Gallium-contained polycaprolactone/bioglass porous bone repair 3D printing support and application thereof in infectious bone defect repair

A technology of bioglass and polycaprolactone, which is applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of soft tissue damage, easy adhesion, and high risk of bacterial exposure, so as to promote osteogenic differentiation and inhibit osteoclast differentiation , the effect of uniform distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

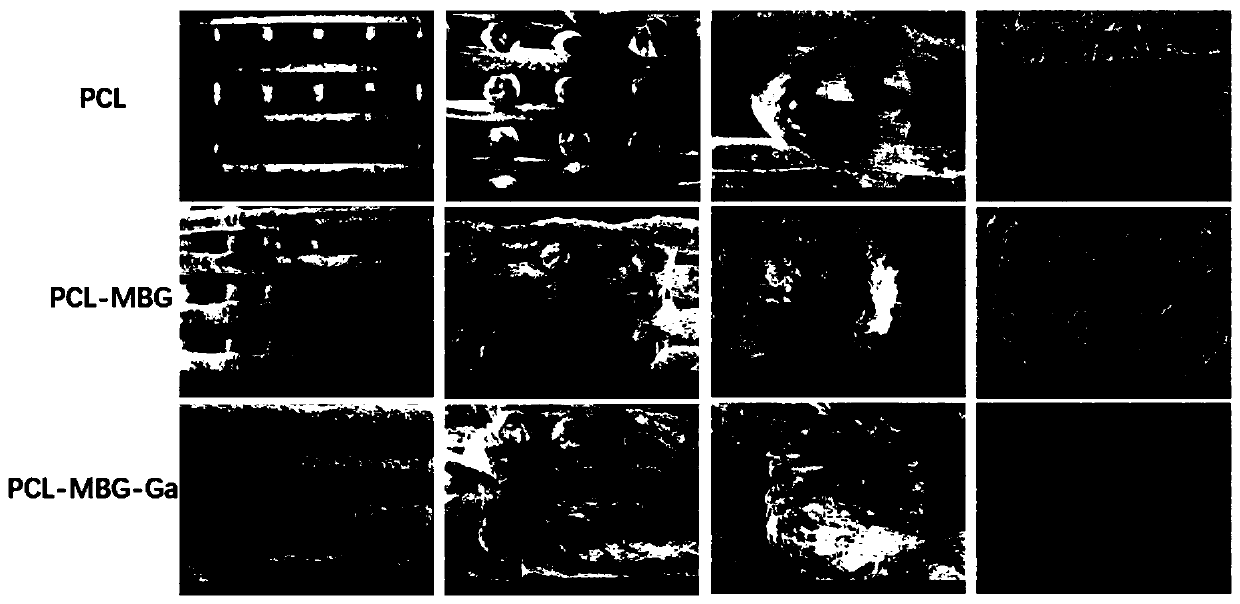

[0037] 3D printing and material science characterization of embodiment 1 bracket

[0038] 1.1 Fully stir and mix the prepared bioglass powder containing 8% gallium with PCL dissolved in dichloromethane respectively to make a paste suitable for printing and put it into the barrel, wherein the bioglass powder containing gallium and The mass ratio of PCL is 3:7. Set a circular model with a diameter of 10mm and a height of 2mm on the 3D bioprinting of ENVISION TEC, and set the height of each layer to 0.32mm. Set the printing speed to 3mm / s, the printing temperature to 25°C, and the extrusion pressure to 2bar. After the printed stent is dried, it is sprayed with gold, and the scanning electron microscope is taken and analyzed by EDS.

[0039] figure 1 It is the result figure of the scanning electron microscope in embodiment 1.1, figure 1 It was shown that the surface of the stent containing bioglass was rougher than that of the pure PCL stent.

