Phosphorus-doped cobalt oxide iron-nitrogen-doped carbon nanofiber composite material as well as preparation method and application thereof

A technology of carbon nanofibers and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as large overpotential and slowness, and achieve electrical conductivity Good, stable physical and chemical properties, and the effect of increasing the active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

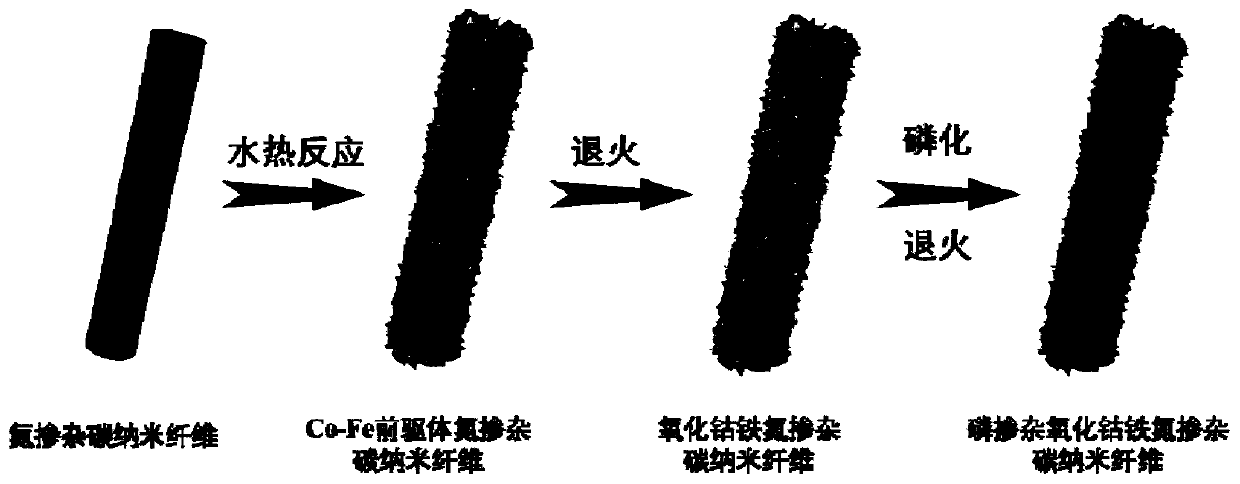

[0030] Such as figure 1 As shown, this embodiment provides a method for preparing phosphorus-doped cobalt oxide, iron-nitrogen-doped carbon nanofiber composite material, and the specific steps are as follows:

[0031] Step 1: Dissolve cobalt nitrate hexahydrate, ferric nitrate nonahydrate, and ammonium fluoride in deionized water at a molar ratio of 1:2:10, and ultrasonically treat them for 10 minutes to disperse them evenly to obtain solution A;

[0032] Step 2: Add nitrogen-doped carbon nanofibers to the solution A prepared in step 1, ultrasonically disperse for 1 hour, and then conduct a hydrothermal reaction at a reaction temperature of 120°C and a reaction time of 10 hours. After the reaction is completed, cool to room temperature, The sample was washed with a mixed solution of ethanol and water, and dried at 80°C for 12 hours to obtain a precursor;

[0033] Step 3: annealing the precursor prepared in step 2 in a nitrogen atmosphere at 350° C. at a heating rate of 5° C. / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com