APAO modified styrene-acrylic emulsion and preparation method thereof

A styrene-acrylic emulsion and modification technology, applied in the direction of coating, etc., can solve the problems of poor anti-sag performance and unsatisfactory performance, and achieve the effect of good adhesion, good adhesion, and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

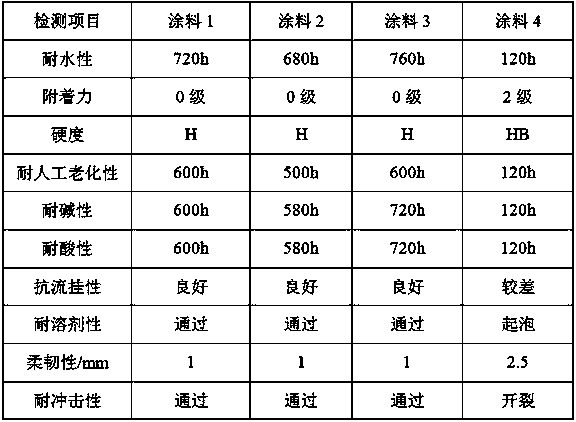

Examples

Embodiment 1

[0027] An APAO modified styrene-acrylic emulsion, the components of which are in parts by weight: 6.0 parts of APAO, 15.0 parts of methyl methacrylate, 12.0 parts of butyl acrylate, 4.0 parts of glycidyl acrylate, 28.0 parts of styrene, acrylic acid 2.5 parts of hydroxyethyl ester, 3.8 parts of acrylic acid, 0.2 parts of ammonium persulfate, 0.7 parts of sodium bicarbonate, 4.5 parts of triethylamine, 3.0 parts of emulsifier, 7.0 parts of ethylene glycol monobutyl ether, and 130.0 parts of deionized water.

[0028] A kind of preparation method of APAO modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0029] 1) Weigh in proportion, add methyl methacrylate, butyl acrylate, hydroxyethyl acrylate and acrylic acid in sequence and stir evenly to obtain mixed liquid I;

[0030] 2) Weigh in proportion, add styrene, APAO, ethylene glycol monobutyl ether, glycidyl acrylate in sequence and stir evenly to obtain the mixed solution II;

[0031] ...

Embodiment 2

[0034] An APAO modified styrene-acrylic emulsion, the components of which are in parts by weight: 5.0 parts of APAO, 12.0 parts of methyl methacrylate, 5.0 parts of acrylonitrile, 6.0 parts of butyl acrylate, and 9.0 parts of lauryl methacrylate , 4.0 parts of glycidyl acrylate, 30.0 parts of styrene, 2.0 parts of hydroxybutyl acrylate, 3.8 parts of acrylic acid, 0.3 parts of ammonium persulfate, 0.8 parts of sodium bicarbonate, 4.0 parts of ammonia water, 3.5 parts of emulsifier, butylated diethylene glycol 7.0 parts of ether, 140.0 parts of deionized water.

[0035] A kind of preparation method of APAO modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0036] 1) Weigh in proportion, add methyl methacrylate, acrylonitrile, butyl acrylate, lauryl methacrylate, hydroxybutyl acrylate, and acrylic acid in sequence and stir evenly to obtain a mixed solution I;

[0037] 2) Weigh in proportion, add styrene, APAO, diethylene glycol butyl et...

Embodiment 3

[0041] An APAO modified styrene-acrylic emulsion, the components of which are: 7.0 parts of APAO, 10.0 parts of isobornyl acrylate, 6.0 parts of acrylamide, 7.0 parts of octadecyl methacrylate, and isooctyl methacrylate 5.0 parts, 5.0 parts of glycidyl acrylate, 31.0 parts of styrene, 2.0 parts of hydroxyethyl methacrylate, 4.0 parts of acrylic acid, 0.3 parts of ammonium persulfate, 0.8 parts of sodium bicarbonate, 5.4 parts of triethylamine, 3.2 parts of emulsifier , 8.0 parts of ethylene glycol monobutyl ether, and 143.0 parts of deionized water.

[0042] A kind of preparation method of APAO modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0043] 1) Weigh in proportion, add isobornyl acrylate, acrylamide, stearyl methacrylate, isooctyl methacrylate, hydroxyethyl methacrylate, and acrylic acid in sequence and stir evenly to obtain a mixed solution I;

[0044] 2) Weigh in proportion, add styrene, APAO, ethylene glycol monobutyl et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com