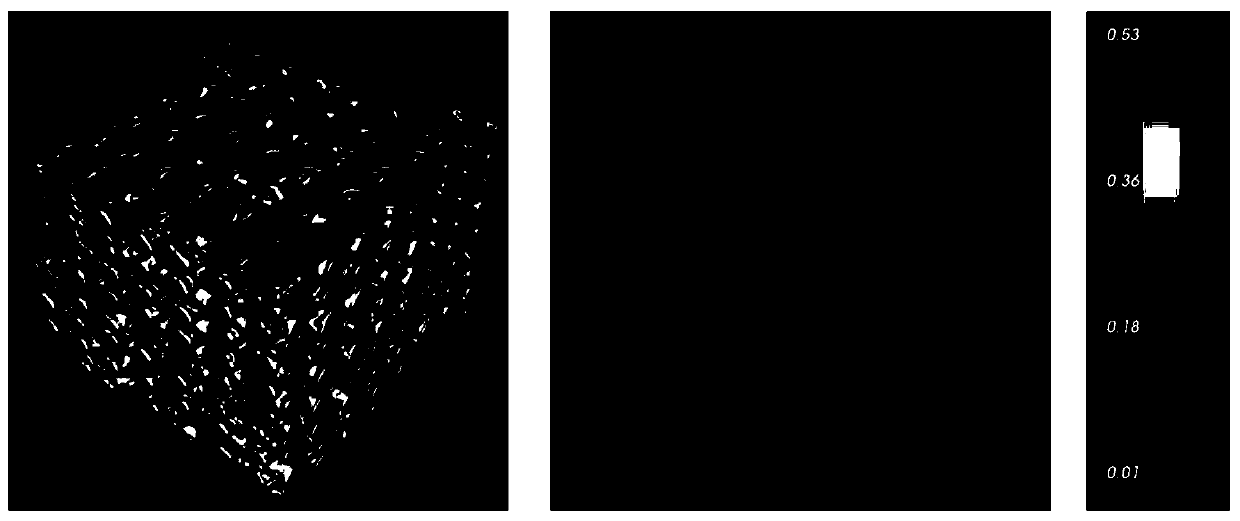

[0040] 1.2 Print a stent with a...

