Preparation method and application of double-braid polymer surfactant containing long carbon chains

A technology of surfactants and polymers, applied in the field of double-braided polymer surfactants and their preparation, can solve the problems of difficult to achieve viscosity reduction, difficult to form, and unable to reduce the viscosity of heavy oil, and achieve an excellent interface Effects of activity, storage convenience, excellent permeability and wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

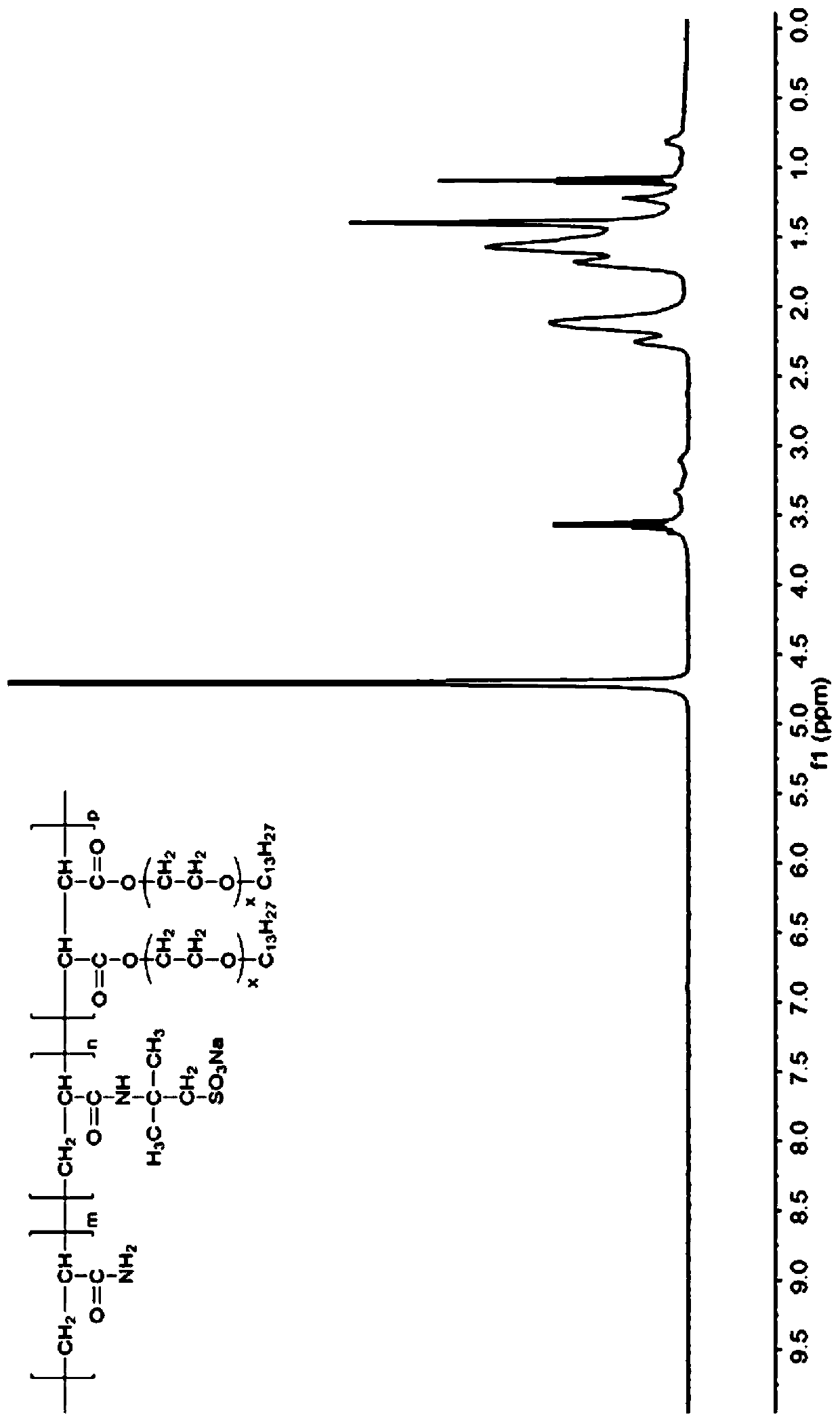

Method used

Image

Examples

Embodiment 1

[0063] (1) In a 250mL three-neck flask equipped with a thermometer, a magnetic stirrer, a water separator and a reflux condenser, isomeric tridecyl polyoxyethylene ether (20.0000g, 31.250 mmol), maleic anhydride (1.2258g, 12.501mmol), toluene (100mL); after stirring and dissolving, add p-toluenesulfonic acid (0.2547g, 1.479mmol), heat up to the reflux of the reaction solution, and control the reaction temperature to 120±5°C , After the reaction was refluxed for 5h, the heating was stopped and cooled.

