Method for preparing porous carbon materials with different morphologies through ultrasonic spray pyrolysis regulation and control

A porous carbon material and ultrasonic spray technology, applied in the field of porous carbon materials, can solve the problems of inability to prepare porous carbon, single and uncontrollable morphology, etc., and achieve the effects of easy control of reaction, beautiful appearance and uniform size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

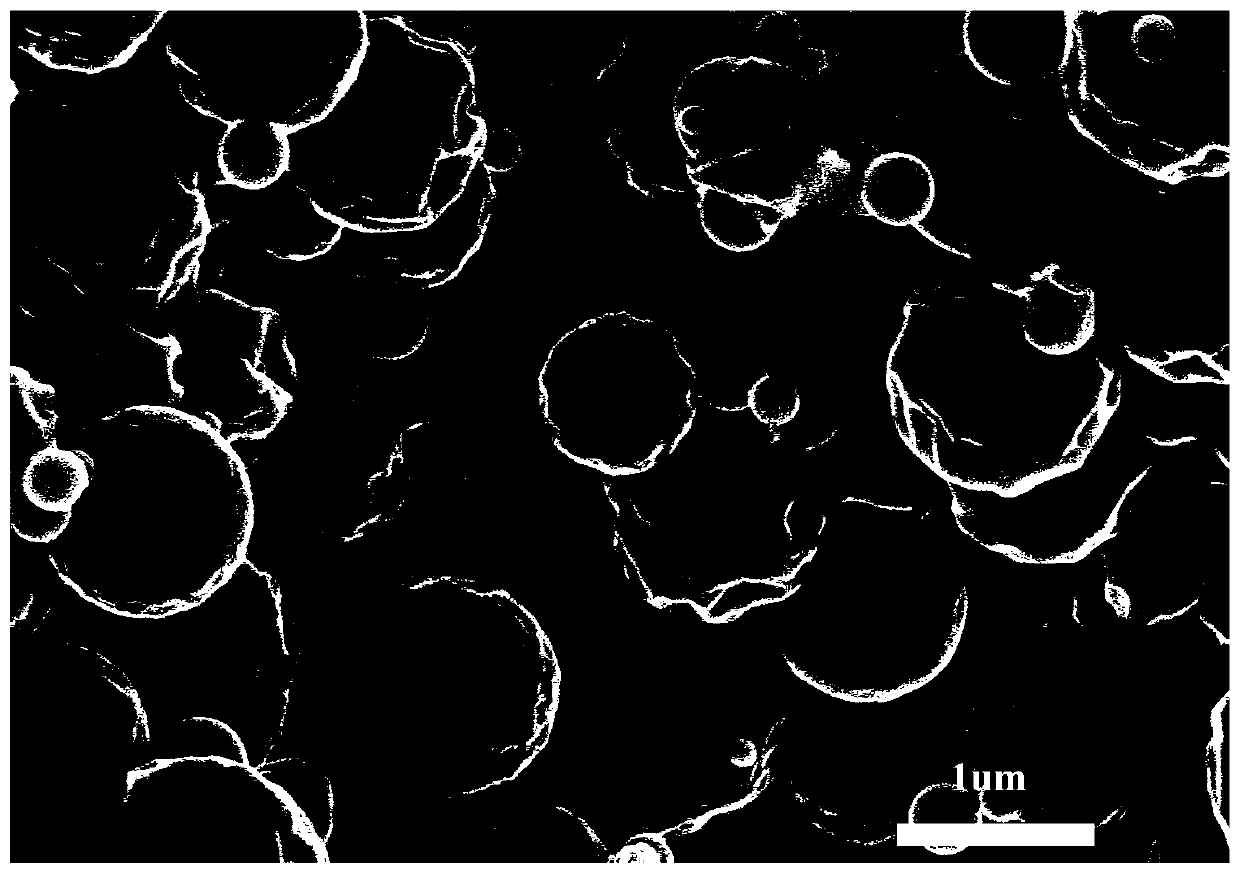

[0044] In this example, the blood cell-like porous carbon prepared by controlling different proportions through ultrasonic atomization specifically includes the following steps:

[0045](1) Weigh 3g of sucrose and dissolve it in 50ml of deionized water, weigh 1g of zinc nitrate solid, dissolve it in the sucrose solution, and ultrasonicate it for 0.5h at room temperature to make a uniformly dispersed solution to obtain sucrose: zinc nitrate=3: 1 precursor solution.

