Production method of high-activity micromolecule composite edible ganoderma lucidum powder

A production method and technology of Ganoderma lucidum powder are applied in the field of production of high-activity small-molecule compound edible Ganoderma lucidum powder, which can solve the problems of easy infection of diseases and insects, long production cycle, low utilization rate, etc., so as to optimize cultivation conditions and reduce costs. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

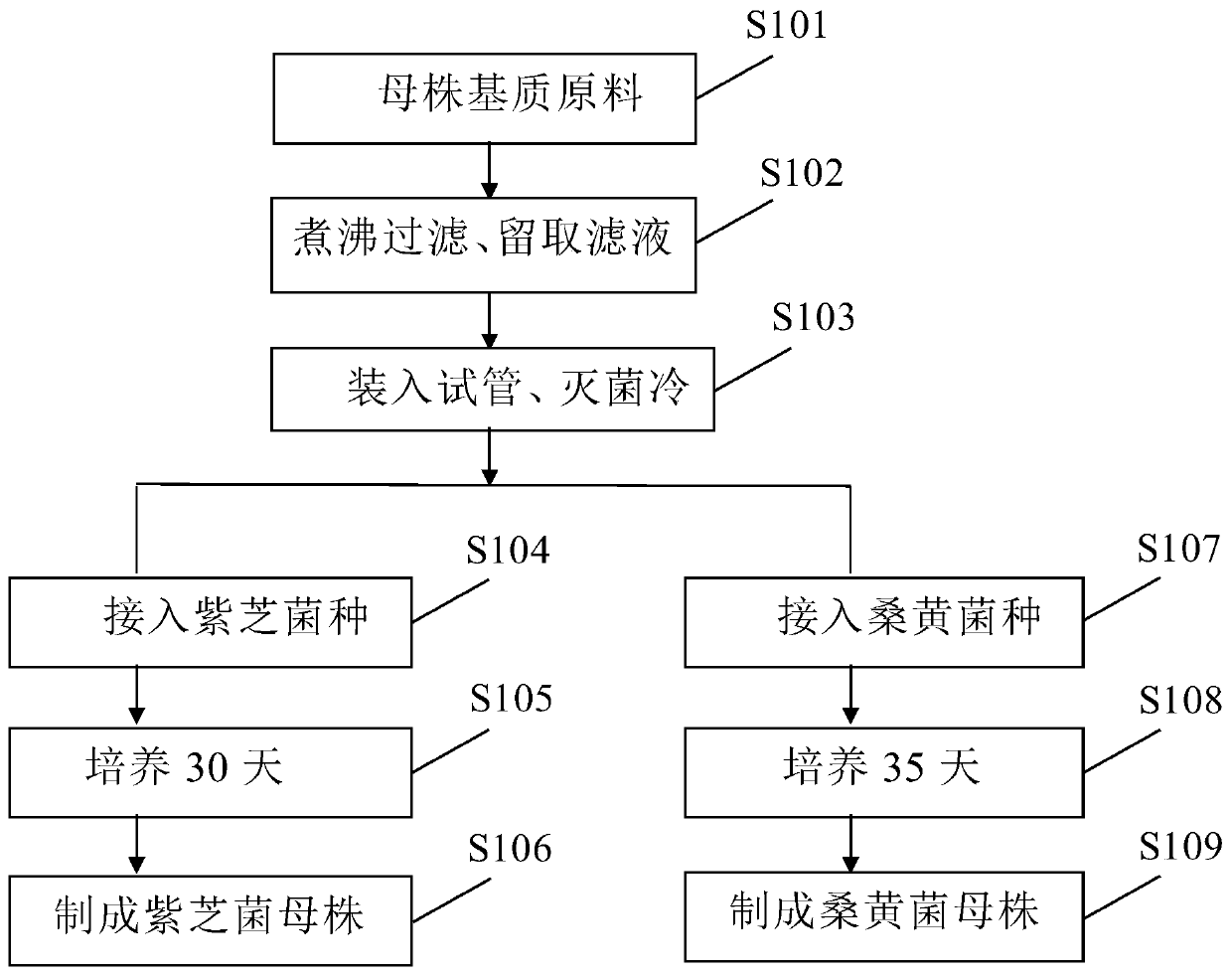

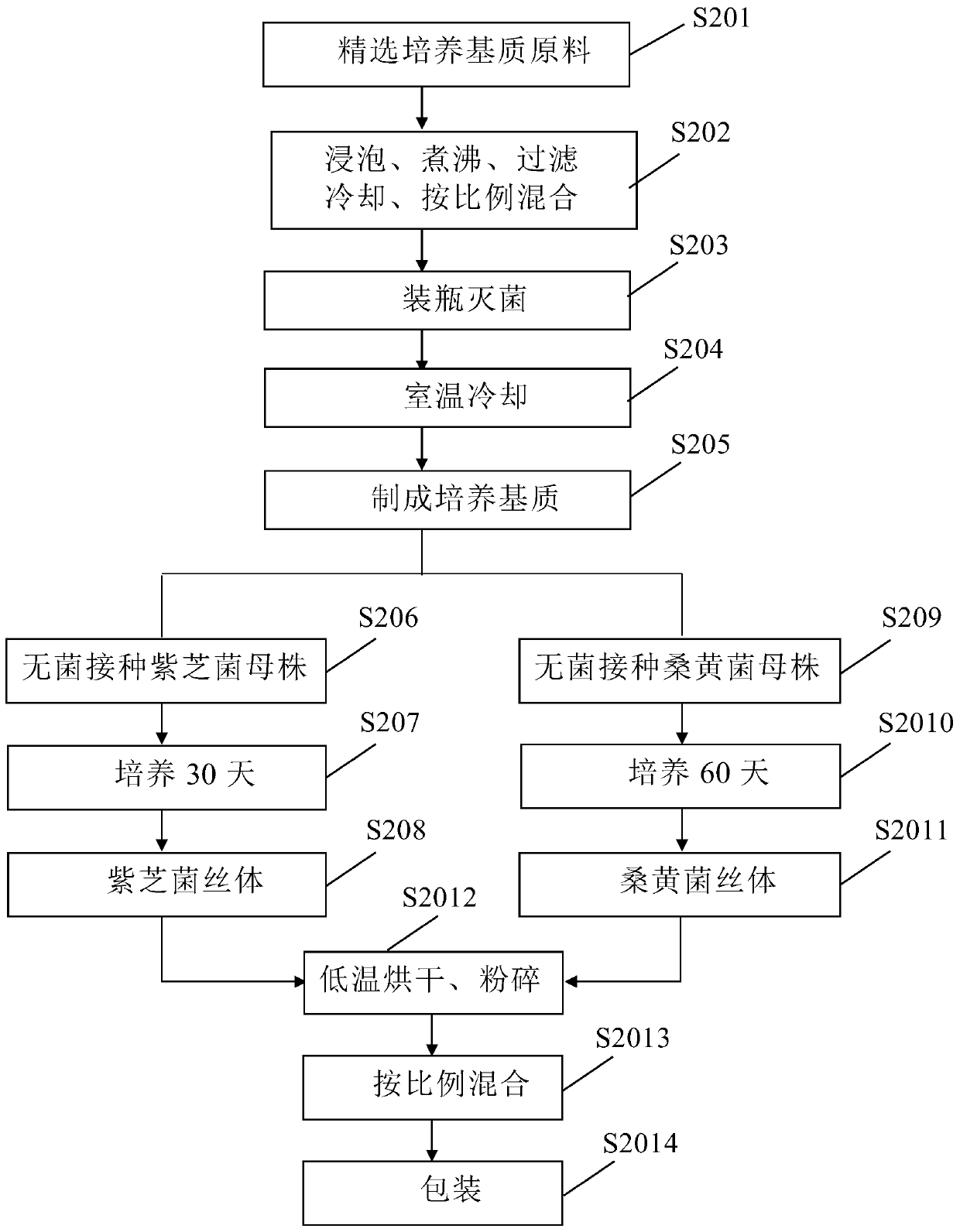

[0104] 1. Strain preparation:

[0105] 1.1 Prepare two copies of mother plant culture substrate:

[0106] ①Materials: 200g potatoes, 20g agar, 20g glucose powder, 5g multivitamin powder, 1000ml water.

[0107] ②Preparation: Peel the potatoes, slice them to a thickness of 9 mm, add water to heat, and keep boiling for 9 minutes to ensure that the slices do not rot. Filter with gauze and keep the filtrate. Add agar, glucose powder, and multivitamin powder to dissolve, then pack into clean and dry test tubes. Fill the filtrate to one-fifth of the total length of the test tube, one for every 5 tubes, stuff the tube mouth with a cotton plug, and sterilize under high pressure. Adjust the pressure cooker to 1.5 atmospheres and heat to 120°C for 35 minutes. Stop heating, depressurize and boil the pot, place it on a slope while it is hot, and adjust the filtrate to half the length of the test tube. After the filtrate is cooled and solidified, it is ready for use.

[0108] 1.2 Inocu...

Embodiment 2

[0131] 1. Strain preparation:

[0132]1.1 Prepare two copies of mother plant culture substrate:

[0133] ①Materials: 300 grams of potatoes, 40 grams of agar, 30 grams of glucose powder, 7 grams of multivitamin powder, 1200 ml of water.

