Nitrogen-doped nickel phosphide nano-flower, preparation method and applications thereof

A technology of nickel phosphide and nanoflowers, applied in chemical instruments and methods, phosphides, nanotechnology, etc., to achieve the effect of simple and easy process, high stability and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

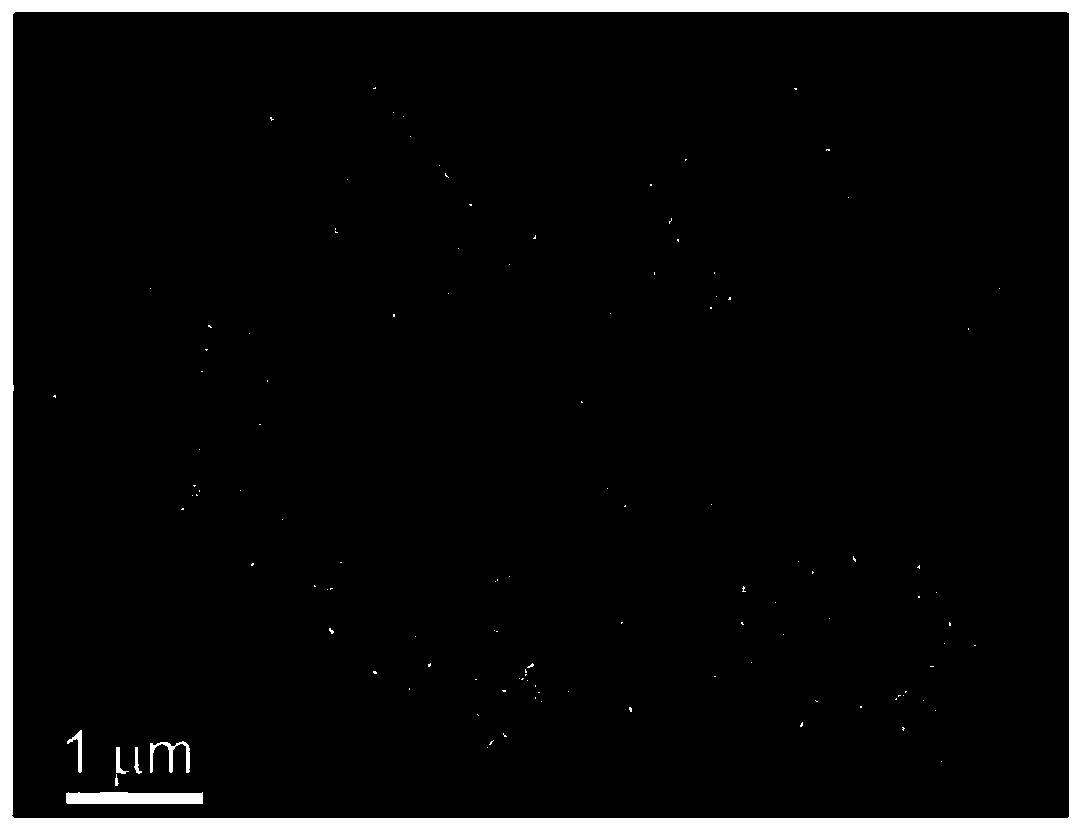

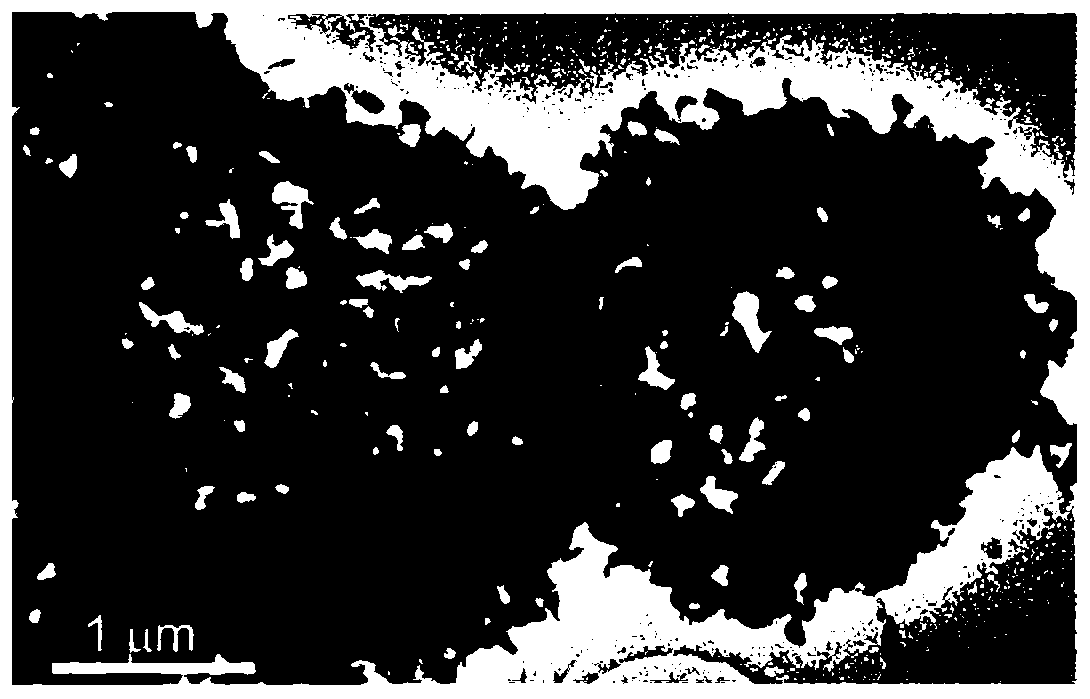

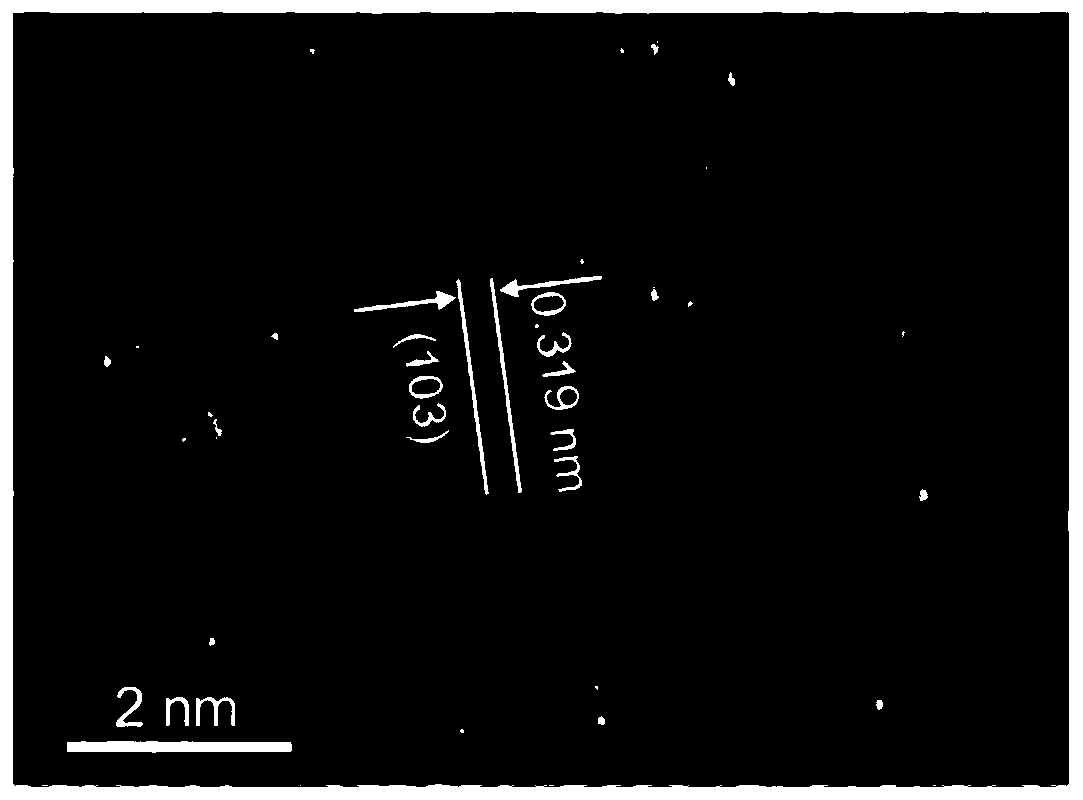

Image

Examples

Embodiment 1

[0037] A preparation method of nitrogen-doped nickel phosphide nanoflowers, comprising the following steps:

[0038] 1)Ni(OH) 2 Preparation of nanoflowers: Dissolve nickel nitrate in absolute ethanol, fully dissolve, add a mixed solution of oleylamine and ethanol during stirring, stir for 30 minutes, transfer to a 50mL reaction kettle, and conduct a hydrothermal reaction in an oven at 180°C for 15 hours. Centrifuged and dried to obtain Ni(OH) 2 nanoflowers;

[0039] 2) Preparation of NiO nanoflowers: Ni(OH) 2 The nanoflowers were placed in a porcelain boat, and in an air atmosphere, the temperature was programmed to rise to 300°C at 2°C / min for heat treatment, and kept at this temperature for 60 minutes, and then cooled to obtain NiO nanoflowers.

