A double-electricity highly dispersed graphene nano-hybrid material, preparation and application

A nano-hybrid material, graphene technology, applied in the fields of chemical industry, chemistry, biology, and energy, can solve the problems of high cost, singleness, and poor redispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

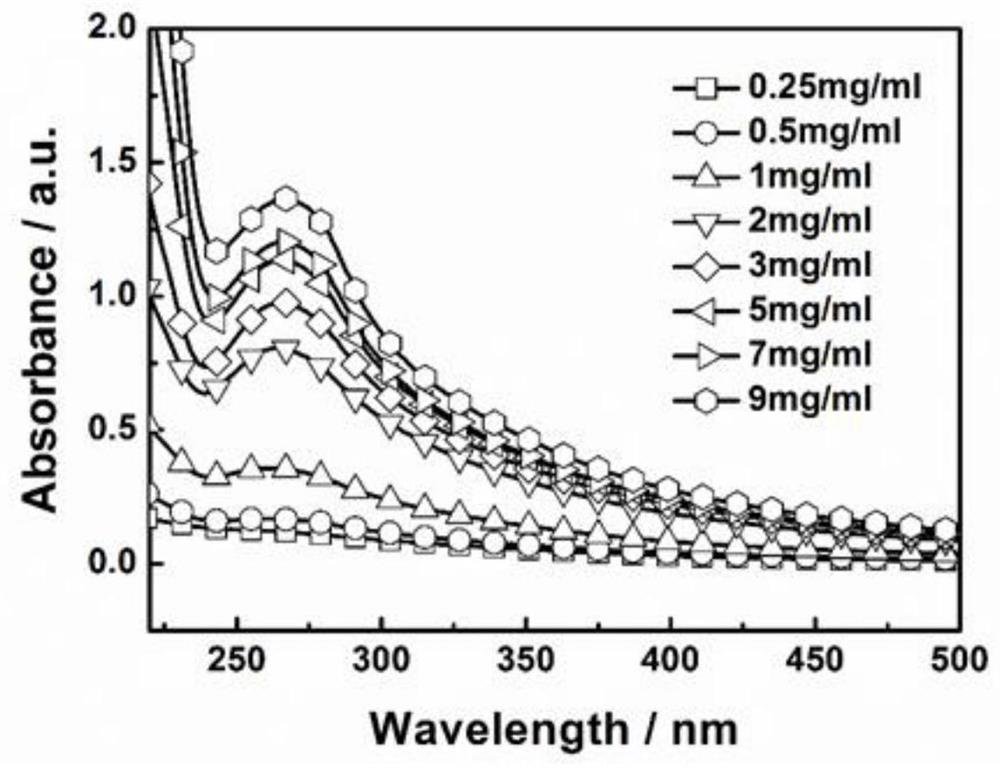

[0058] 1) Preparation of casein dispersion: Mix 10g casein and 85g deionized water, heat and stir at 50°C for 5h, then add 5g of 25% ammonia water, continue stirring at 50°C for 1h to dissolve casein, and obtain 10% casein Casein dispersion (ie 100mg / ml);

[0059] 2) Add the casein dispersion prepared in step 1) into a certain amount of deionized water and dilute to 1 mg / ml, and the pH is 10 at this time;

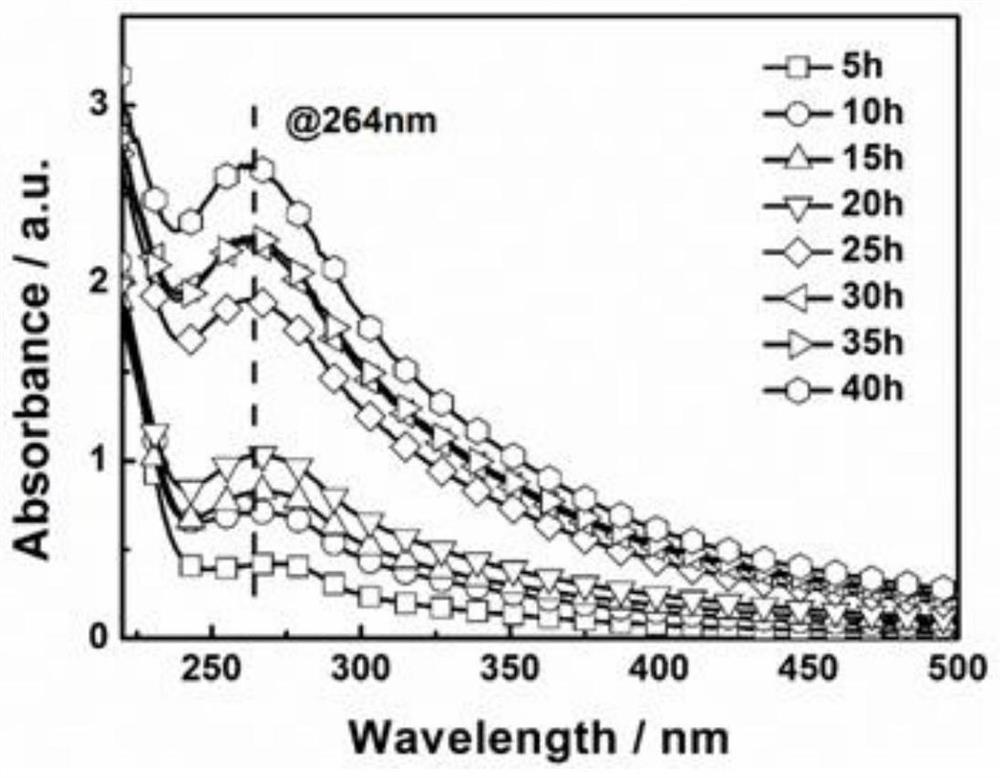

[0060] 300ml, 1mg / ml casein dispersion and 3g graphite were mixed, added to a 500ml stainless steel ball mill jar, ball milled at 185r for 30h, then the mixed solution was taken out, and centrifuged to obtain a double-charged graphene / casein nano-hybrid material; The yield of prepared graphene was 4.6%, and the graphene concentration was a dispersion of graphene / casein hybrid material of 0.46 mg / ml. The solid film prepared by drying the double-electric high-dispersion graphene nano-hybrid material is redispersed into water with a concentration of more than 2%; the thicknes...

Embodiment 2

[0062] Same as Example 1, except that 300ml, 1mg / ml casein dispersion and 3g graphite were mixed, added to a 500ml stainless steel ball mill jar, and ball milled at 185r for 5h. The yield of prepared graphene was 0.87%, and the concentration of graphene was 0.087mg / ml. The solid film prepared by drying the double-electric high-dispersion graphene nano-hybrid material is redispersed into water with a concentration of more than 2%; the thickness of the graphene sheet of the double-electric high-dispersion graphene nano-hybrid material is 1-20nm , the sheet size is 300nm-20μm.

Embodiment 3

[0064] Same as Example 1, except that 300ml, 1mg / ml casein dispersion and 3g graphite were mixed, added to a 500ml stainless steel ball mill jar, and ball milled at 185r for 10h. The yield of prepared graphene was 1.5%, and the concentration of graphene was 0.15 mg / ml. The solid film prepared by drying the double-electric high-dispersion graphene nano-hybrid material is redispersed into water with a concentration of more than 2%; the thickness of the graphene sheet of the double-electric high-dispersion graphene nano-hybrid material is 1-20nm , the sheet size is 300nm-20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com