Preparation method of self-antibacterial castor oil based aqueous polyurethane emulsion

A water-based polyurethane and castor oil-based technology, applied in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of less application research and low toxicity, and achieve simplification Synthesis process, long-lasting antibacterial performance, and effect of maintaining antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

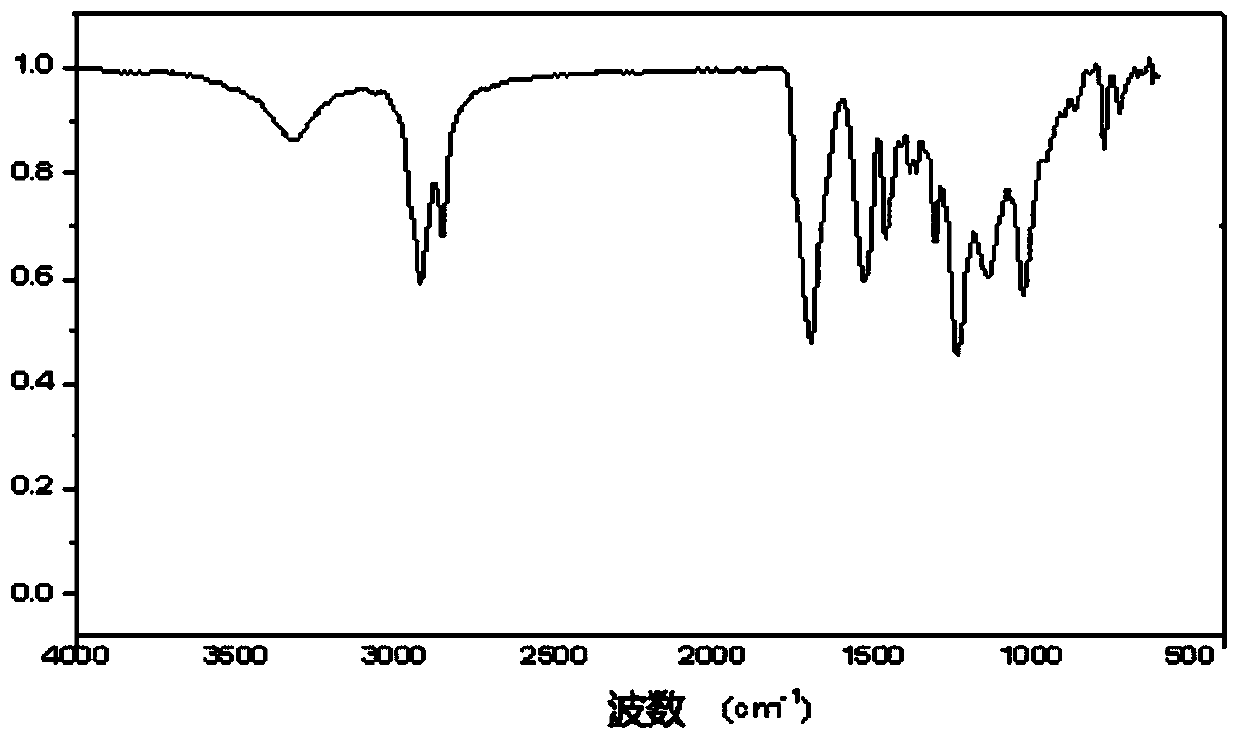

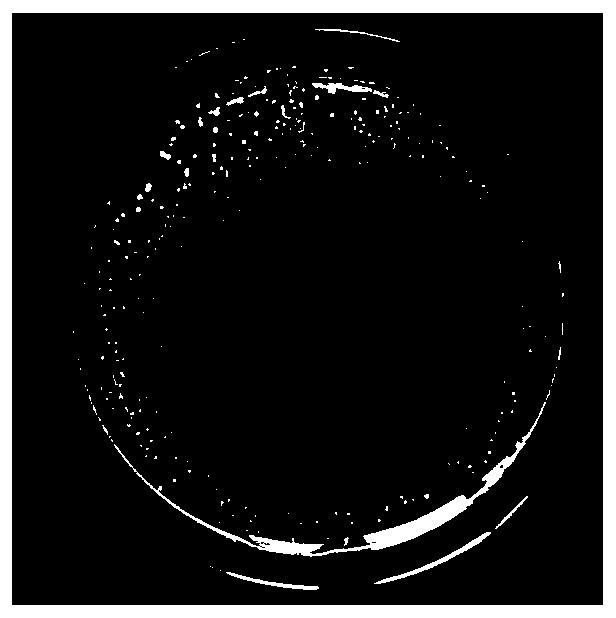

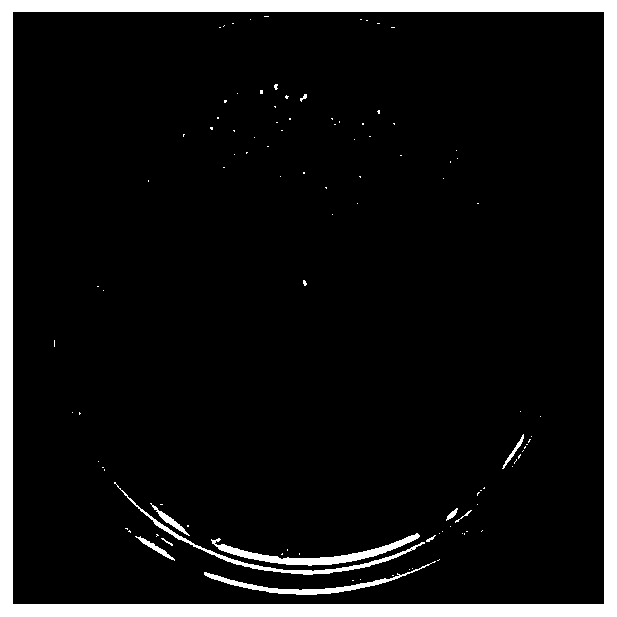

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of self-antibacterial castor oil-based aqueous polyurethane emulsion

[0032] 1. Add 18.66g of castor oil and 19.98g of IPD I (isophorone diisocyanate) into a three-necked flask, heat up to 45°C and add 2 drops of stannous octoate catalyst, and the system is in a nitrogen atmosphere Reaction at 75°C for 3h;

[0033] 2. Lower the temperature of the reaction system in step 1 to below 40°C, slowly add 1.35g of 1,4-butanediol, and then add 3mL of butanone to adjust the viscosity, and react the system at 65°C for 2 hours under a nitrogen atmosphere;

[0034] 3. Cool down the reaction system in step 2 to below 40°C, slowly add 3.57g (one drop of 2s) of N-methyldiethanolamine with a constant pressure funnel, then add 2mL of butanone to adjust the viscosity, and react the system at 60°C for 2h under nitrogen atmosphere;

[0035] 4. Cool down the reaction system in step 3 to below 35°C, add 0.17g sorbic acid and 1.5g acetic acid mixed solution dissolve...

Embodiment 2

[0039] Embodiment 2: Preparation of self-antibacterial castor oil-based aqueous polyurethane emulsion

[0040] 1. Add 18.66g of castor oil and 19.98g of I PDI (isophorone diisocyanate) into a three-necked flask, heat up to 45°C and add 2 drops of stannous octoate catalyst, and the system is under nitrogen atmosphere Reaction at 75°C for 3h;