[0064] (2) Pour the reaction solution in step (1) into a separatory funnel, wash it several times with 5wt% aqueous sodium bicarbonate solution and saturated saline to neutrality, dry with anhydrous sodium sulfate, and dry the solution After concentrating under reduced pressure, a yellow oil was obtained, which was diisomeric tridecyl polyoxyethylene ether maleic acid diester (I13C) containing 10 ethyleneoxy EO units. 10 MA) 14.25 g.

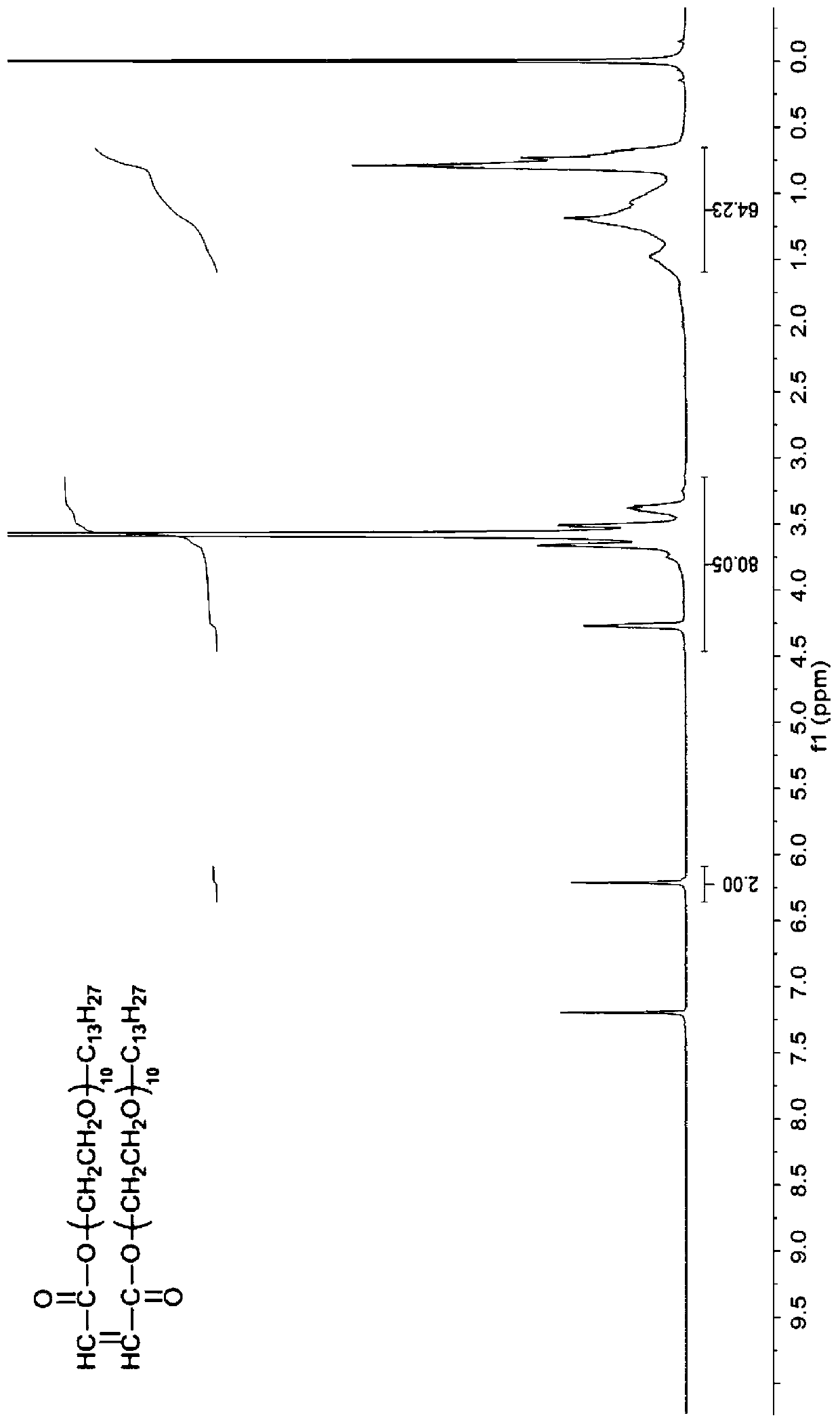

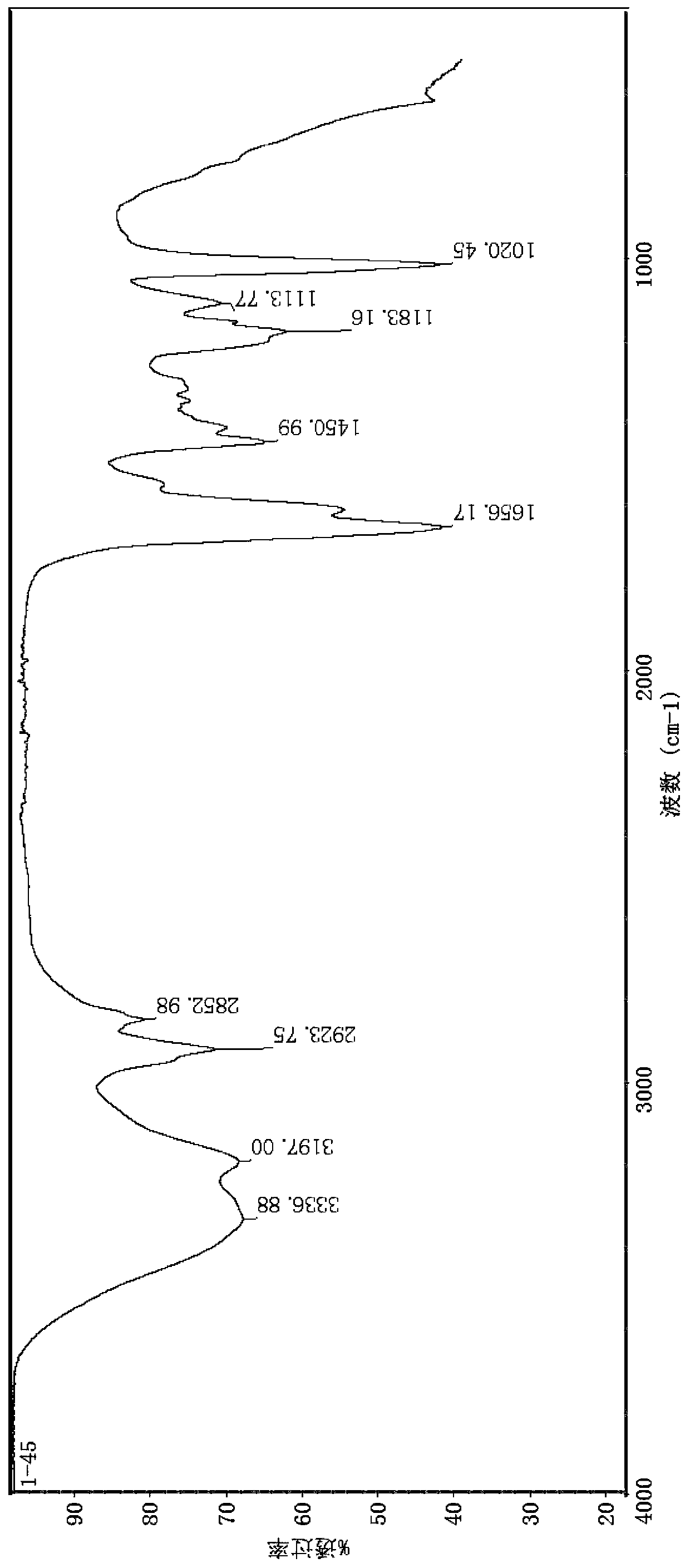

[0065] The proton nuclear magnetic resona...

Embodiment 2

[0068] The preparation method is the same as in Example 1, the difference is that in step (1), isomeric tridecyl polyoxyethylene ether (20.0000g, 23.225mmol) containing 15 ethyleneoxy EO units, Malay Anhydride (0.8133 g, 8.294 mmol) and p-toluenesulfonic acid (0.3743 g, 2.174 mmol).

[0069] The yellow oily product obtained was diisomeric tridecyl polyoxyethylene ether maleate diester (I13C) containing 15 ethyleneoxy EO units. 15 MA) 11.63 g.

[0070] H NMR spectrum ( 1 HNMR, 400MHz, CDCl 3 ) data are as follows: δ (ppm): 6.25 (2H, hydrogen-C on the double bond H =C H -),3.33-4.35(120H, for 30-OC H 2 C H 2 O-),0.5-1.70(54H, for alkyl hydrogen C 13 H 27 -).

