A class of blended films based on supramolecular interaction, preparation and preparation method thereof, and applications of blended film in film devices

A thin film and blending technology, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve problems such as ineffective work, high power consumption, and inability to use portable electronic products, achieving chemical stability and Strong chemical modification and improved blendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] Implementation Case 1 Preparation of Supramolecular Interaction Blend Films

[0029] polybenzoselenodiazol-bithienocyclopentadiene alternating copolymer (hereinafter referred to as P1) and the solid of PC71BM were blended according to the mass ratio of 1:1.5, and then o-dichlorobenzene was added to form a solution of 20 mg / ml.

[0030] The solution was dropped on a quartz plate, and the blended film was obtained after natural drying.

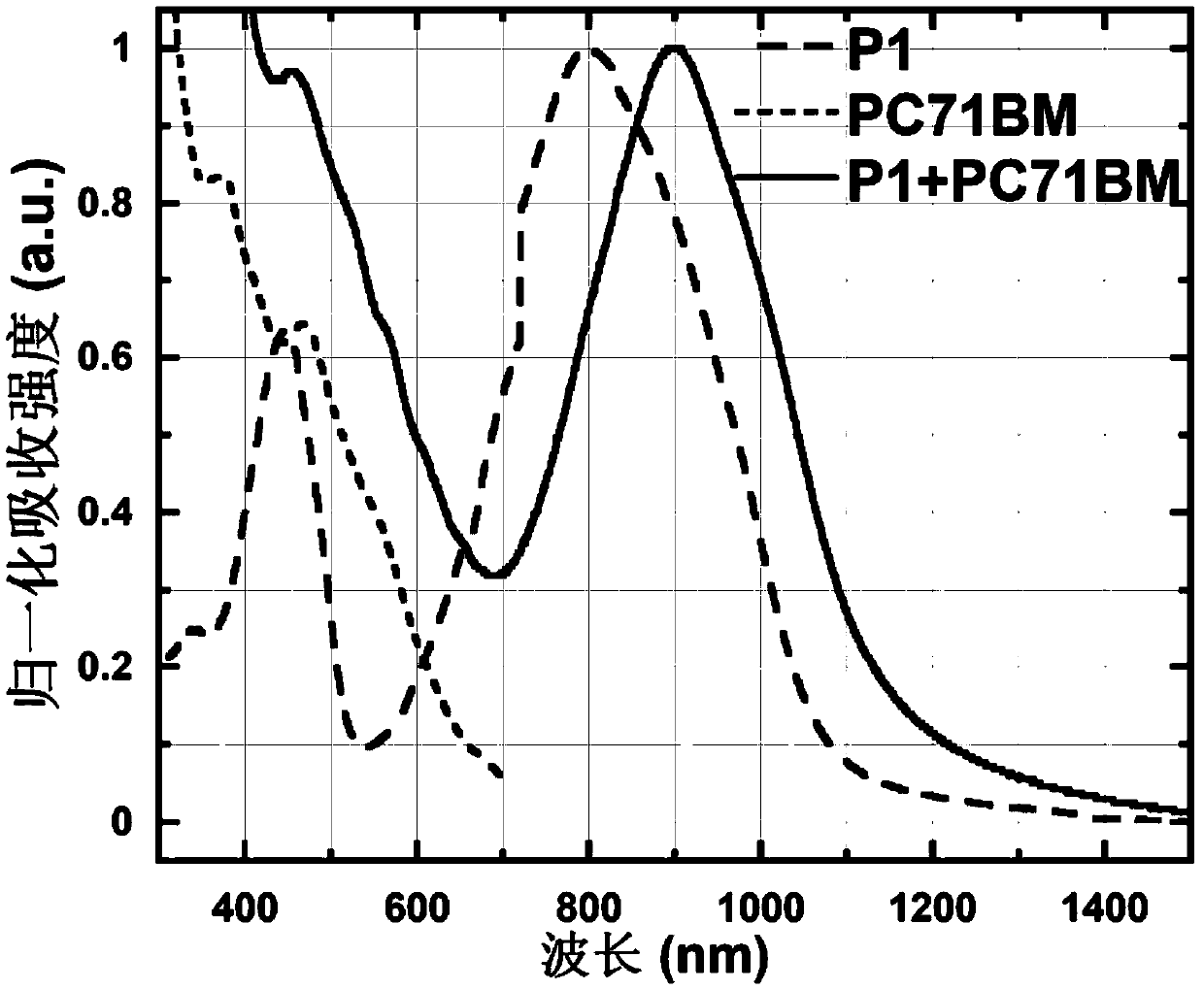

[0031] figure 1 It is the ultraviolet-visible-near-infrared absorption spectrum diagram of P1 and PC71BM blend film. It can be seen from the figure that the absorption spectrum of the blend film is red-shifted than the spectrum of P1 and PC71BM alone.

Embodiment example 2

[0032] Implementation Case 2 Preparation of Supramolecular Interaction Blend Films

[0033] Prepare P1 as a chlorobenzene solution at a concentration of 15 mg / ml; prepare PC71BM as a chlorobenzene solution at a concentration of 30 mg / ml; blend the above two solutions at a mass ratio of 4:3 by volume.

[0034] The solution was dropped on a quartz plate, and the blended film was obtained after natural drying.

Embodiment example 3

[0035] Implementation Case 3 Preparation of Organic Semiconductor Photodetector D1

[0036] The preparation process of the organic semiconductor photodetector of the present embodiment is as follows:

[0037] 1) ITO conductive glass cleaning. Place the ITO glass substrate on the film rack, and use an ultrasonic machine to ultrasonically clean it. The washing liquid is used in the order of acetone, isopropanol, detergent, deionized water and isopropanol, and then placed in an oven at 80 °C to dry.

[0038] 2) ITO is placed in an oxygen plasma etcher, using oxygen plasma (O 2Plasma) carries out the bombardment of 20 minutes, thoroughly removes possible residual organic matter on the surface of the ITO glass substrate;

[0039] 3) Prepare a hole transport layer CH8000 with a thickness of about 40 nm on the surface of the P1asma-treated ITO substrate by solution spin coating, and then thermally anneal at 150 ° C for 15 min;

[0040] 4) Place the annealed ITO substrate in a nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com