[0046] (2) The precursor solution is atomized into droplets through an ultrasonic atomizer, and loaded into a preheated tube furnace (700°C) with an inert gas at a certain flow rate, and the droplets undergo solvent evaporation in the tube furnace, Droplet concentration, dry crystallization and thermal decomposition processes, finally forming solid powder particles.

[0047] (3) Wash the collected solid particles with deionized water, suction filter, dry, grind and other processes, and then prepare an acid solutio...

Embodiment 2

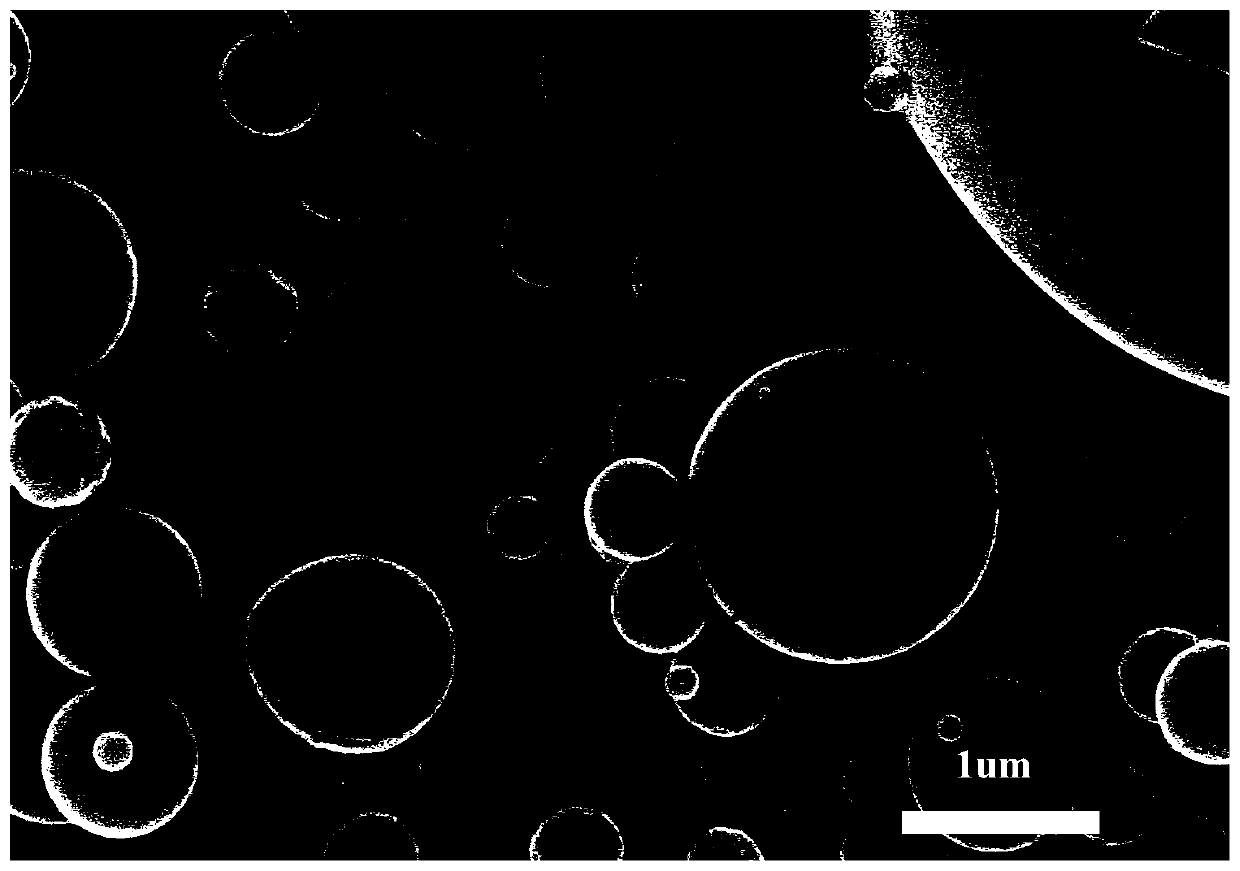

[0050] This example is the same as Example 1, except that the weighed sucrose and zinc nitrate are 1g and 1g respectively, and the other steps are identical.

