Water-based epoxy curing agent based on castor oil triglycidyl ether and preparation method of curing agent

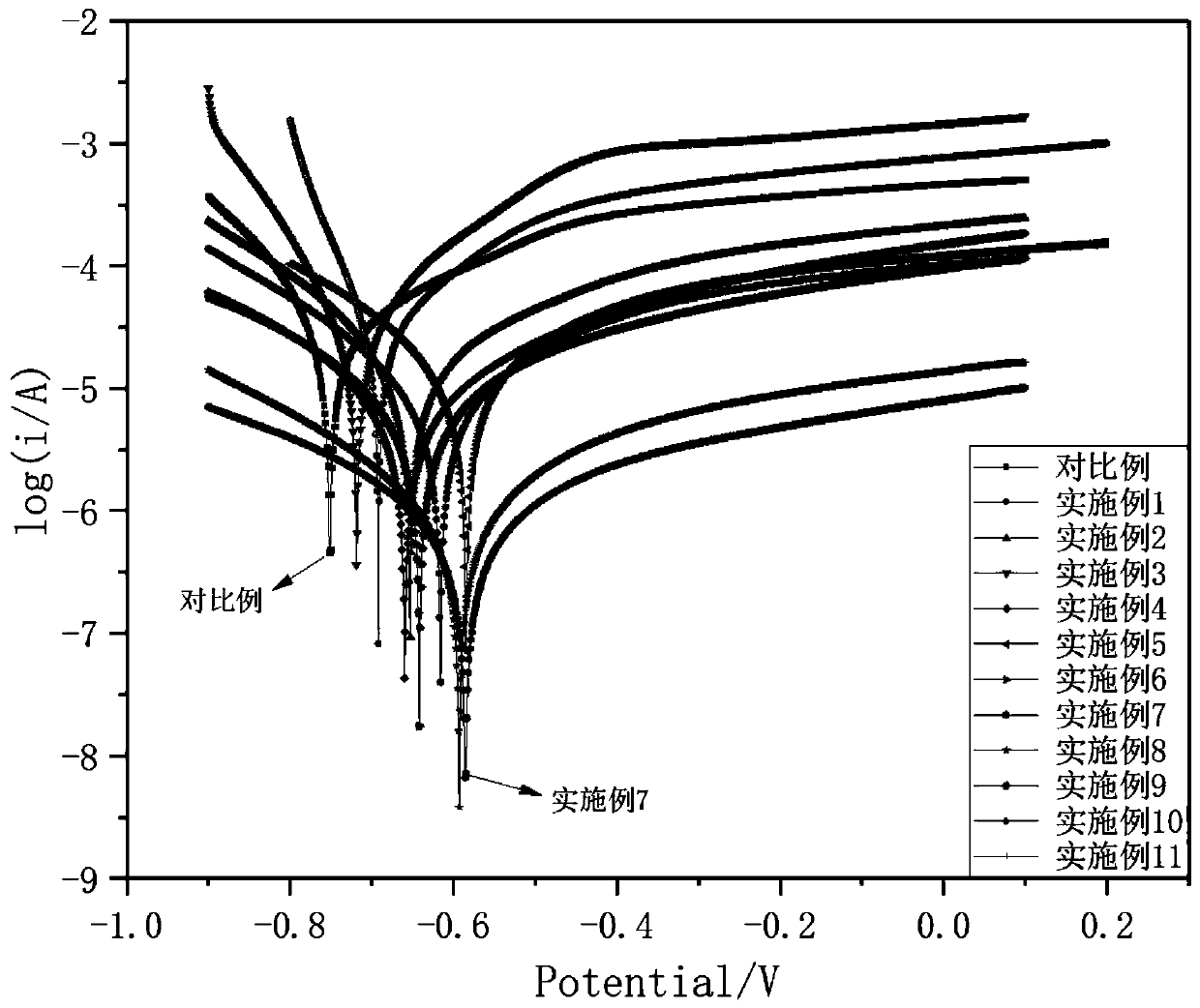

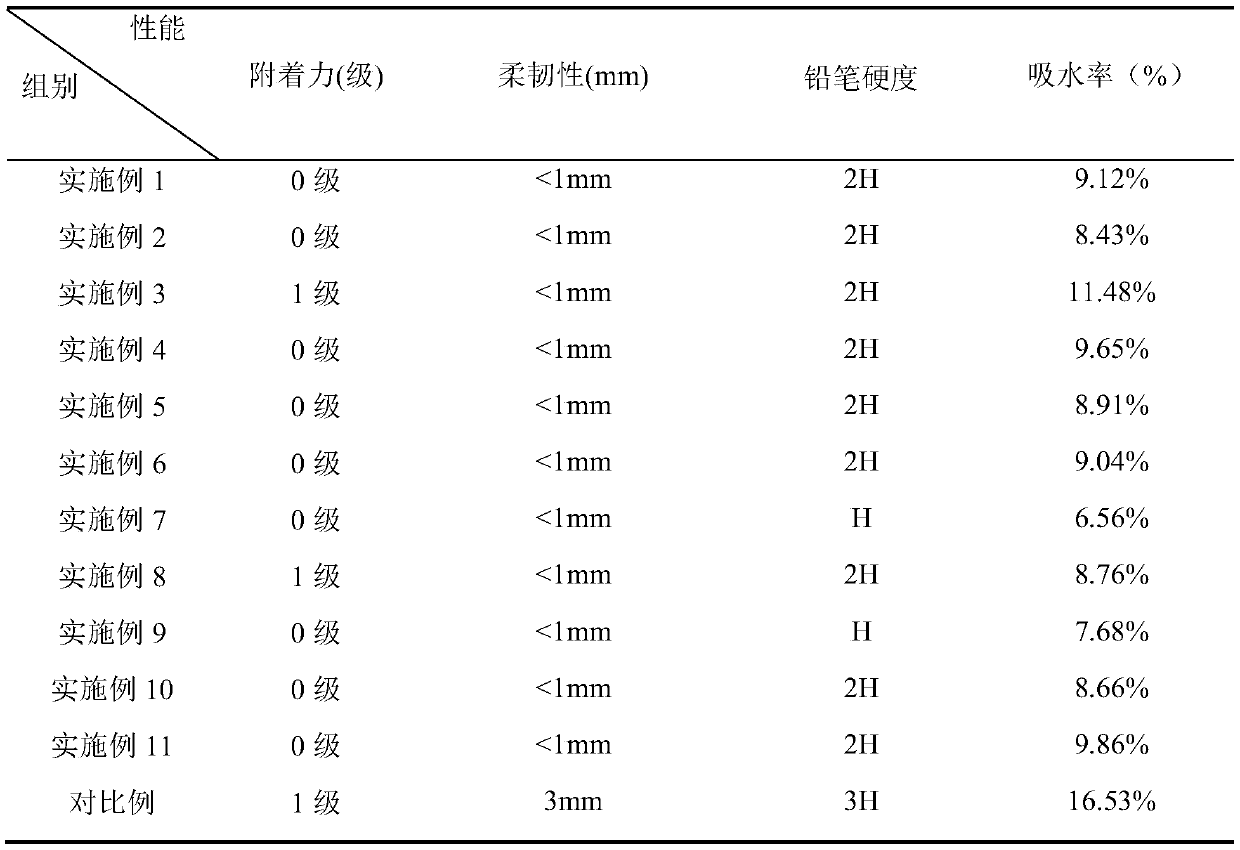

A technology of triglycidyl ether and diglycidyl ether, applied in the field of water-based epoxy curing agent and its preparation, can solve the problems of difficult control of TMPEG dosage, poor water resistance, slow surface drying speed, etc., and achieves good formula adjustability and adaptability, improve anti-corrosion performance, increase the effect of cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 13.16g (0.09mol) triethylenetetramine to a three-necked flask equipped with a stirrer and a condenser, heat to 65°C, then slowly add 14.11g (0.036mol) bisphenol A epoxy resin E51 Mix with 4.95g (0.009mol) of polyethylene glycol diglycidyl ether, and continue to react at 65°C for 3h to obtain -NH at both ends. 2 Epoxy-polyamine adduct 0.045mol.