[0071] Through proton nuclear magnetic resonance spectrum analysis, confirm that the product that obtains is the diisomeric tridecyl polyoxyethylene ether maleic acid diester (I13C containing 15 ethylene oxide EO units. 15 MA).

Embodiment 3

[0073] The preparation method is the same as in Example 1, the difference is that in step (1), isomeric tridecyl polyoxyethylene ether (20.0000g, 13.158mmol) containing 30 ethyleneoxy EO units, Malay Anhydride (0.5161 g, 5.263 mmol) and p-toluenesulfonic acid (0.3077 g, 1.787 mmol).

[0074] The yellow oily product obtained is diisomeric tridecyl polyoxyethylene ether maleate diester containing 30 ethyleneoxy EO units (I13C 30 MA) 13.16 g.

[0075] H NMR spectrum ( 1 HNMR, 400MHz, CDCl 3 ) data are as follows: δ (ppm): 6.24 (2H, hydrogen-C on the double bond H =C H -),3.31-4.35(240H, for 60-OC H 2 C H 2 O-),0.5-1.70(54H, for alkyl hydrogen C 13 H 27 -).

[0076] Through proton nuclear magnetic resonance spectrum analysis, confirm that the product that obtains is the diisomeric tridecyl polyoxyethylene ether maleic acid diester (I13C containing 30 ethylene oxide EO units. 30 MA).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com