[0041] 2. Cool down the reaction system in step 1 to below 40°C, slowly add 0.9g of 1,4-butanediol, then add 3mL of butanone to adjust the viscosity, and react the system at 65°C for 2h under nitrogen atmosphere;

[0042] 3. Cool down the reaction system in step 2 to below 35°C, slowly add 4.16g (one drop of 2s) N-methyldiethanolamine with a constant pressure funnel, then add 2mL butanone to adjust the viscosity, and react the system at 60°C for 2h under nitrogen atmosphere;

[0043] 4. Cool down the reaction system in step 3 to below 35°C, add a mixed solution of 0.26g sorbic acid and 1.9g acetic acid dissolved in butanone, after formin...

Embodiment 3

[0047] Embodiment 3: Preparation of self-antibacterial castor oil-based aqueous polyurethane emulsion

[0048] 1. Add 18.66g of castor oil and 19.98g of I PDI (isophorone diisocyanate) into a three-necked flask, heat up to 45°C and add 2 drops of stannous octoate catalyst, and the system is under nitrogen atmosphere Reaction at 75°C for 3h;

[0049] 2. Cool down the reaction system in step 1 to below 40°C, slowly add 1.8g of 1,4-butanediol, then add 3mL of butanone to adjust the viscosity, and react the system at 65°C for 2h under nitrogen atmosphere;

[0050] 3. Lower the temperature of the reaction system in step 2 to below 40°C, slowly add 3.1g (one drop of 2s) N-methyldiethanolamine with a constant pressure funnel, then add 2mL butanone to adjust the viscosity, and react the system at 60°C for 2h under a nitrogen atmosphere;

[0051] 4. Cool down the reaction system in step 3 to below 35°C, add a mixed solution of 0.35g sorbic acid and 1.3g acetic acid dissolved in methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com