High-efficiency preservative for cosmetics and preparation method of high-efficiency preservative

A technology for preservatives and cosmetics, applied in the field of high-efficiency preservatives for cosmetics and their preparation, can solve the problems of affecting the efficacy of cosmetics, occupying the proportion of cosmetics, and not having broad-spectrum, so as to expand the broad-spectrum sterilization and improve compatibility. , The effect of linear controllable shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

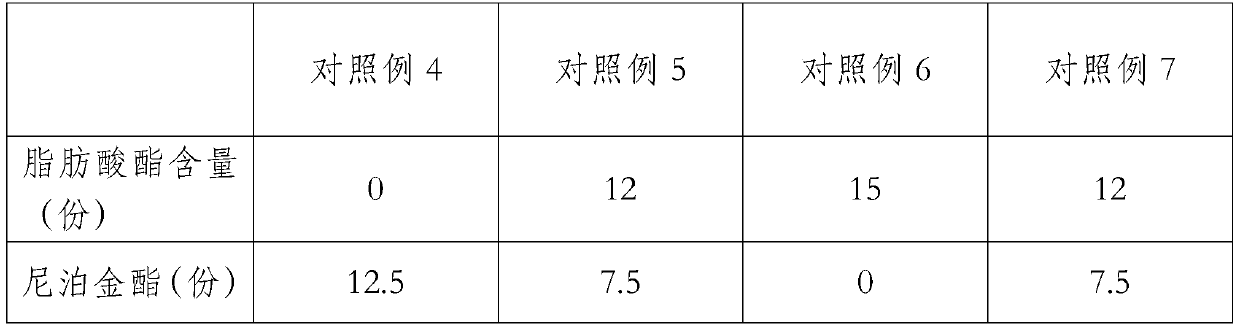

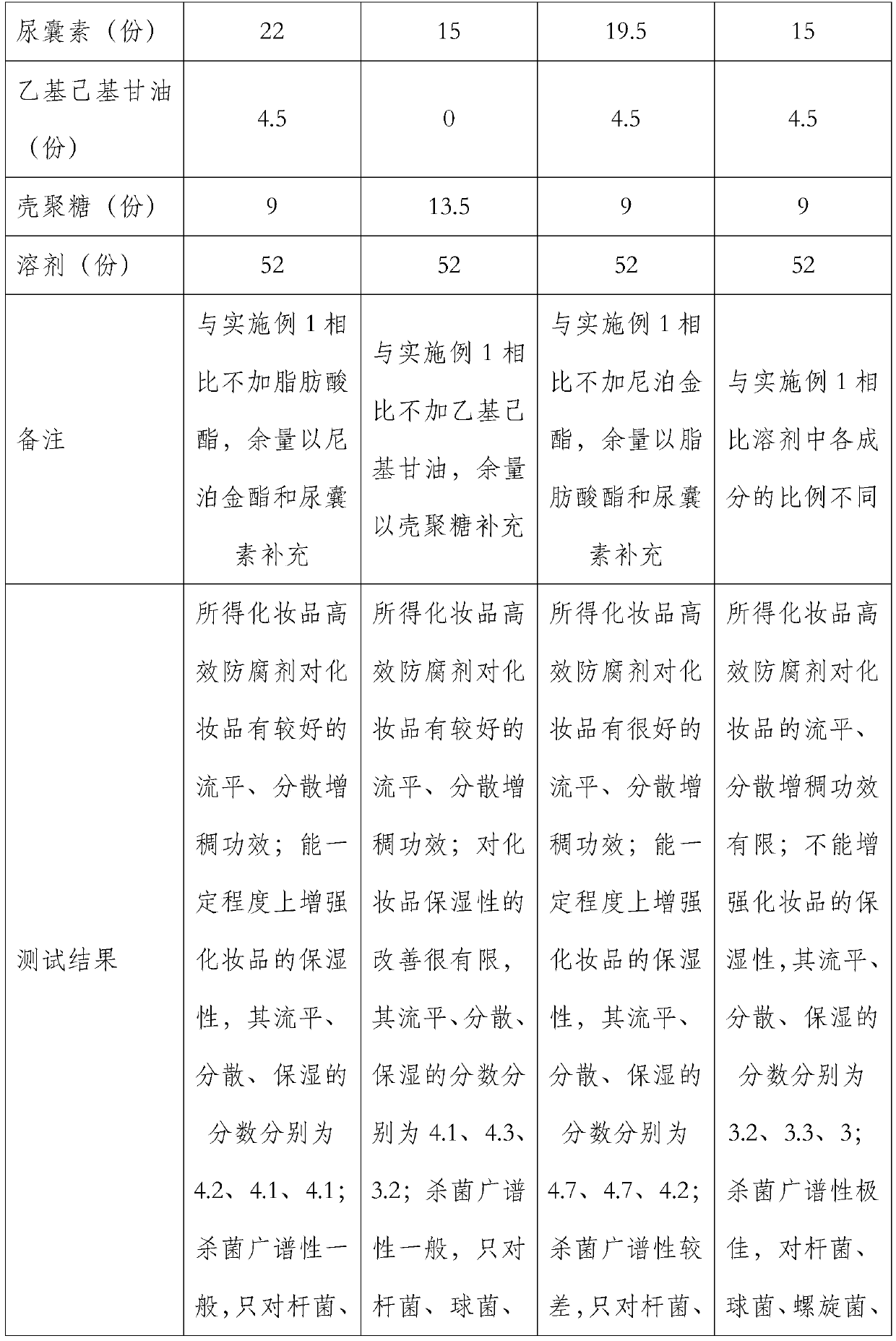

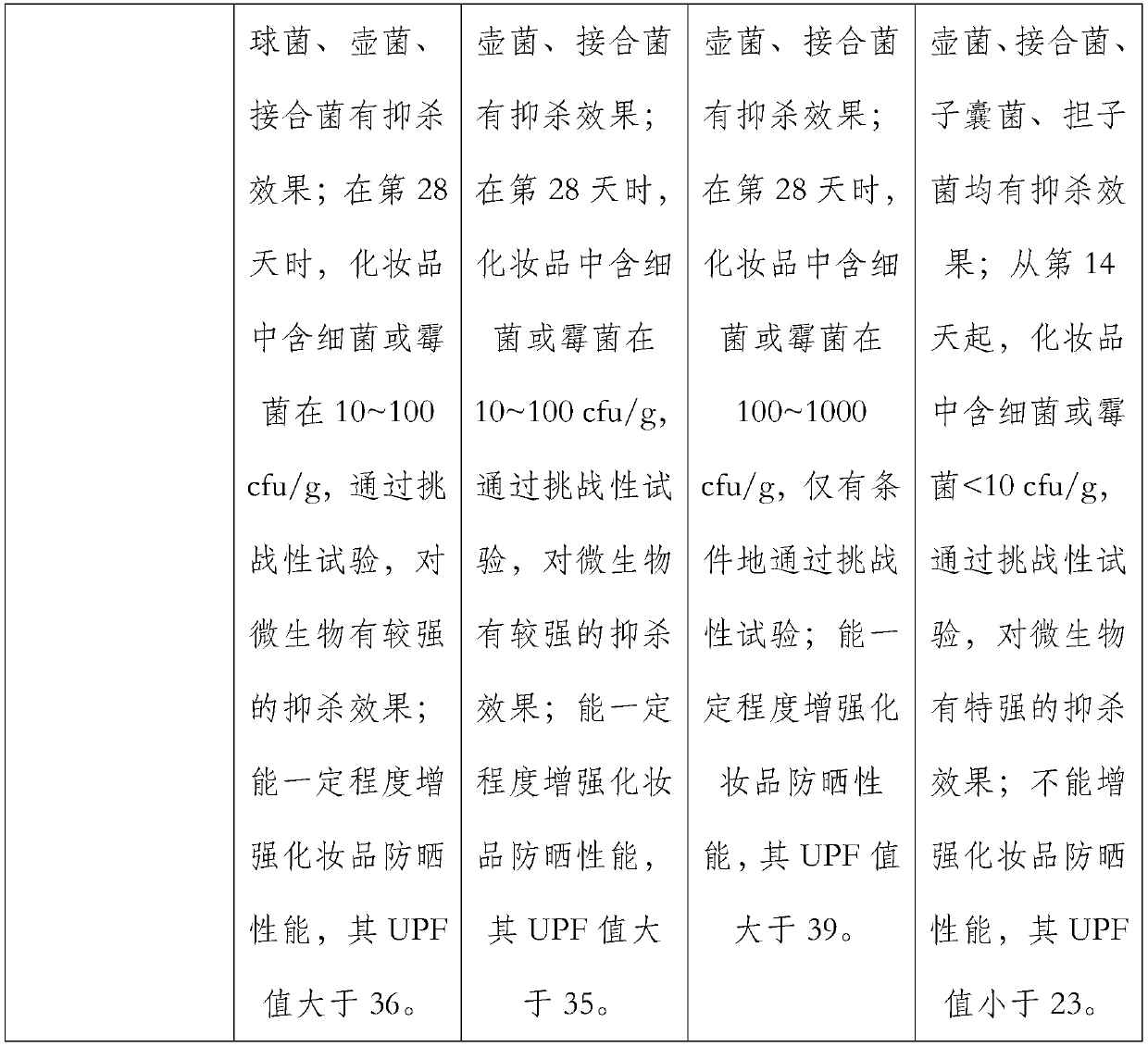

Examples

Embodiment 1

[0035] (1) At room temperature, in parts by mass, add 3 parts of sucrose fatty acid monoester, 4 parts of diglycerin fatty acid ester, 2 parts of ethylhexyl palmitate, 3 parts of ethylparaben, 2.5 parts of propylparaben, 2 