Linear salt-resistant polymer for oil displacement and preparation method thereof

A polymer, linear technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems affecting the quality and efficiency of polymer development, difficult water solubility and salt resistance, and reduced water solubility of polymers. , to achieve the effect of simple and feasible preparation method, improved salt resistance, and improved salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

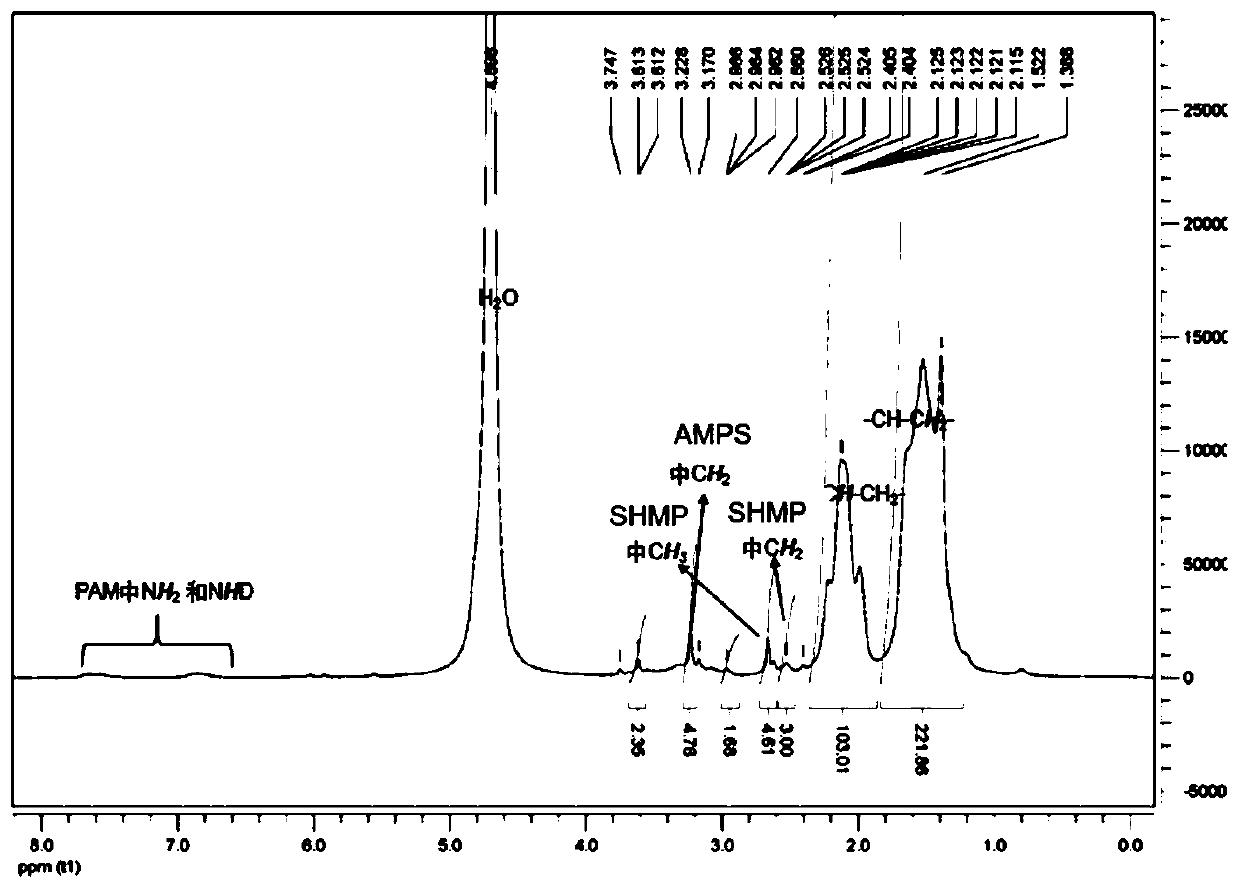

[0067] This example provides a preparation method of a salt-resistant polymer for oil displacement and the structural characterization of the polymer.

[0068] In this embodiment, the polymer structure characterization instrument is a superconducting pulse Fourier transform nuclear magnetic resonance spectrometer, produced by Bruker Corporation of the United States.

[0069] In this example, the mass percentages of the four monomers in the reaction solution are: acrylamide (AM), 20%, acrylic acid (AA), 2.5%, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) , 3.75%, sodium acryloyl-4-methylpiperazine propanesulfonate (SHMP), 0.25%.

[0070] In this embodiment, the oxidation initiator is potassium persulfate (K 2 S 2 o 8 ); the reducing initiator is sodium bisulfite (NaHSO 3 ); the azo initiator is azodiisopropylimidazoline hydrochloride (VA-044).