[0040] 3) Preparation of nitrogen-doped nickel phosphide nanoflowers: According to the mass ratio of NiO nanoflowers to sodium hypophosphite of 1:30 and the mass ratio of ammonium bicarbonate to 1:2, sodium hypophosphite, bicarbo...

Embodiment 2

[0042] A preparation method of nitrogen-doped nickel phosphide nanoflowers, comprising the following steps:

[0043] 1)Ni(OH) 2 Preparation of nanoflowers: Dissolve nickel nitrate in absolute ethanol, fully dissolve, add a mixed solution of oleylamine and ethanol during stirring, stir for 30 minutes, transfer to a 50mL reaction kettle, and conduct a hydrothermal reaction in an oven at 180°C for 15 hours. Centrifuged and dried to obtain Ni(OH) 2 nanoflowers;

[0044] 2) Preparation of NiO nanoflowers: Ni(OH) 2 The nanoflowers were placed in a porcelain boat, and in an air atmosphere, the temperature was programmed to rise to 300°C at 2°C / min for heat treatment, and kept at this temperature for 60 minutes, and then cooled to obtain NiO nanoflowers.

[0045] 3) Preparation of nitrogen-doped nickel phosphide nanoflowers: According to the mass ratio of NiO nanoflowers to sodium hypophosphite of 1:30 and the mass ratio of ammonium bicarbonate to 1:1, sodium hypophosphite, bicarbo...

Embodiment 3

[0047] A preparation method of nitrogen-doped nickel phosphide nanoflowers, comprising the following steps:

[0048] 1)Ni(OH) 2 Preparation of nanoflowers: Dissolve nickel nitrate in absolute ethanol, fully dissolve, add oleylamine and ethanol mixed solution during stirring, stir for 30min, transfer to a 50mL reaction kettle, and conduct a hydrothermal reaction in an oven at 180°C for 15h. Centrifuged and dried to obtain Ni(OH) 2 nanoflowers;

[0049] 2) Preparation of NiO nanoflowers: Ni(OH) 2The nanoflowers were placed in a porcelain boat, and in an air atmosphere, the temperature was programmed to rise to 300°C at 2°C / min for heat treatment, and kept at this temperature for 60 minutes, and then cooled to obtain NiO nanoflowers.

[0050] 3) Preparation of nitrogen-doped nickel phosphide nanoflowers: According to the mass ratio of NiO nanoflowers to sodium hypophosphite of 1:30 and the mass ratio of ammonium bicarbonate to 1:5, sodium hypophosphite, bicarbonate Ammonium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com