parts of butylparaben, and 10.5 parts of allantoin were heated in a water bath to raise the temperature of the whole system to 37° C. and stirred and mixed uniformly at 90 rpm.

[0036] (2) Continue to slowly add 7.5 parts of water, 15 parts of ethanol, 17.5 parts of glycerol, 12 parts of 1,2-butanediol, 1 part of sucrose fatty acid monoester, and diglycerin fatty acid to the mixing system in (1). 1.33 parts of esters, 0.67 parts of ethylhexyl palmitate, 4.5 parts of allantoin, 4.5 parts of ethylhexylglycerin, 9 parts of chitosan, stirring at a speed of 120rpm while feeding, and the feeding is completed within 15min to obtain Highly effective preservative for cosmetics.

[0037] Test results: cosmetics with a preservative content of 0.01% have good leveling...

Embodiment 2

[0039] (1) Add 4.5 parts of sucrose fatty acid monoester, 1.5 parts of isopropyl myristate, 3 parts of ethylhexyl palmitate, 2.5 parts of methylparaben, and 3.5 parts of ethylparaben into the container at room temperature , 1.5 parts of butylparaben, 10.5 parts of allantoin, heated in a water bath to raise the temperature of the whole system to 37 ° C and stirred and mixed evenly at 90 rpm;

[0040](2) Continue to slowly add 7.5 parts of water, 15 parts of ethanol, 17.5 parts of glycerol, 12 parts of 1,2-butanediol, 1.5 parts of sucrose fatty acid monoester, and iso-myristic acid to the mixing system in (1). 0.5 parts of propyl ester, 1 part of ethylhexyl palmitate, 4.5 parts of allantoin, 4.5 parts of ethylhexylglycerin, 9 parts of chitosan, stir at a speed of 120rpm while feeding, and complete the feeding within 15min, that is High-efficiency preservative for cosmetics.

[0041] Test results: cosmetics with a preservative content of 0.01% have good leveling, dispersing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com