[0134] ②Preparation: Peel the potatoes, slice them with a thickness of 8-10mm, add water to heat, and keep boiling for 8 minutes to ensure that the slices do not rot, filter with gauze, and keep the filtrate. Add agar, glucose powder, and multivitamin powder to dissolve, then pack into clean and dry test tubes. Fill the filtrate to one-fifth of the total length of the test tube, one for every 5 tubes, stuff the tube mouth with a cotton plug, and sterilize under high pressure. Adjust the pressure cooker to 1.5 atmospheres and heat to 120°C for 40 minutes. Stop heating, depressurize and boil the pot, place it on a slope while it is hot, and adjust the filtrate to half the length of the test tube. After the filtrate is cooled and solidified, ...

Embodiment 3

[0153] 1. Strain preparation:

[0154] 1.1 Prepare two copies of mother plant culture substrate:

[0155] ①Materials: 400 grams of potatoes, 30 grams of agar, 40 grams of glucose powder, 6 grams of multivitamin powder, 1500 ml of water.

[0156] ②Preparation: Peel the potatoes, slice them with a thickness of 8-10mm, add water to heat, keep boiling for 10 minutes to ensure that the slices are not loose, filter with gauze, and keep the filtrate. Add agar, glucose powder, and multivitamin powder to dissolve, then pack into clean and dry test tubes. Fill the filtrate to one-fifth of the total length of the test tube, one for every 5 tubes, stuff the tube mouth with a cotton plug, and sterilize under high pressure. Adjust the pressure cooker to 1.5 atmospheres and heat to 120°C for 30 minutes. Stop heating, depressurize and boil the pot, place it on a slope while it is hot, and adjust the filtrate to half the length of the test tube. After the filtrate is cooled and solidified,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com