Preparation method of modified ultrafiltration membrane by layer-by-layer self-assembly technology

A layer-by-layer self-assembly, ultrafiltration membrane technology, applied in the field of membrane separation, can solve the problems of poor hydrophilicity and antifouling properties of ultrafiltration membranes, complex processes, etc., and achieve the effect of strong practicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

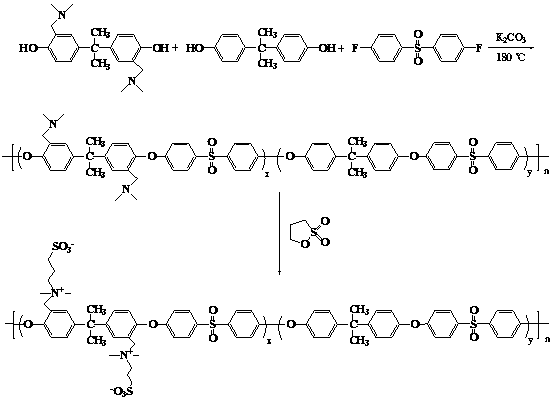

[0023] This embodiment provides a method for preparing a modified ultrafiltration membrane layer by layer self-assembly technology, such as figure 1 As shown, the method includes the following steps:

[0024] Step 1: Preparation of tertiary amino polysulfone polymer: (1) Under the protection of nitrogen, 3.08g bisphenol A, 0.52g 2,2-dimethylaminomethylene-4,4-bisphenol A, 3.71 g 4,4'-difluorodiphenylsulfone and 5g potassium carbonate were added to 100ml dimethyl sulfoxide solution for copolymerization, 50ml toluene was added as a water-carrying agent, and reacted at 180℃ for 12h; (2) After the reaction, the mixed system Pour into deionized water to precipitate; (3) Wash with distilled water, filter, and vacuum dry at 220°C for 12 h.

[0025] Step 2. Preparation of zwitterionic polysulfone polymer: (1) Dissolve 332 mg of methacryl ethyl sulfobetaine (SBMA) and 4.6 g of tertiary amino polysulfone polymer in a mixture of chloroform, 80 The reaction was heated and stirred at ℃ for 18h...

Embodiment 2

[0033] This embodiment provides a method for preparing a layer-by-layer self-assembly technology modified ultrafiltration membrane. The method includes the following steps:

[0034] Step 1: Preparation of tertiary amino polysulfone polymer: (1) Under the protection of nitrogen, 3.86g bisphenol A, 0.41g 2,2-dimethylaminomethylene-4,4-bisphenol A, 3.92g 4,4'-difluorodiphenylsulfone and 6g potassium carbonate were added to 150ml dimethyl sulfoxide solution for copolymerization, 80ml toluene was added as a water-carrying agent, and reacted at 200℃ for 18h; (2) After the completion of the mixed system Pour into deionized water to precipitate; (3) Wash with distilled water and dry in vacuum at 250°C for 12 hours.

[0035] Step 2. Preparation of zwitterionic polysulfone polymer: (1) Dissolve 364 mg of methacryl ethyl sulfobetaine (SBMA) and 5.2 g of tertiary amino polysulfone polymer in a chloroform mixture, 60 The reaction was heated and stirred at ℃ for 24h; (2) After the reaction was ...

Embodiment 3

[0042] This embodiment provides a method for preparing a layer-by-layer self-assembly technology modified ultrafiltration membrane. The method includes the following steps:

[0043] Step 1: Preparation of tertiary amino polysulfone polymer: (1) Under the protection of nitrogen, mix 4.02g bisphenol A, 0.66g 2,2-dimethylaminomethylene-4,4-bisphenol A, 4.3g 4,4'-difluorodiphenyl sulfone and 8g potassium carbonate were added to 180ml dimethyl sulfoxide solution for copolymerization, 90ml toluene was added as a water-carrying agent, and reacted at 220℃ for 22h; (2) After the completion of the mixed system Pour into deionized water to precipitate; (3) Wash with distilled water and dry in vacuum at 250°C for 12 hours.

[0044] Step 2. Preparation of zwitterionic polysulfone polymer: (dissolve) 283 mg of methacryl ethyl sulfobetaine (SBMA) and 5.5 g of tertiary amino polysulfone polymer in a mixture of chloroform at 80°C Under heating and stirring reaction for 24h; (2) After the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com