Preparation method for soft magnetic ferrite with high saturation magnetic induction strength and high magnetic permeability

A technology of magnetic induction intensity and soft ferrite, which is applied in the field of preparation of soft ferrite with high saturation magnetic induction intensity and high magnetic permeability, can solve the problems such as unsatisfactory magnetic permeability and saturation magnetic induction intensity, unable to guarantee mass production, etc., and achieve easy follow-up. The effect of sintering, easy molding, high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

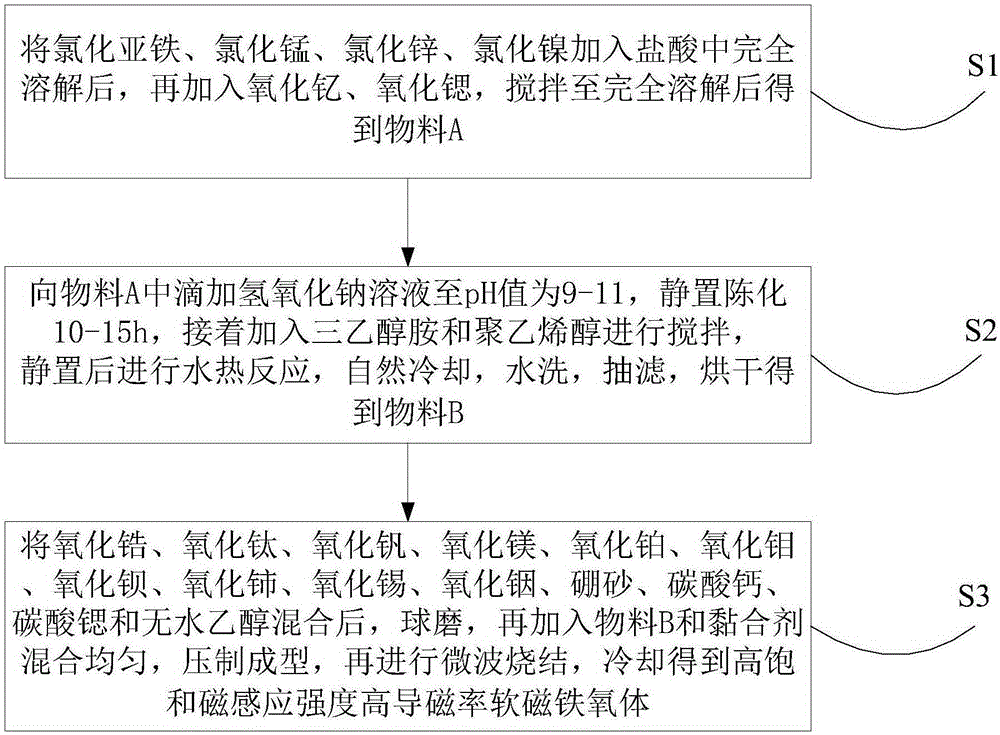

[0024] refer to figure 1 , the preparation method of a kind of high saturation magnetic induction intensity high magnetic permeability soft ferrite that the present invention proposes, comprises the following steps:

[0025] S1. Add ferrous chloride, manganese chloride, zinc chloride, and nickel chloride to hydrochloric acid to completely dissolve them, then add yttrium oxide and strontium oxide, and stir until completely dissolved to obtain material A;

[0026] S2. Add sodium hydroxide solution dropwise to the material A until the pH value is 9-11, let stand and age for 10-15h, then add triethanolamine and polyvinyl alcohol to stir, carry out hydrothermal reaction after standing, and cool naturally, Washing, suction filtration, and drying to obtain material B;

[0027] S3, after mixing zirconium oxide, titanium oxide, vanadium oxide, magnesium oxide, platinum oxide, molybdenum oxide, barium oxide, cerium oxide, tin oxide, indium oxide, borax, calcium carbonate, strontium car...

Embodiment 1

[0030] A kind of preparation method of high saturation magnetic induction intensity and high magnetic permeability soft ferrite proposed by the present invention comprises the following steps:

[0031] S1. Add 53 parts of ferrous chloride, 24 parts of manganese chloride, 18 parts of zinc chloride and 8 parts of nickel chloride into hydrochloric acid to completely dissolve in molar parts, then add 3.6 parts of yttrium oxide and 2.5 parts of strontium oxide, and stir After being completely dissolved, material A is obtained;

[0032] S2. Add dropwise sodium hydroxide solution to 100 parts of material A by weight until the pH value is 9, keep stirring during the dropwise addition of sodium hydroxide solution, let it stand for aging for 15 hours, then add 5 parts of triethanolamine and 10 parts Stir with 100% polyvinyl alcohol, carry out hydrothermal reaction after standing still, the temperature of hydrothermal reaction is 180 ℃, the time of hydrothermal reaction is 14h, natural c...

Embodiment 2

[0035] A kind of preparation method of high saturation magnetic induction intensity and high magnetic permeability soft ferrite proposed by the present invention comprises the following steps:

[0036] S1. Add 56 parts of ferrous chloride, 20 parts of manganese chloride, 22 parts of zinc chloride and 5 parts of nickel chloride into hydrochloric acid to completely dissolve in molar parts, then add 5.2 parts of yttrium oxide and 1.8 parts of strontium oxide, and stir After being completely dissolved, material A is obtained;

[0037]S2. Add dropwise sodium hydroxide solution to 100 parts of material A by weight until the pH value is 11, keep stirring during the dropwise addition of sodium hydroxide solution, let it stand for aging for 10 hours, then add 8 parts of triethanolamine and 4 parts Stir with 100% polyvinyl alcohol, carry out hydrothermal reaction after standing still, the temperature of hydrothermal reaction is 200 ℃, the time of hydrothermal reaction is 12h, natural co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com