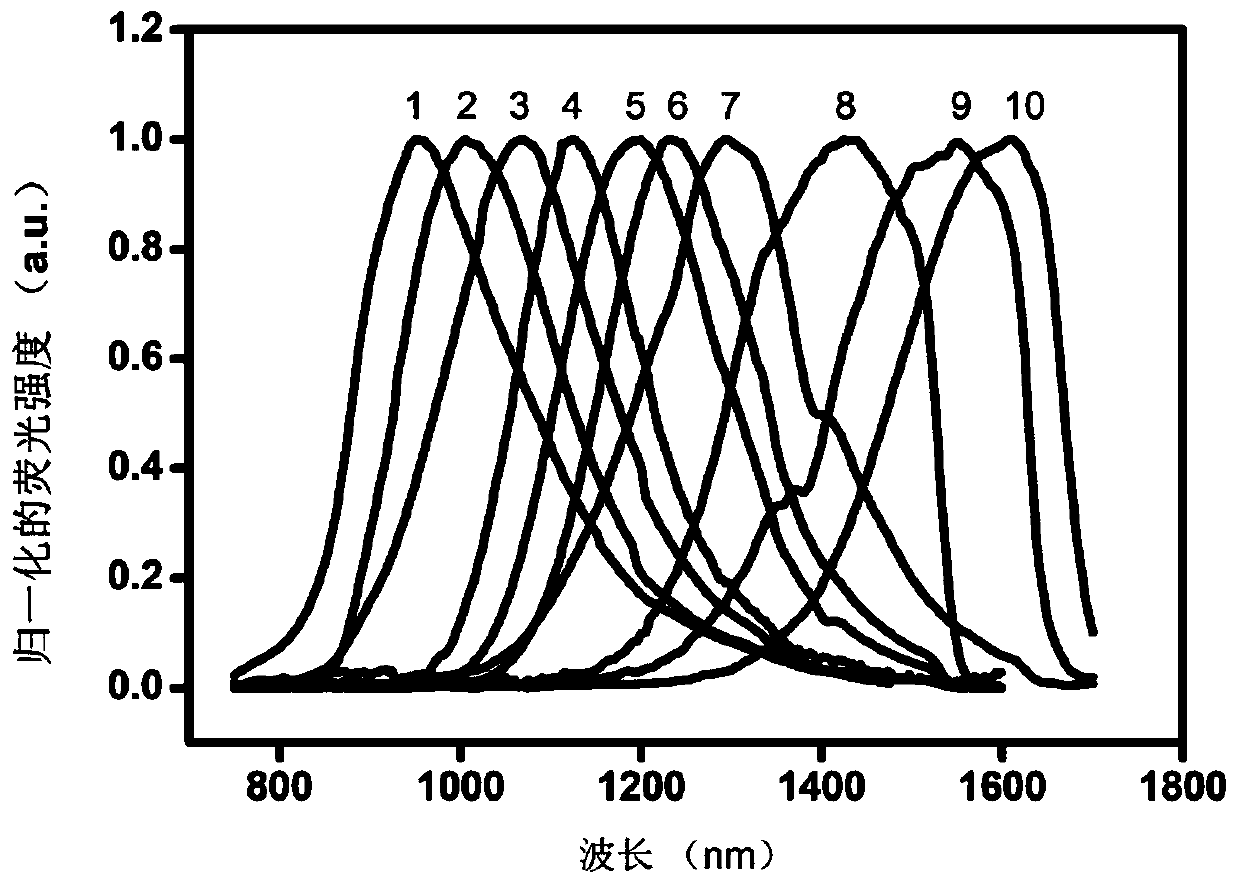

Method for preparing organic-phase silver selenide quantum dots with controllable sizes

A quantum dot and organic phase technology, which is applied in the field of preparation of size-controllable organic phase silver selenide quantum dots, can solve the problems of narrow control range of quantum dot size, uncontrollable fluorescence emission peak, complex preparation of selenium precursors, etc., to achieve Low price of raw materials, conducive to industrial production and promotion, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