Embodiment 2

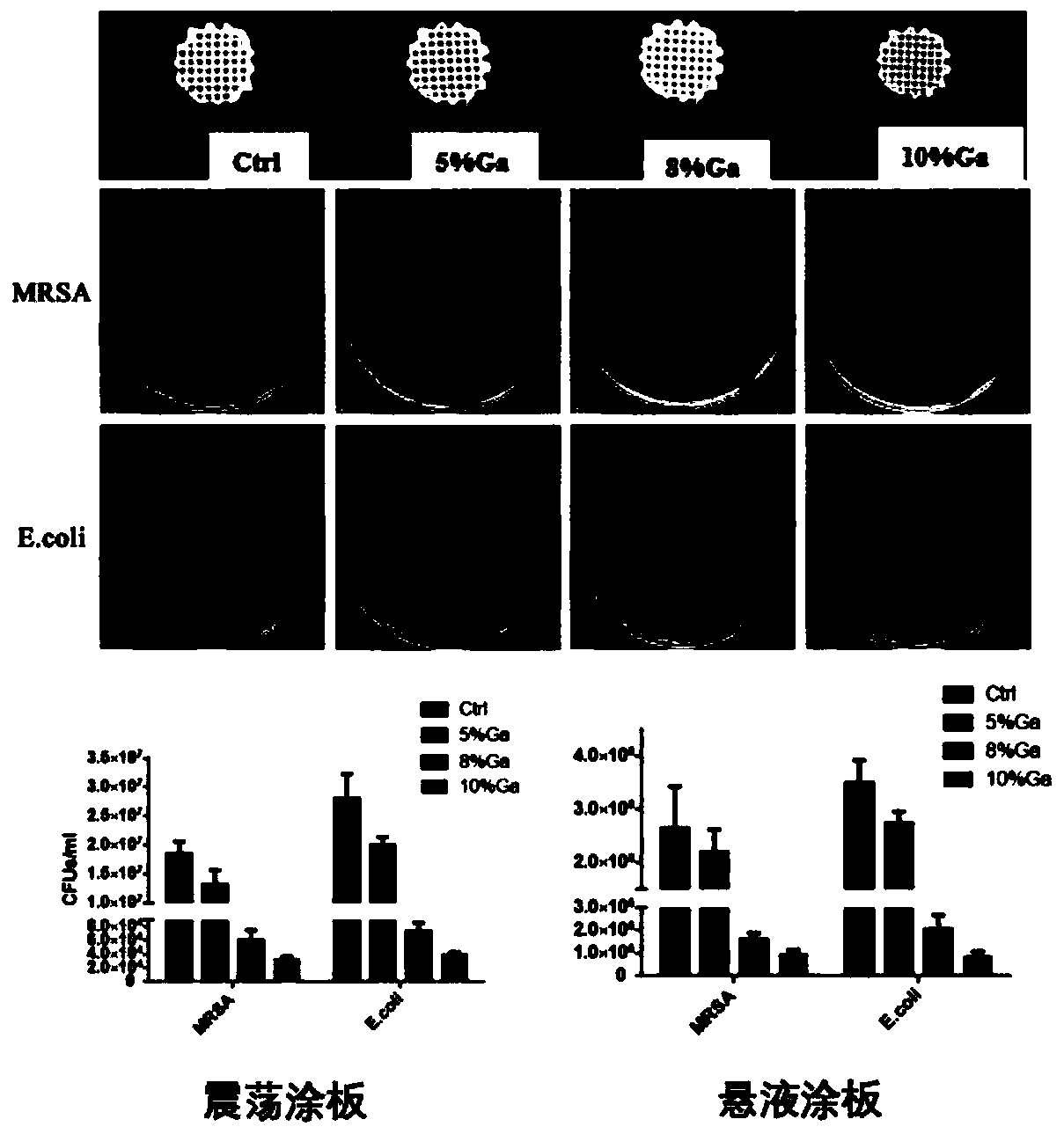

[0042] Example 2 Evaluation of the antibacterial effect of gallium-containing polycaprolactone / bioglass 3D printing scaffold on methicillin-resistant Staphylococcus aureus (MRSA) and Escherichia coli (E.coli)

[0043] 2.1 After ultrasonic vibration, the number of bacteria adhered to the surface of the scaffold was quantified by gradient dilution plate counting, which proved the ability of the scaffold to inhibit bacterial proliferation. Place the sterilized scaffold in a 24-well plate, add 1mL of 1*10^ 6 CFUs / mL of E.coli and MRSA bacteria solution, after incubating in a 37-degree incubator for 24 hours, take out the inner bracket of the orifice plate in the ultra-clean bench, gently rinse it in PBS three times, put it into a sterile centrifuge tube, Add 2 mL of LPBS to completely immerse the scaffold in the liquid, and ultrasonically shake for 15 minutes. The resulting bacterial suspension is plated and counted by gradient dilution. After incubation in the incubator for 24 ho...

Embodiment 3

[0047] Example 3 evaluates the promotion effect of gallium-containing polycaprolactone / bioglass 3D printing scaffold on the osteogenic differentiation of BMSCs and the inhibitory effect on the osteoclastic differentiation of BMM.

[0048] 3.1 The BMSCs of the primary isolation of 4-week-old male C57 mice were used as 1*10^ 5 The density of each well was planted in a 12-well plate. After the cells adhered to the wall overnight, an osteogenic induction medium and a transwell chamber with a scaffold in the upper chamber were added. The medium was changed every 3 days, and alkaline phosphatase (ALP ) staining to observe the promotion effect of 3D printed scaffolds on the osteogenic differentiation ability of BMSCs. Alizarin red staining was performed on day 21 to observe the effect of scaffolds on the late mineralization of BMSCs.

[0049] Figure 5 It is the experimental result of alkaline phosphatase in Example 3.1. It can be seen that the scaffold containing bioglass can prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com