[0051] The porous carbon material SEM experiment result of the porous carbon that present embodiment prepares has spherical appearance is as follows figure 2 shown.

Embodiment 3

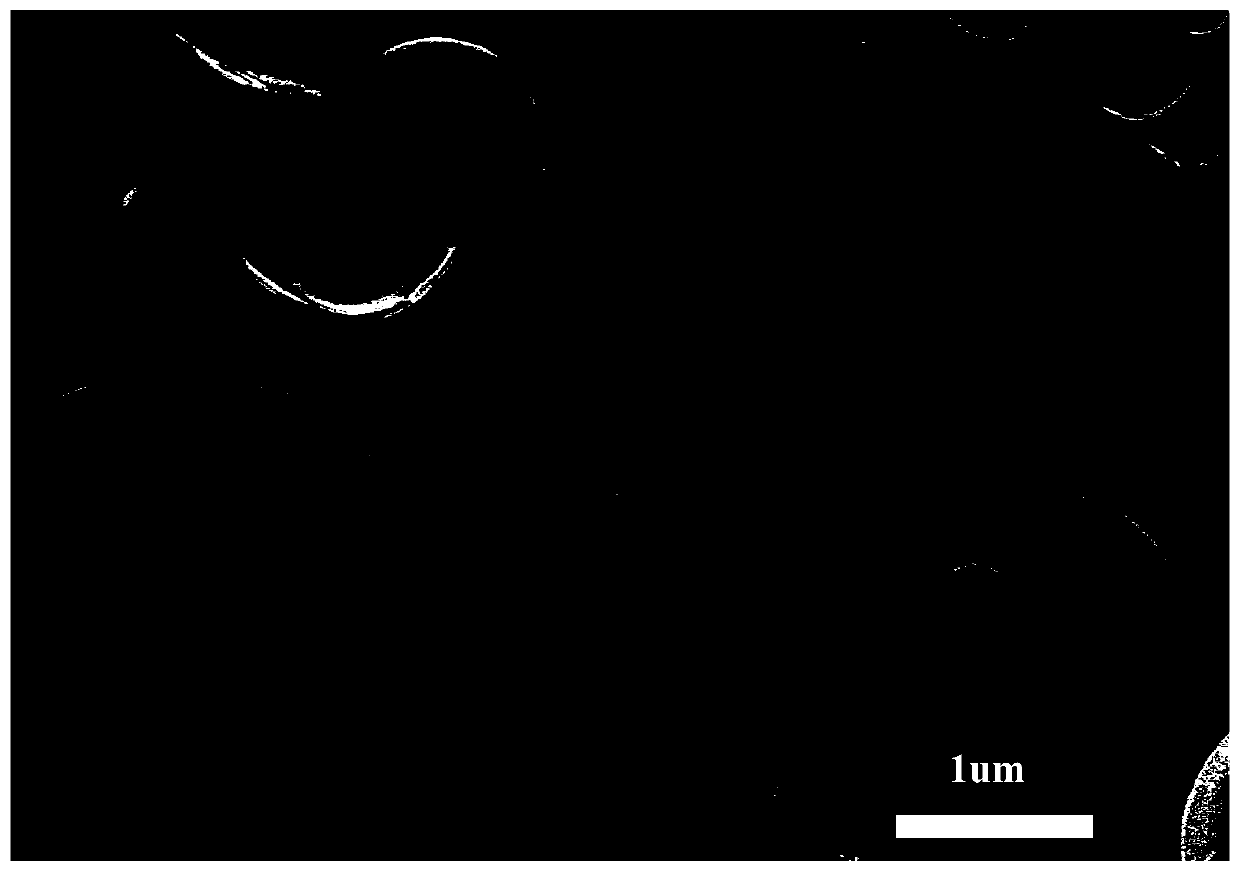

[0053] This example is the same as Example 1, except that the weighted sucrose and zinc nitrate are 1g and 2g respectively, and the other steps are identical.

[0054] The porous carbon material prepared in this example has pomegranate-like appearance SEM experimental results as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com