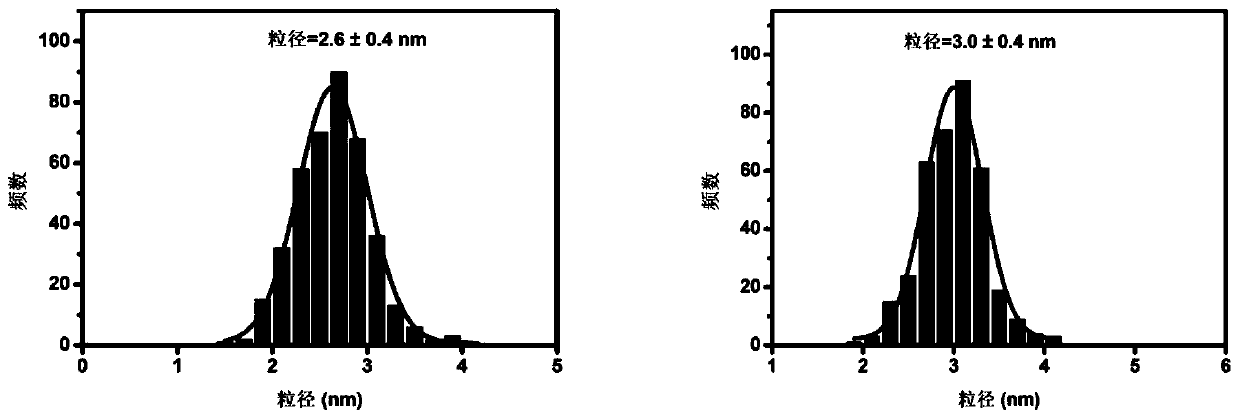

Embodiment 1

[0037] Add 1mmol of silver acetate, 10mmol of n-octyl mercaptan, and 10mL of 1-octadecene into a three-necked flask equipped with a thermometer and a condenser tube. Under stirring conditions, pass argon under the liquid surface and heat to 120°C; until completely dissolved After that, change to the liquid surface to ventilate and continue to heat up. At the same time, 0.1mmol selenium powder, 0.8mL oleylamine, and 1.1mL 1-octadecene were mixed and ultrasonicated to obtain a selenium precursor. When the temperature rose to 160°C, the above-mentioned selenium precursor was quickly injected into the three-neck flask with a syringe, the temperature was lowered to 120°C, and the temperature was kept for 10 minutes. Cool down to room temperature, add 10 mL of acetonitrile and 50 mL of acetone, centrifuge at 10,000 rpm for 5 min, discard the supernatant to obtain a precipitate, and then purify twice through tetrachlorethylene dispersion of acetonitrile plus acetone precipitation ste...

Embodiment 2

[0039] Add 0.9mmol of silver acetate, 10mmol of n-octyl mercaptan, and 10mL of 1-octadecene into a three-necked flask equipped with a thermometer and a condenser tube, and heat to 120°C with argon under the liquid surface under stirring conditions; After dissolving, change to the liquid surface to ventilate, and continue to heat up. At the same time, 0.1mmol selenium powder, 0.8mL oleylamine, and 1.1mL 1-octadecene were mixed and ultrasonicated to obtain a selenium precursor. When the temperature rose to 160°C, the above-mentioned selenium precursor was quickly injected into the three-neck flask with a syringe, the temperature was lowered to 120°C, and the temperature was kept for 10 minutes. Cool down to room temperature, add 10 mL of acetonitrile and 50 mL of acetone, centrifuge at 10,000 rpm for 5 min, discard the supernatant to obtain a precipitate, and then purify twice through tetrachlorethylene dispersion of acetonitrile plus acetone precipitation steps, disperse in tet...

Embodiment 3

[0041]Add 0.55mmol of silver acetate, 10mmol of n-octyl mercaptan, and 10mL of 1-octadecene into a three-necked flask equipped with a thermometer and a condenser tube. Under stirring conditions, pass argon under the liquid surface and heat to 120°C; After dissolving, change to the liquid surface to ventilate, and continue to heat up. At the same time, 0.1mmol selenium powder, 0.8mL oleylamine, and 1.1mL 1-octadecene were mixed and ultrasonicated to obtain a selenium precursor. When the temperature rose to 170°C, the above-mentioned selenium precursor was quickly injected into the three-necked flask with a syringe, the temperature was lowered to 120°C, and the temperature was kept for 10 minutes. Cool down to room temperature, add 10 mL of acetonitrile and 50 mL of acetone, centrifuge at 10,000 rpm for 5 min, discard the supernatant to obtain a precipitate, and then purify twice through tetrachlorethylene dispersion of acetonitrile plus acetone precipitation steps, disperse in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com