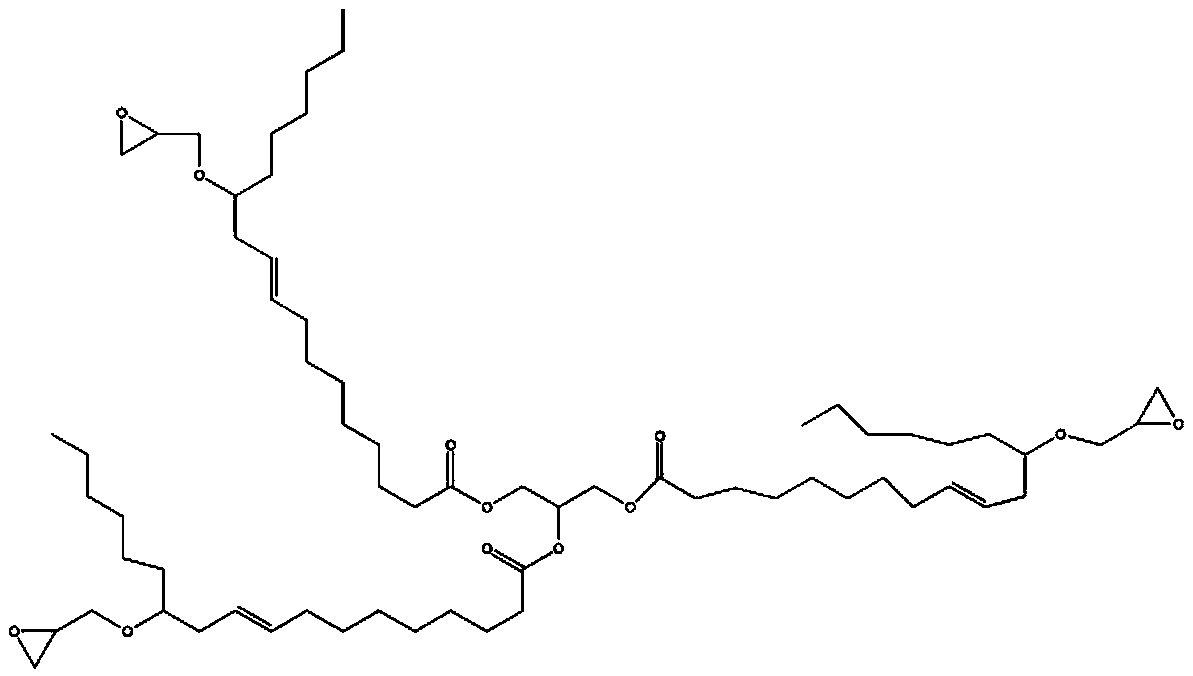

[0036] (2) Slowly add 16.52g (0.015mol) of castor oil triglycidyl ether into the epoxy-polyamine adduct obtained in step (1), and continue to react at 65°C for 3h to obtain a three-branch terminal -NH 2 Based prepolymer 0.015mol.

[0037] (3) Add 5.85 g (0.045 mol) of n-butyl glycidyl ether to the prepolymer obtained in step (2), and continue to react at 65° C. for 3 h to obtain a product whose terminal primary amine hydrogen has been blocked.

[0038] (4) Add deionized water to the product obtained in step (3), stir at 65° C. for 1 h, and adjust to obtain a three-branched water-based epoxy curing agent with a solid co...

Embodiment 2

[0040] Compared with Example 1, the preparation of a water-based epoxy curing agent based on castor oil triglycidyl ether of the present example is different in that the added triethylenetetramine is 15.13g (0.1mol), and the rest is completely same.

Embodiment 3

[0042]Compared with Example 1, the preparation of a water-based epoxy curing agent based on castor oil triglycidyl ether of the present example, the difference is that the added bisphenol A epoxy resin E51 is 10.58g (0.027mol) , polyethylene glycol diglycidyl ether is 9.9g (0.018mol), and the rest are identical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com