One-dimensional cadmium sulfide/two-dimensional titanium carbide composite photocatalyst and preparation method and application thereof

A two-dimensional titanium carbide and cadmium sulfide technology, applied in the field of photocatalytic materials, can solve problems such as photocatalytic activity limitations, achieve good cycle performance, be conducive to sustainable development, and promote the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

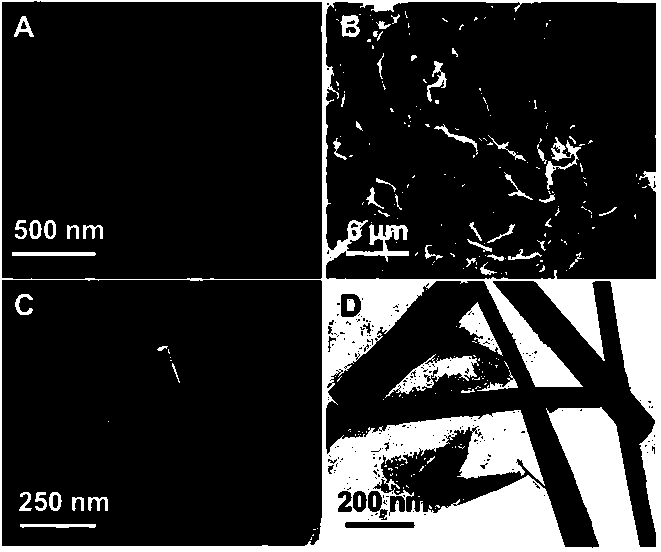

[0031] Example 1 Preparation of one-dimensional cadmium sulfide nanowire photocatalyst

[0032] Add 0.3 g / mL sodium diethyldithiocarbamate aqueous solution dropwise in 16.7 g / mL cadmium chloride solution by volume ratio 1:1 to obtain cadmium diethyldithiocarbamate; Cadmium thiocarbamate was added to ethylenediamine to form a solution with a concentration of 0.03 g / mL, then added to a polytetrafluoroethylene lining and sealed in a stainless steel autoclave, and the autoclave was placed in a 180°C Keep in the oven for 24 h, after cooling to room temperature, collect the bright yellow precipitate in the lining, wash with absolute ethanol and deionized water for 4 times (to the ion concentration in the washing solution <10 ppm), and store at 60 °C Dry in oven for 12h to obtain one-dimensional cadmium sulfide nanowires;

Embodiment 2

[0033] Example 2 Preparation of two-dimensional titanium carbide nanosheet photocatalyst

[0034] Add 1 g of titanium aluminum carbide powder into a plastic bottle containing 1 g of lithium fluoride, 3 mL of water, and 7 mL of hydrochloric acid in 5-6 times, and then stir for 24 h in an oil bath at 35 °C. The obtained product was washed several times until the pH value of the washing solution was close to neutral (6~7). The washed product was dispersed in 200 mL of water, ultrasonically dispersed for 60 min, and then centrifuged at 3500 rpm for 60 min to collect dark green A certain amount of deionized water was added to prepare a 1 g / L aqueous solution of two-dimensional titanium carbide nanosheets.

Embodiment 3

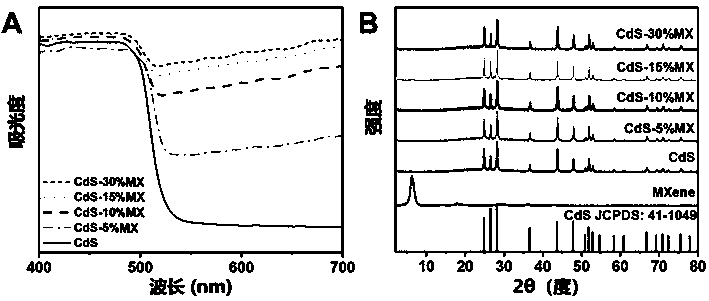

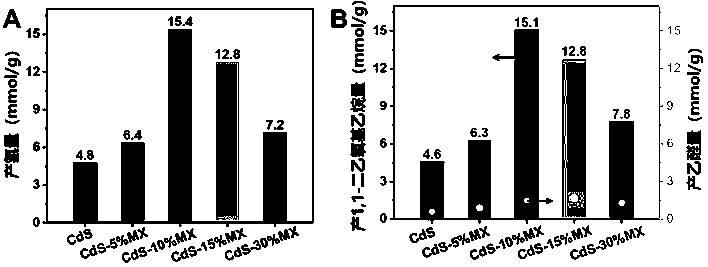

[0035] Example 3 Preparation of one-dimensional cadmium sulfide / two-dimensional titanium carbide (CdS-MX) composite photocatalyst

[0036]The one-dimensional cadmium sulfide (CdS) nanowires prepared in Example 1 were ultrasonically dispersed in deionized water, and then added dropwise to the aqueous solution of two-dimensional titanium carbide (MXene) nanosheets prepared in Example 2 (the mass ratio of MXene to CdS was 5% ), and stirred for 30-60 min, after suction filtration, deionized water washing and vacuum drying, the CdS-5%MX composite photocatalyst was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com