[0071] In the present embodiment, the synthetic formulation of the salt-resistant polymer for oil displacement is as follows (...

Embodiment 2

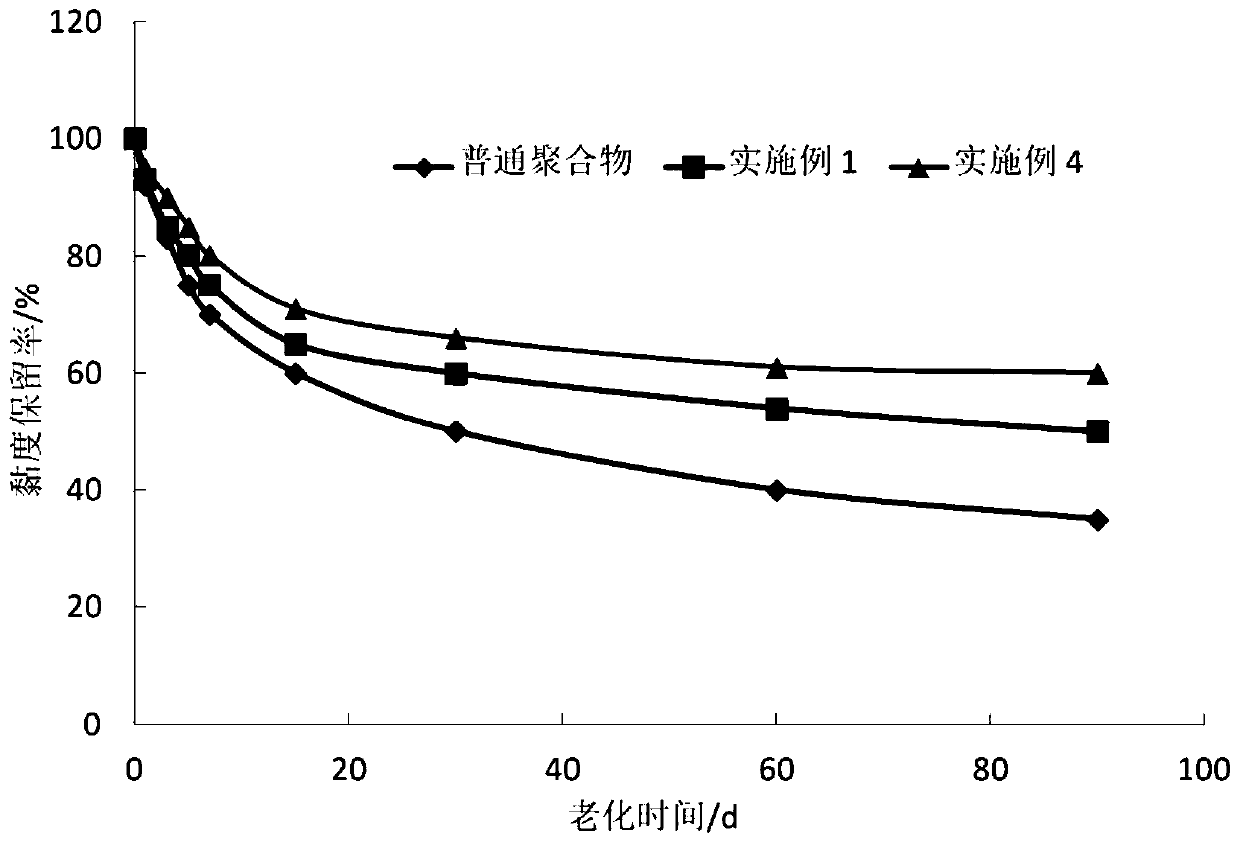

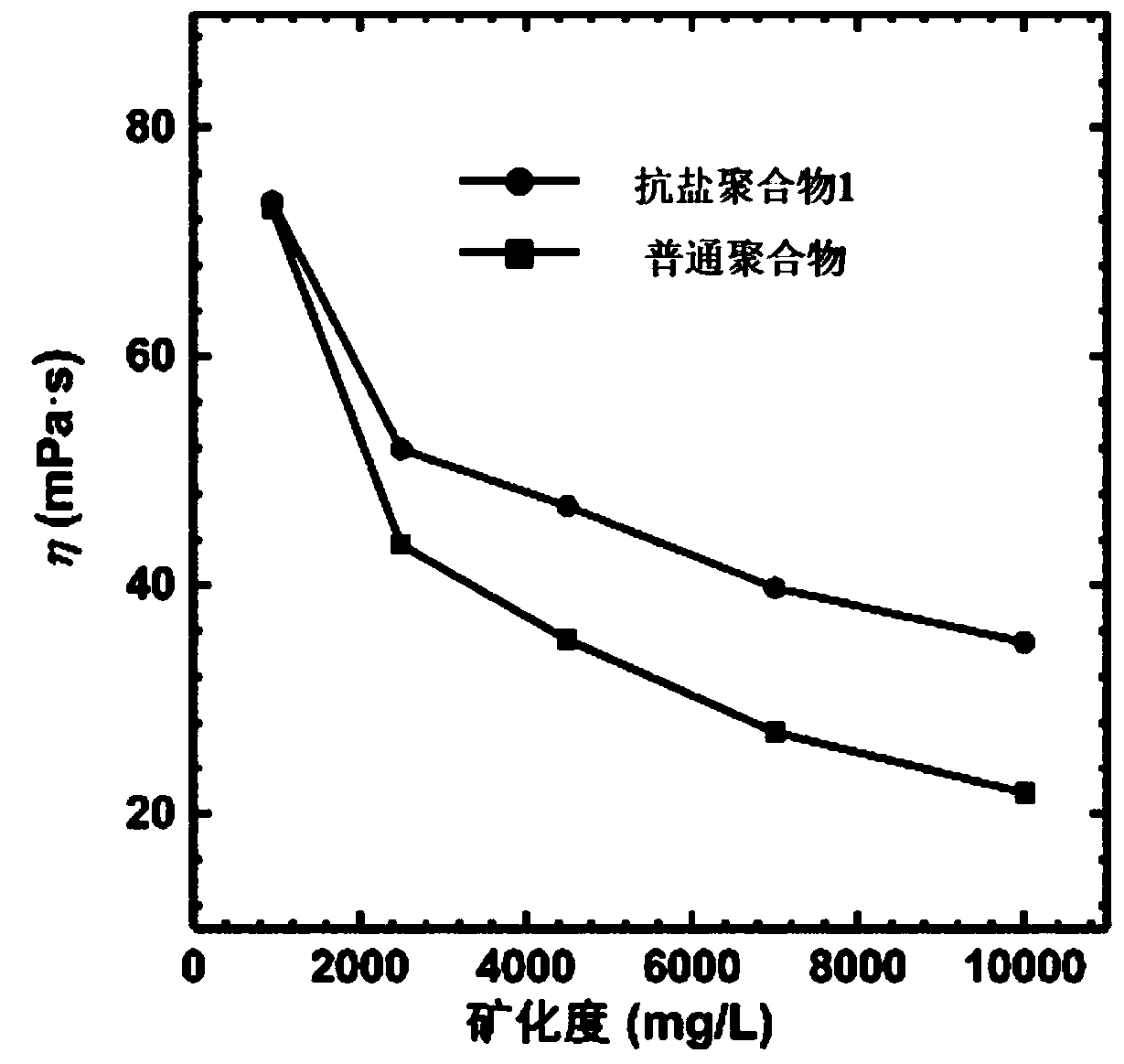

[0101] This example provides a preparation method of a salt-resistant polymer for oil displacement and a study on its salt-resistant performance.

[0102] In this example, the salt resistance performance of the polymer is characterized by the viscosity retention rate. Under the same salinity condition, the higher the viscosity retention rate of the polymer solution, the better its salt resistance.

[0103] In the present embodiment, the salt resistance performance test process of polymer is as follows:

[0104] (1) Use simulated sewage (0.095%wt NaCl solution) to configure 500g of polymer mother liquor with a concentration of 0.5%wt.

[0105] (2) Utilize simulated sewage (2%wt NaCl solution) to dilute the polymer mother liquor into 50g, the solution of concentration 0.1%wt, the salinity of the diluted solution is respectively 0.095%wt, 0.241%, 0.4%wt, 0.7 %wt, 1%wt (NaCl concentration).

[0106] (3) Using a Brookfield viscometer (DV-2+Pro Viscometer, produced by Brookfield), ...

Embodiment 3

[0130] This example provides a preparation method of a salt-resistant polymer for oil displacement and a study on its injection performance.

[0131] In this embodiment, the injection performance of the salt-resistant polymer is characterized by a core flow experiment, and the assessment index is the lower limit of the permeability of the polymer solution that can be injected into the core under the same concentration and salinity conditions. The lower limit of the polymer solution's injectable core permeability is defined when the residual resistance coefficient of the subsequent water flooding exceeds 2 / 3 of the resistance coefficient of the polymer flooding process.

[0132] In this example, the instrument used in the flow experiment is a QY-C21 automatic core displacement device, manufactured by Jiangsu Huaan Petroleum.

[0133] In this embodiment, the determination process of the lower limit of the injectable permeability of the polymer flow experiment is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com