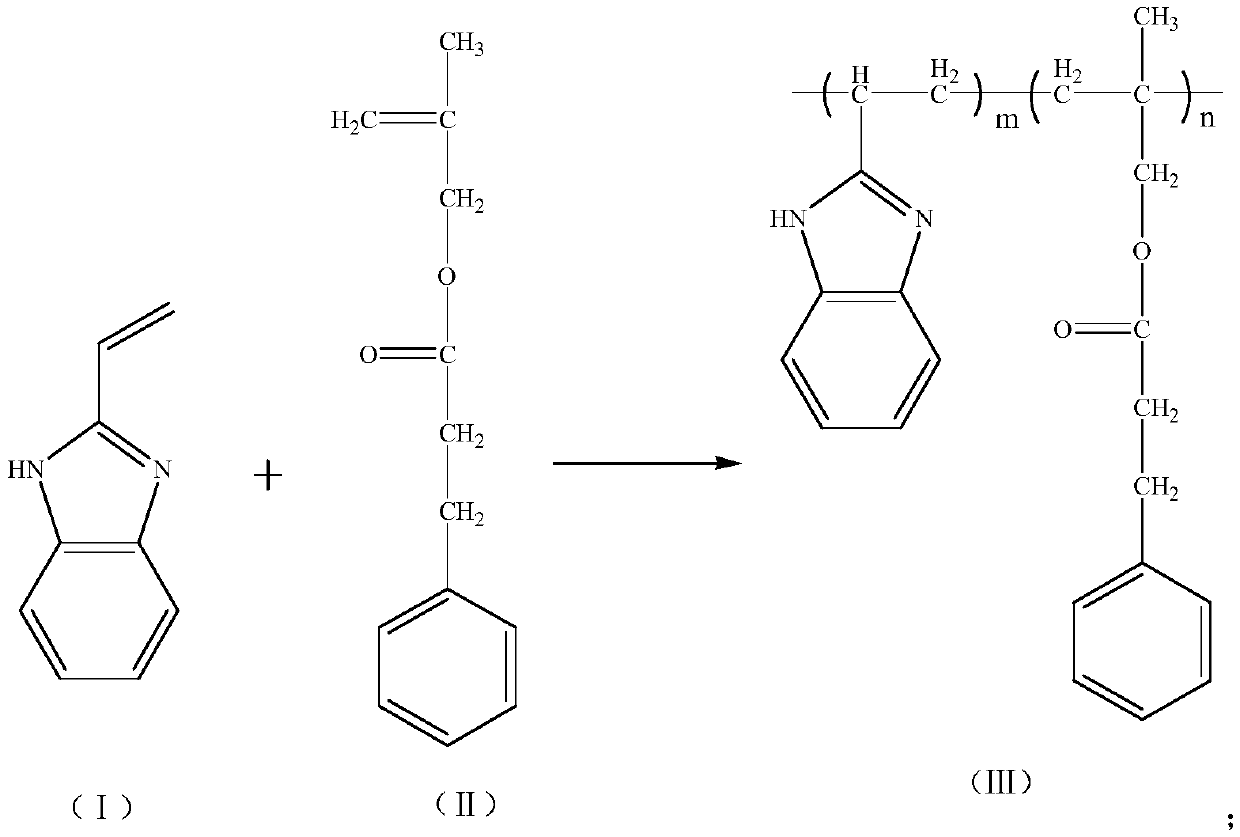

[0045] These embodiments provide a silane crosslinked flame-retardant semi-conductive polyolefin sheath material, the raw materials and composition of which are shown in Table 1 below.

[0046] Table 1

[0047]

[0048]

[0049] Among them, the feed mass ratio of material A to material B is 5:1.

[0050] The preparation method is as follows: Preparation of material A: mix linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene-octene copolymer to obtain resin base material, mix vinyl-containing silane, initiator and anti-pre-crosslinking agent The silane grafting liquid is obtained, and then the remaining raw materials of the A material are mixed to obtain auxiliary materials, which are fed by a reciprocating single-screw buss machine, and are melted and co-extruded to be grafted; wherein, the silane grafting liquid is in the screw The end of the extruder is injected; wherein the length-to-diameter ratio of the reciprocating single-screw buss machine is ≥40:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

| Oxygen index | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com