Method for preparing graphene film on metal surface

A graphene film and metal surface technology, applied in the field of graphene film preparation, can solve the problems of high cost, high electrodeposition temperature, small area, etc., and achieve the effects of controllable shape, simple process and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

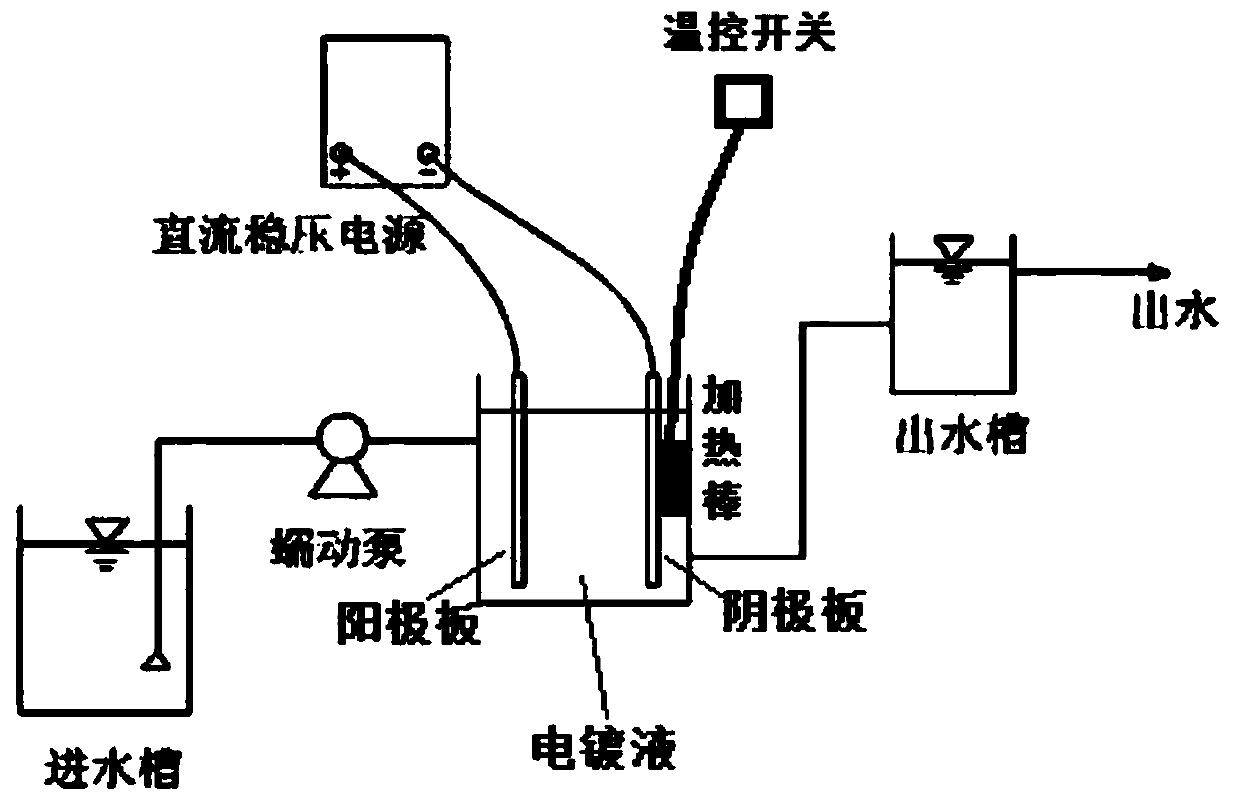

Method used

Image

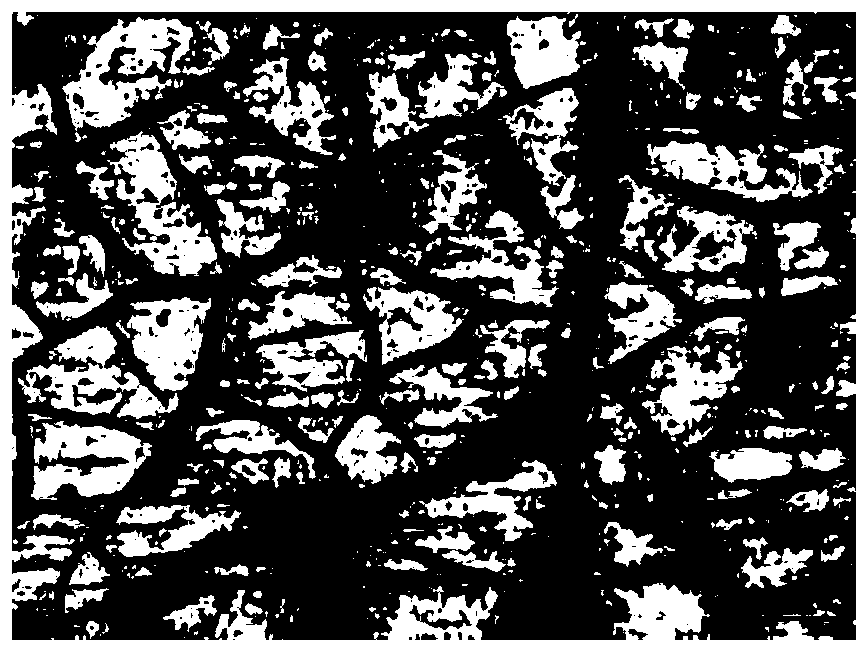

Examples

Embodiment 1

[0027] Graphene film preparation method of the present invention is as follows:

[0028] (1) Configure the basic plating solution.

[0029] Main salt: NiSO 4 ·6H 2 O, content 210g / L; anode activator: NiCl 2 , content 35g / L; buffer: boric acid, content 24g / L; conductive salt: sodium chloride, content 20g / L; carbon source: lysine, content 0.25mol / L. Using 10wt% H 2 SO 4 The solution was adjusted to pH 4.

[0030] (2) Pretreatment of the base material.

[0031] The base material is H62 brass sheet.

[0032]Electro-cleaning: Electro-cleaning fluid configuration is as follows: NaOH 40g / L, NaOH 3 PO 4 160g / L, Na 2 CO 3 40g / L, NaCl 5g / L; process parameters are as follows: voltage: 10V; time: 32s.

[0033] Activation: prepare No. 3 activation solution for activation: citric acid (C 6 h 8 o 7 ·H 2 O) 140g / L, sodium citrate (C 6 h 5 Na 3 o 7 2H 2 O) 90g / L, NiCl 2 3g / L; process parameters are as follows: voltage: -20V; time: 45s.

[0034] Washing: Rinse with dei...

Embodiment 2

[0040] Graphene film preparation method of the present invention is as follows:

[0041] (1) Configure the basic plating solution.

