0D/2D iron phosphide/cadmium sulfide composite photocatalyst, and preparation method and application thereof

A technology of cadmium sulfide and iron phosphide, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problems of poor photocatalytic hydrogen production performance of cadmium sulfide, etc. High ratio of exposed active sites, improved catalytic activity, and superior material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

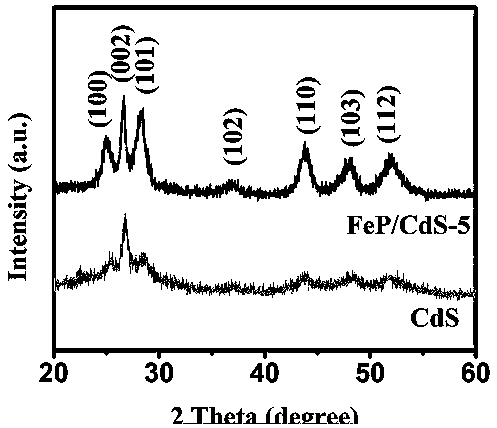

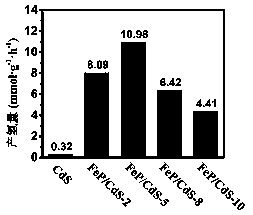

[0029] 200 mg of 2D cadmium sulfide nanosheets prepared by the hydrothermal method were dissolved in 200 mL of deionized water to make a solution with a concentration of 1 g / L, which was ultrasonicated in an ultrasonic machine for 2 h, keeping the water temperature at about 15 °C. Then add 4.6 mL of Fe(NO 3 ) 3 9H 2 O solution. React for 3 h under dark conditions. After the reaction, the solution was allowed to stand for 30 minutes, then the supernatant was poured out, and the centrifuge tubes were washed alternately with deionized water and alcohol. The speed of the centrifuge was set at 8000r / min. Finally, the washed precipitate in the centrifuge tube was dried in an oven at 60° C. for 15 h. NaH 2 PO 2 According to the mass ratio of the obtained dry matter to 10:1, put them into the upper tuyere and the lower tuyere of the porcelain boat respectively, and place them in a tube furnace for calcination. The calcination time is 2 h, and the heating rate is 2 h. o C / min, ...

Embodiment 2

[0031] 200 mg of 2D cadmium sulfide nanosheets prepared by the hydrothermal method were dissolved in 200 mL of deionized water to make a solution with a concentration of 1 g / L, which was ultrasonicated in an ultrasonic machine for 2 h, keeping the water temperature at about 15 °C. Then add 11.6 mL of Fe(NO 3 ) 3 9H 2 O solution. React for 3 h under dark conditions. After the reaction, the solution was allowed to stand for 30 minutes, then the supernatant was poured out, and the centrifuge tubes were washed alternately with deionized water and alcohol. The speed of the centrifuge was set at 8000r / min. Finally, the washed precipitate in the centrifuge tube was dried in an oven at 60° C. for 15 h. NaH 2 PO 2 According to the mass ratio of the obtained dry matter to 10:1, put them into the upper tuyere and the lower tuyere of the porcelain boat respectively, and place them in a tube furnace for calcination. The calcination time is 2 h, and the heating rate is 2 h. o C / min,...

Embodiment 3

[0035]200 mg of 2D cadmium sulfide nanosheets prepared by the hydrothermal method were dissolved in 200 mL of deionized water to make a solution with a concentration of 1 g / L, which was ultrasonicated in an ultrasonic machine for 2 h, keeping the water temperature at about 15 °C. Then add 18.6 mL of Fe(NO 3 ) 3 9H 2 O solution. React for 3 h under dark conditions. After the reaction, the solution was allowed to stand for 30 min, and the supernatant was poured out, and washed alternately with deionized water and alcohol in a centrifuge tube. The speed of the centrifuge was set at 8000 r / min. Finally, the washed precipitate in the centrifuge tube was dried in an oven at 60° C. for 15 h. NaH 2 PO 2 According to the mass ratio of the obtained dry matter to 10:1, put them into the upper tuyere and the lower tuyere of the porcelain boat respectively, and place them in a tube furnace for calcination. The calcination time is 2 h, and the heating rate is 2 h. o C / min, the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com