Insulating high-strength nano composite material and preparation method thereof

A nano-composite material and high-strength technology, which is applied in the field of insulating high-strength nano-composite materials and its preparation, can solve the problems of insignificant improvement of thermal conductivity, inconspicuous improvement of thermal conductivity, uneven dispersion of graphene, etc., and achieve less preparation process, The effect of high thermal conductivity filler content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

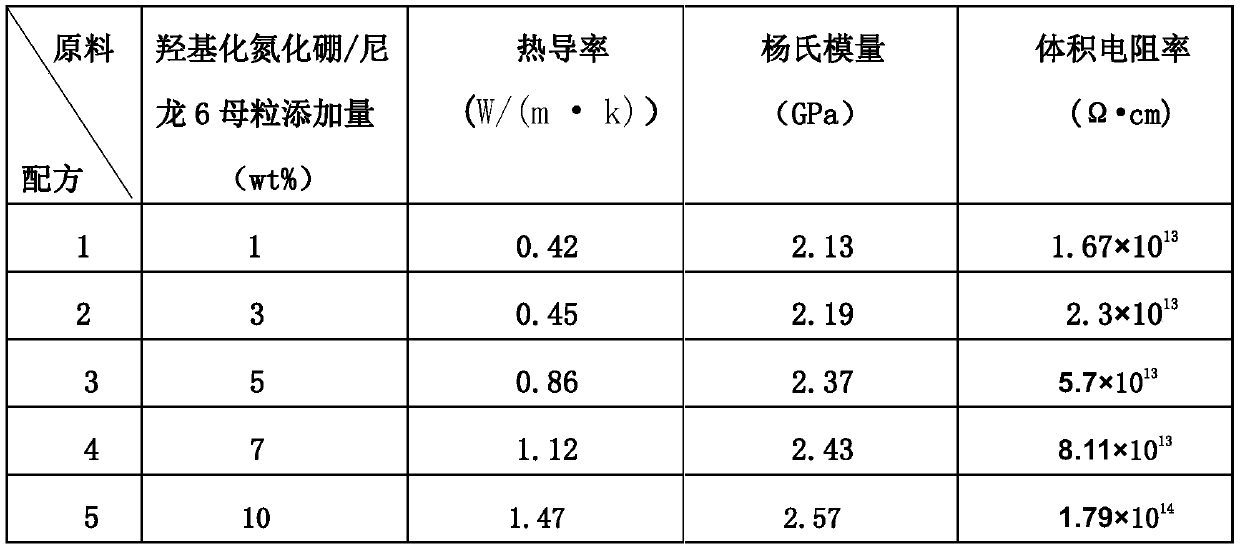

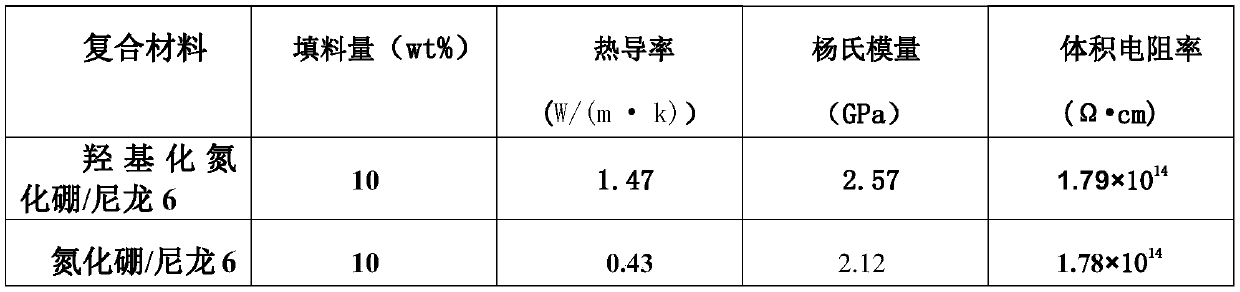

[0031] Embodiment 1: The insulating high-strength nanocomposite material provided by the embodiment of the present invention is made of the following raw materials, which are calculated in parts by weight:

[0032] 1) Hydroxylated boron nitride / nylon 6 masterbatch 1-10 parts

[0033] 2) Nylon 6 100 parts.

[0034] The hydroxylated boron nitride / nylon 6 masterbatch, in parts by weight, is composed of 50-70 parts of hydroxylated boron nitride, 20-45 parts of nylon 6 monomer, 1-5 parts of catalyst or initiator, It is prepared after premixing, prepolymerization, polymerization, discharging, granulation, washing and drying.

[0035] The nylon 6 is pure polyamide 6.

[0036] The hydroxylated boron nitride is obtained from hexagonal boron nitride with a particle size of 4 microns after tip ultrasonic exfoliation, with a particle size of 400 nanometers and a thickness of 5 nanometers.

[0037] The nylon 6 monomer is ε-caprolactam.

[0038] The catalyst or initiator is 6-aminocapro...

Embodiment 2

[0049] The insulating high-strength nano-composite material and its preparation method provided by the embodiment of the present invention are basically the same as the embodiment 1, the difference lies in:

[0050] Preparation of hydroxylated boron nitride:

[0051] Hydroxylated boron nitride nanosheets were prepared by solution exfoliation using cutting-edge ultrasonic technology. Disperse 1g of boron nitride powder in 100mL of 0.05wt% sodium cholate aqueous solution, and ultrasonically treat the tip in an ultrasonic pulverizer (600W, 25°C) for 10h to obtain 10mg·mL -1 Hydroxylated boron nitride nanosheets.

[0052] Preparation of hydroxylated boron nitride / nylon 6 nanocomposites:

[0053] 70 parts by weight of hydroxylated boron nitride, 27 parts by weight of ε-caprolactam, and 3 parts by weight of 6-aminocaproic acid were mixed, vigorously mixed by physical means, and then ultrasonically dispersed at 80°C for 3 hours to form a premix. The premix was vacuum-dried for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com