[0042] Main salt: CuSO 4 ·6H 2 O, content 190g / L; anode activator: NiCl 2 , content 38g / L; buffer: boric acid, content 25g / L; conductive salt: sodium chloride, content 12g / L; carbon source: ascorbic acid, content 0.45mol / L. Using 10wt% H 2 SO 4 The pH of the solution was adjusted to 4.5.

[0043] (2) Pretreatment of the base material.

[0044] The base material is 304 stainless steel sheet.

[0045] Electro-cleaning: Electro-cleaning fluid configuration is as follows: NaOH 30g / L, NaOH 3 PO 4 170g / L, Na 2 CO 3 30g / L, NaCl 6g / L; process parameters are as follows: voltage: 12V; time: 28s.

[0046] Activation: Firstly prepare No. 2 activation solution for activation: HCl (36-38wt%) 25g / L, NaCl 140g / L; process parameters are as follows: voltage: -8V; time: 60s. Then prepare No. 3 activation solution for activation: citric acid (C 6 h ...

Embodiment 3

[0053] Graphene film preparation method of the present invention is as follows:

[0054] (1) Configure the basic plating solution.

[0055] Main salt: CoSO 4 ·6H 2 O, content 230g / L; anode activator: NiCl 2 , content 31g / L; buffer: boric acid, content 26g / L; conductive salt: sodium chloride, content 28g / L; carbon source: arginine, content 0.1mol / L. Using 10wt% H 2 SO 4 The solution was adjusted to pH 3.

[0056] (2) Pretreatment of the base material.

[0057] The base material is T1 titanium alloy sheet.

[0058] Electro-cleaning: Electro-cleaning fluid configuration is as follows: NaOH 50g / L, NaOH 3 PO 4 150g / L, Na 2 CO 3 50g / L, NaCl4g / L; process parameters are as follows: voltage: 8V; time: 36s.

[0059] Activation: firstly prepare No. 1 activation solution for activation, H 2 SO 4 (95~98wt%) 60g / L, (NH 4 ) 2 SO 4 115 g / L; process parameters are as follows: voltage: -10V; time: 30s. Then prepare No. 3 activation solution for activation: citric acid (C 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com